Method for preparing penicillin sulfoxide ester through continuous flow

A penicillin and sulfoxide ester technology, which is applied in the field of continuous flow preparation of penicillin sulfoxide ester, can solve the problem of low selectivity, achieve simple operation, high production capacity per unit area, and improve process economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

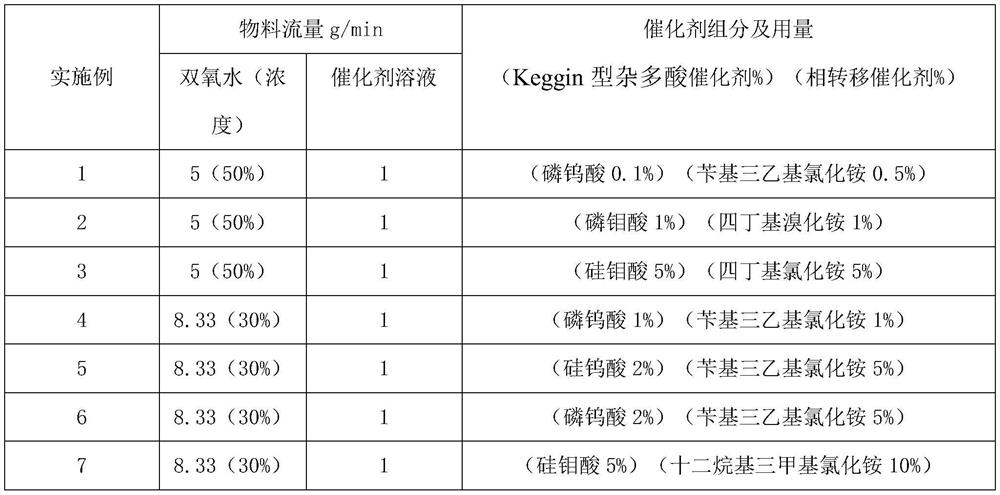

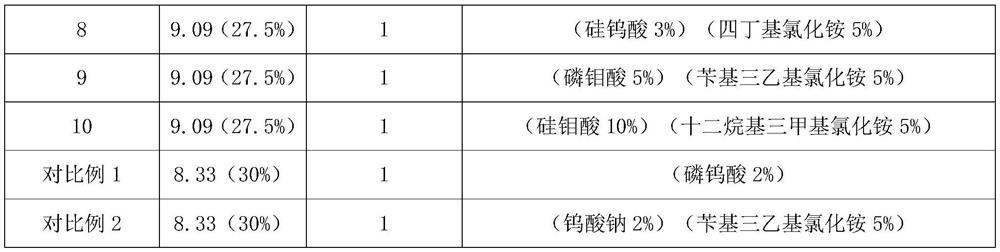

Examples

Embodiment

[0034] Penicillin G potassium ester synthesis:

[0035] 4L of dichloromethane, 2Kg of penicillin G potassium, 1.165Kg of p-nitrobenzyl bromide and 100g of triethylbenzyl ammonium chloride were successively added into a 10-liter glass reactor. Stir and heat up, reflux for 6-7 hours, HPLC tracking, after the reaction is completed, cool down to room temperature, add 2L of water, stir evenly, let stand for 30 minutes, and release the organic phase. The aqueous phase was extracted twice with 0.5L dichloromethane, the organic phase was combined, and the organic phase was rinsed twice with 0.5L water, and the organic phase after rinsing was set aside, and the concentration of penicillin G potassium ester was 27.66%.

[0036] Continuous flow method for preparing penicillin sulfoxide ester:

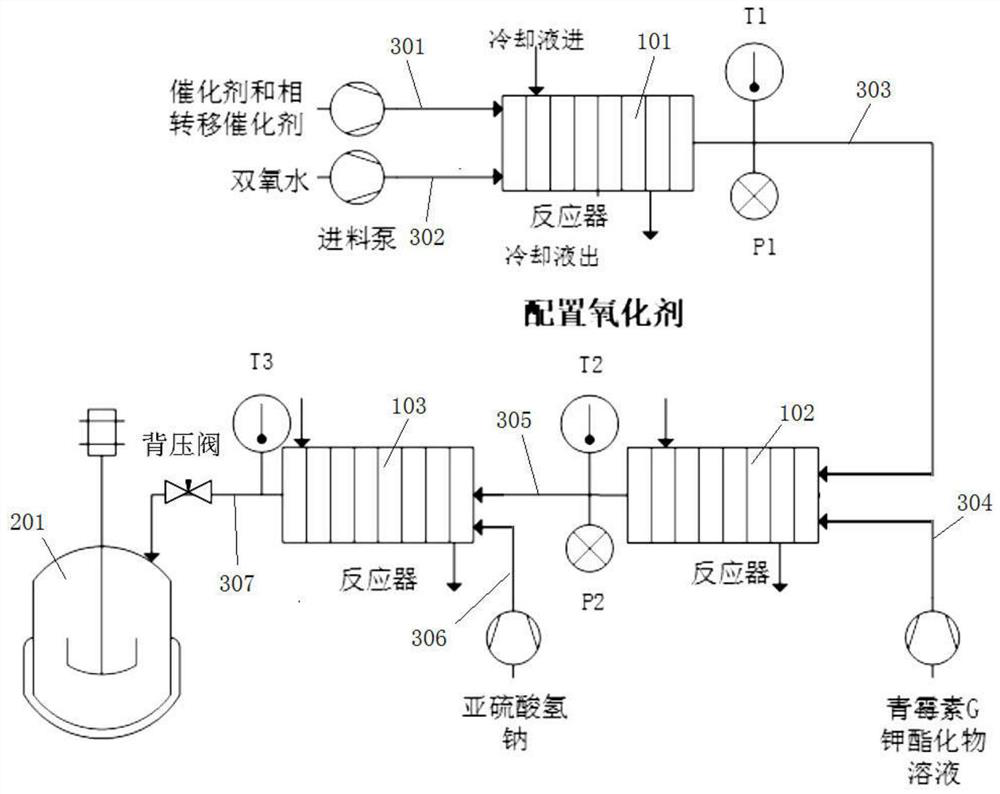

[0037] The above device was used, wherein the first reactor 101, the second reactor 102, and the third reactor 103 were purchased from Corning Reactor Technology Co., Ltd., model: Lab Reactor&LFR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com