Preparation method of nitrogen-doped carbon nanotube wave-absorbing agent

A nanotube and azacarbon technology, applied in the directions of carbon nanotubes, nanocarbons, electrical components, etc., can solve the problems of tube wall distortion and low doping amount, and achieve simple process, easy large-scale production, and efficient electromagnetic wave absorption. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

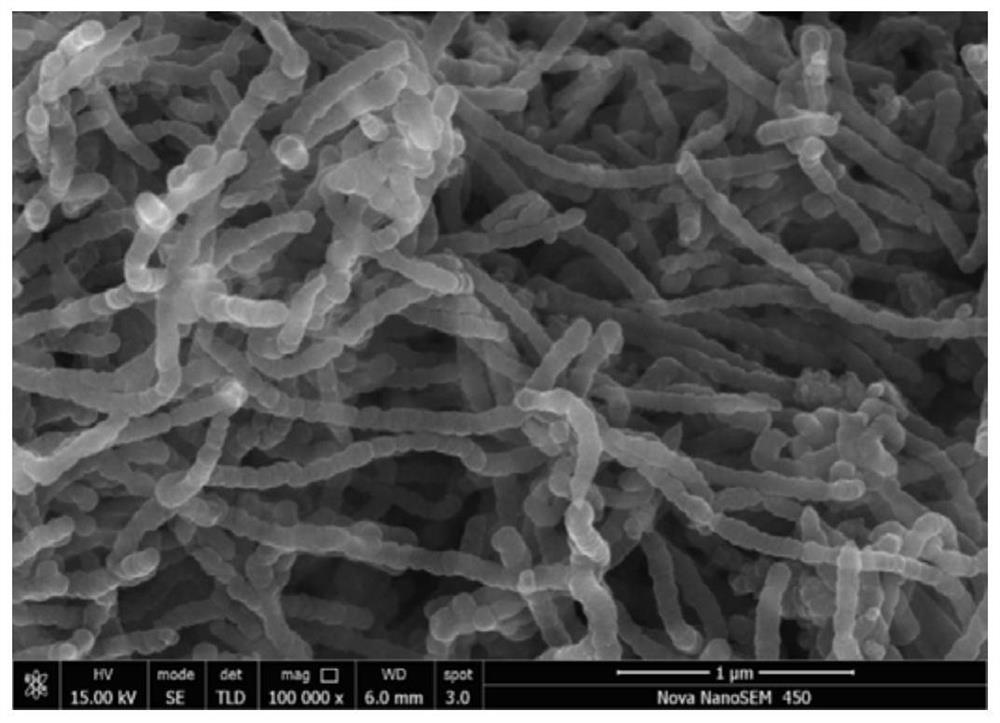

Embodiment 1

[0028] The preparation method of azacarbon nanotube sample 1 comprises the following steps:

[0029] Step 1: Weigh 20 mg of pyrrole and dissolve it in 15 mL of methanol, add 192.8 mg of induction reagent polyethylene glycol octylphenyl ether (the molar ratio of induction reagent to pyrrole monomer is 1:1), stir well to dissolve, add 15 mL The 1M ferric chloride solution of the oxidizing agent was stirred rapidly for 4 hours, followed by filtering, washing with ethanol, washing with water, and vacuum drying to obtain polypyrrole nanotubes.

[0030] Step 2: Place the polypyrrole nanotubes in a tube furnace, protect them with argon, raise the temperature from room temperature to 500°C at 10°C / min and keep it warm for 3 hours to obtain azacarbon nanotubes, which are designated as sample 1.

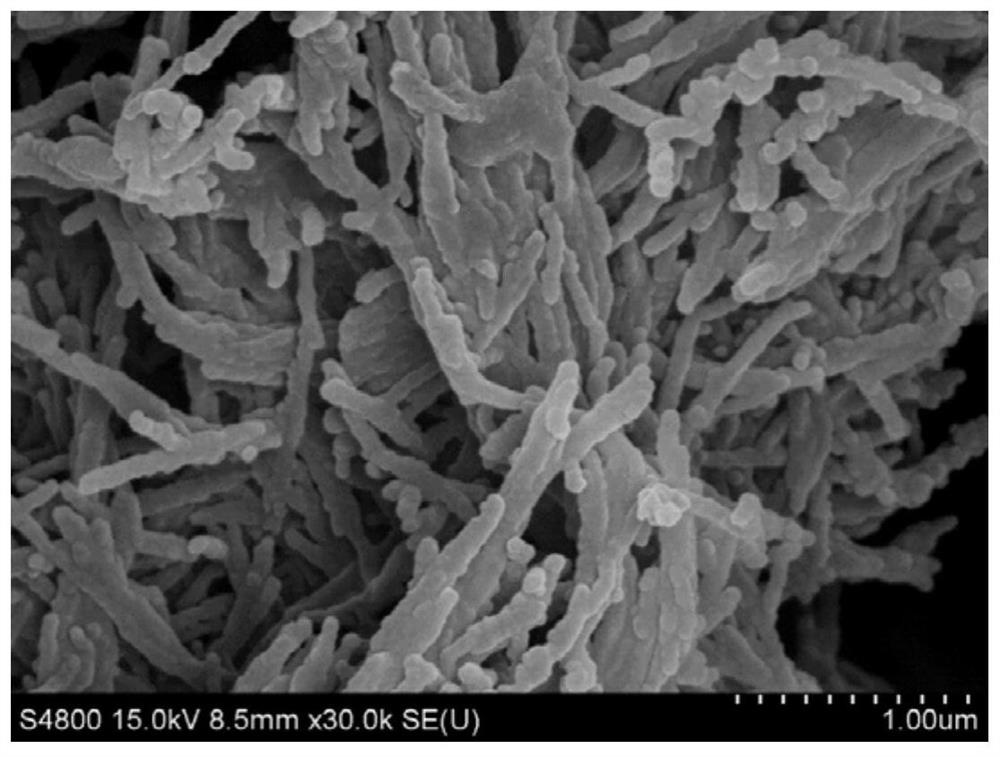

Embodiment 2

[0032] The preparation method of azacarbon nanotube sample 2 comprises the following steps:

[0033] Step 1: Weigh 20 mg of pyrrole and dissolve it in 15 mL of methanol, add 85.9 mg of induction reagent sodium dodecyl sulfate (the molar ratio of induction reagent to pyrrole monomer is 1:1), stir well to dissolve, add 15 mL of oxidant 1M chlorine The ferric chloride solution was stirred rapidly for 4 hours, followed by steps of filtration, ethanol washing, water washing, and vacuum drying to obtain polypyrrole nanotubes.

[0034] Step 2: Place the polypyrrole nanotubes in a tube furnace, protect them with argon, and raise them from room temperature to 500°C at 10°C / min and keep them warm for 3 hours to obtain azacarbon nanotubes, which are designated as sample 2.

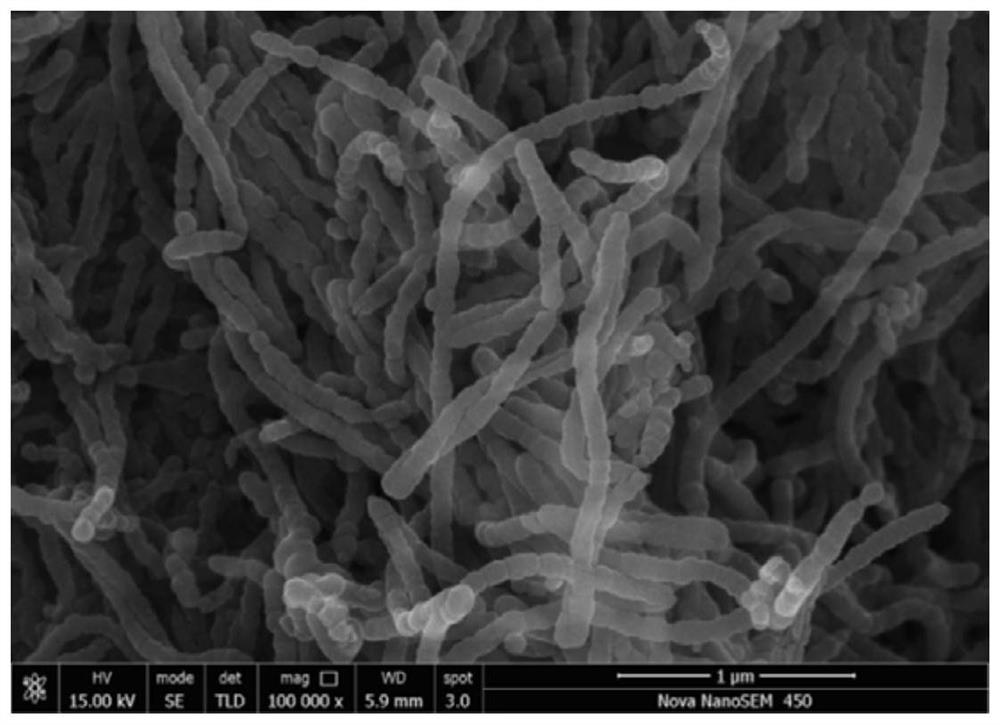

Embodiment 3

[0036] The preparation method of azacarbon nanotube sample 3 comprises the following steps:

[0037] Step 1: Weigh 100 mg of pyrrole and dissolve it in 30 mL of methanol, add 96.4 mg of induction reagent polyethylene glycol octylphenyl ether (the molar ratio of induction reagent to pyrrole monomer is 1:10), stir well to dissolve, add 15 mL The 1M ferric chloride solution of the oxidizing agent was stirred rapidly for 4 hours, followed by filtering, washing with ethanol, washing with water, and vacuum drying to obtain polypyrrole nanotubes.

[0038] Step 2: Place the polypyrrole nanotubes obtained in step 1 in a tube furnace, protect them with argon, raise them from room temperature to 500°C at 10°C / min and keep them warm for 3 hours to obtain azacarbon nanotubes, denoted as Sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption frequency | aaaaa | aaaaa |

| absorption frequency | aaaaa | aaaaa |

| absorption frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com