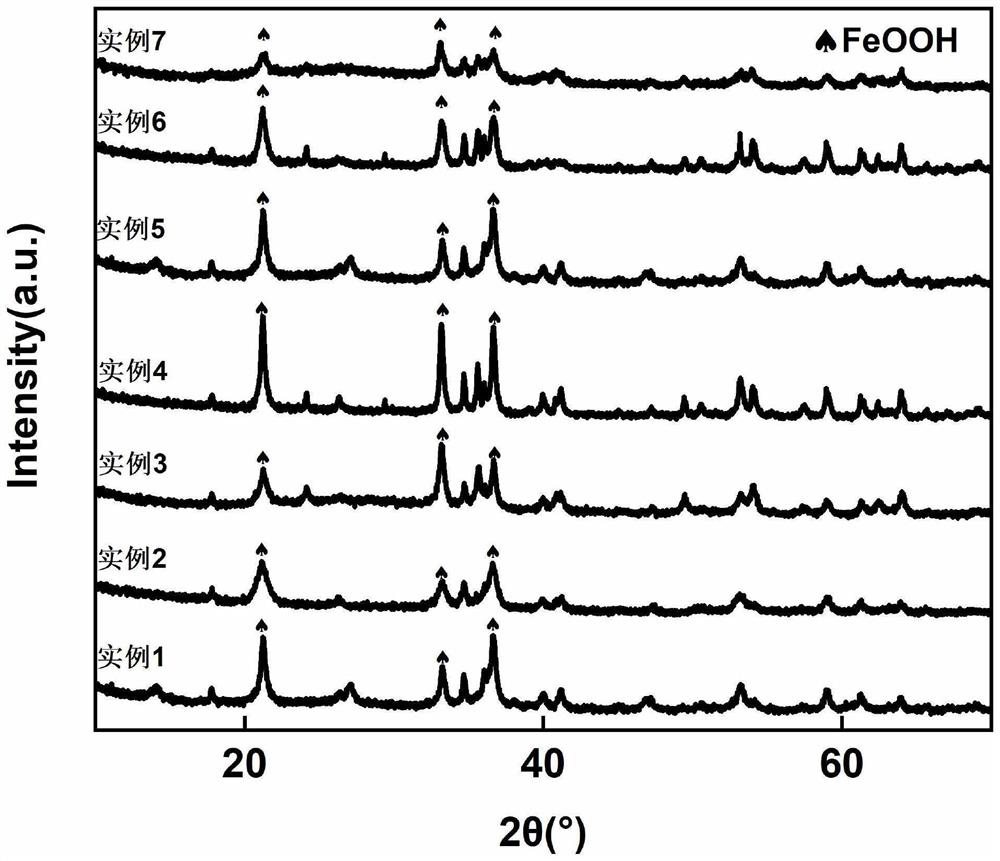

Nano hydrated iron oxide as well as preparation method and application thereof

A hydrated iron oxide, nanotechnology, applied in iron oxide, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of expensive mesoporous materials, uneven loading, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing nanometer hydrated iron oxide, comprising the following steps:

[0024] (1) dissolving water-soluble iron salt and citric acid in water to obtain A mixed solution;

[0025] (2) Precipitating agent and ethanol are dissolved in water to obtain B mixed solution;

[0026] (3) adding the B mixed solution obtained in the step (2) dropwise to the A mixed solution obtained in the step (1) to carry out a hydrothermal reaction to obtain nanometer hydrated iron oxide;

[0027] The steps (1) and (2) are not in sequence.

[0028] The invention dissolves water-soluble iron salt and citric acid in water to obtain A mixed solution. In the present invention, the iron salt in the aqueous solution is used as the iron source, and the citric acid is used as the dispersant to uniformly disperse the water-soluble iron salt, and to control the precipitation rate during the subsequent hydrothermal reaction process to avoid rapid growth of particle...

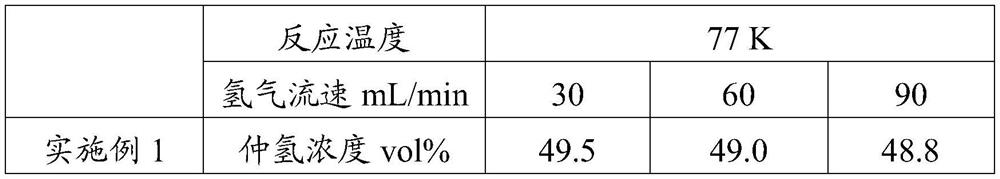

Embodiment 1

[0049] (1) Dissolve 20.2g ferric nitrate and 10.5g citric acid in 100mL deionized water to obtain Fe 3+ Concentration is 0.5mol / L and the concentration of citric acid is A mixed liquor of 0.5mol / L;

[0050] (2) Get 12.0g urea and 2.3g ethanol and dissolve in 50mL deionized water to obtain a B mixed solution whose urea concentration is 4mol / L and ethanol concentration is 1mol / L;

[0051] (3) Add the B mixed solution obtained in step (2) dropwise to the A mixed solution obtained in step (1) with a peristaltic pump at a speed of 1 mL / min, and use a magnetic stirrer at 1000 r / min while adding B mixed solution dropwise. Stir at a rate of 1 min, and continue to stir for 10 min after the B mixed solution is dripped to obtain the C mixed solution, wherein the volume ratio of the A mixed solution to the B mixed solution is 2:1;

[0052] (4) Pour the mixed liquid C obtained in step (3) into a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into an oven, and reac...

Embodiment 2

[0055] (1) Dissolve 4.0g ferric nitrate and 4.2g citric acid in 100mL deionized water to obtain Fe 3+ A mixed solution whose concentration is 0.1mol / L and citric acid concentration is 0.2mol / L;

[0056] (2) Dissolve 3.0 g of urea and 9.2 g of ethanol in 50 mL of deionized water to obtain a B mixture with a urea concentration of 1 mol / L and an ethanol concentration of 4 mol / L:

[0057] (3) Add the B mixed solution obtained in step (2) dropwise to the A mixed solution obtained in step (1) with a peristaltic pump at a speed of 8mL / min, while dripping the B mixed solution, use a magnetic stirrer at a speed of 800r / min. Stir at a rate of 1 min, and continue to stir for 15 minutes after the B mixed solution is dripped to obtain the C mixed solution, wherein the volume ratio of the A mixed solution to the B mixed solution is 2:1;

[0058] (4) Pour the C mixed solution obtained in step (3) into a hydrothermal kettle, then put the hydrothermal reaction kettle into an oven, react at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com