Preparation method of corrosion-resistant epoxy emulsion for high-pressure pipeline yarn

A high-pressure pipeline and corrosion-resistant technology, which is applied in the field of epoxy emulsion preparation for corrosion-resistant high-pressure pipeline yarns, can solve the problem that corrosion cannot be effectively enhanced, and achieves improved scrub resistance, corrosion resistance, and anti-corrosion properties. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments.

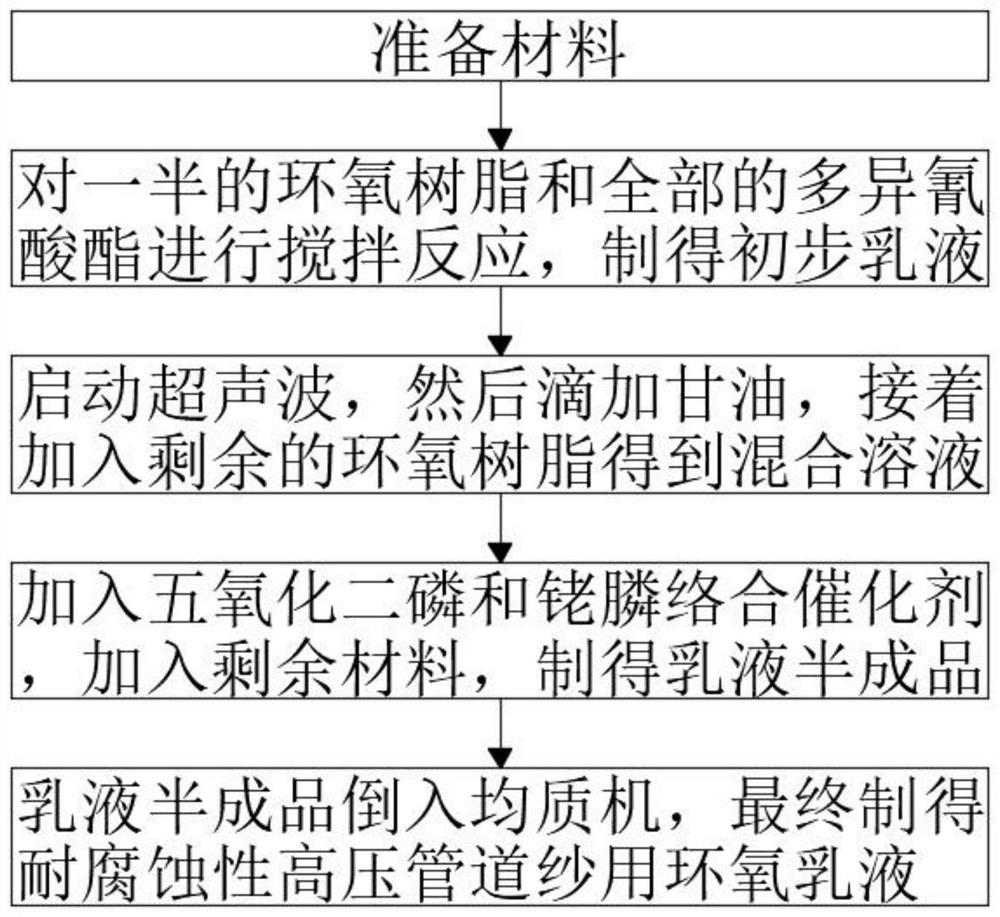

[0024] refer to figure 1 , embodiment one

[0025] A method for preparing epoxy emulsion for corrosion-resistant high-pressure pipe yarn is proposed in this embodiment, comprising the following steps:

[0026] S1: Prepare materials, including 100 parts of epoxy resin, 39 parts of polyisocyanate, 19 parts of glycerin, 13 parts of phosphorus pentoxide, 14 parts of additives, 14 parts of grass-wood mixture and 5 parts of rhodium phosphine Complex catalyst, additives include special lime powder and special gypsum powder, grass and wood mixture includes plant ash and plant fiber, epoxy resin is bisphenol A type epoxy resin, which is made by mixing epoxy E51, epoxy E44 and epoxy E20 The ratio of special lime powder and special gypsum powder in the additive is controlled at 45% to 55%: 45% to 55%. The preparation method of special lime powder is to select suitable lime powder an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com