Method for extracting valuable elements from coal gangue

A technology of valuable elements and coal gangue, applied in chemical instruments and methods, silica, inorganic chemistry, etc., to achieve the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

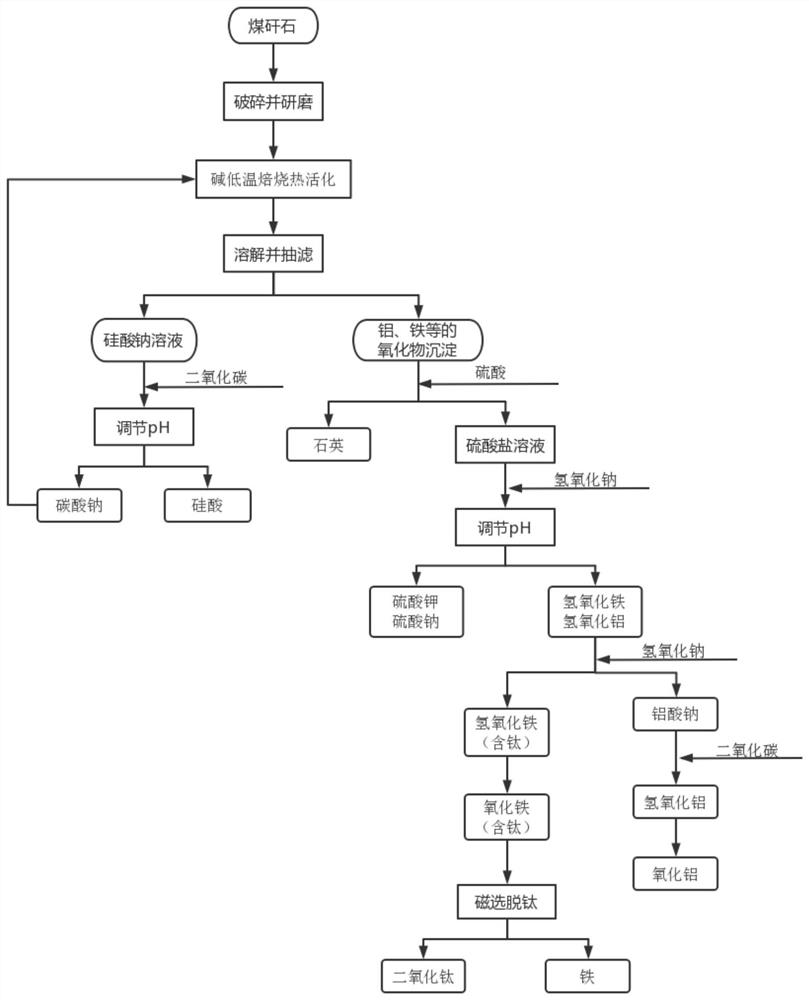

[0049] This embodiment provides a method for extracting valuable elements from coal gangue, such as figure 1 shown, including the following steps:

[0050] S1: Crush and grind coal gangue to 74 μm, remove carbon and sulfur, mix it with sodium carbonate at a ratio of 1:1.5, and roast it in a trolley furnace at 830°C for 120 minutes to obtain activated minerals. After activation, most of the silica is converted into sodium silicate.

[0051] S2: Dissolving the activated mineral in water at 85° C., stirring continuously, and suction filtering to obtain sodium silicate solution and slag.

[0052] S3: Introduce carbon dioxide into the sodium silicate solution to precipitate silicic acid, and produce sodium carbonate for recycling;

[0053] After sulfuric acid is added to the slag for dissolution, a sediment and a supernatant are obtained; the sediment is crystalline insoluble silicon dioxide, and the supernatant is a solution rich in iron and aluminum ions.

[0054] S4: Using so...

Embodiment 2

[0060] This embodiment provides a method for extracting valuable elements from coal gangue, such as figure 1 shown, including the following steps:

[0061] S1: Crush and grind coal gangue to 36 μm, remove carbon and sulfur, mix it with sodium carbonate at a ratio of 1:1.2, and roast it in a trolley furnace at 830°C for 70 minutes to obtain activated minerals. After activation, most of the silica is converted into sodium silicate.

[0062] S2: Dissolving the activated mineral in water at 80° C., stirring continuously, and suction filtering to obtain sodium silicate solution and slag.

[0063] S3: Introduce carbon dioxide into the sodium silicate solution to precipitate silicic acid, and produce sodium carbonate for recycling;

[0064] After sulfuric acid is added to the slag for dissolution, a sediment and a supernatant are obtained; the sediment is crystalline insoluble silicon dioxide, and the supernatant is a solution rich in iron and aluminum ions.

[0065] S4: Using sod...

Embodiment 3

[0071] This embodiment provides a method for extracting valuable elements from coal gangue, such as figure 1 shown, including the following steps:

[0072] S1: Crush and grind coal gangue to 15 μm, remove carbon and sulfur, mix it with sodium carbonate at a ratio of 1:1.2, and roast it in a trolley furnace at 830°C for 70 minutes to obtain activated minerals. After activation, most of the silica is converted into sodium silicate.

[0073] S2: Dissolving the activated mineral in water at 90° C., stirring continuously, and suction filtering to obtain sodium silicate solution and slag.

[0074] S3: Introduce carbon dioxide into the sodium silicate solution to precipitate silicic acid, and produce sodium carbonate for recycling;

[0075] After sulfuric acid is added to the slag for dissolution, a sediment and a supernatant are obtained; the sediment is crystalline insoluble silicon dioxide, and the supernatant is a solution rich in iron and aluminum ions.

[0076] S4: Using sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com