A two-step preparation method of high-performance conductive pressure-sensitive adhesive tape

A technology of pressure-sensitive adhesive tape and pressure-sensitive adhesive, which is applied in the direction of conductive coating, conductive adhesive, adhesive, etc., and can solve the problem of small adsorption force between the conductive paste layer and the substrate, poor mutual penetration and binding, difficult high conductivity performance, etc. problem, to achieve the effect of improved electrical conductivity, high adhesive performance, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] 1. Preparation of conductive carbon paste: Accurately weigh a certain amount of dissolved polymer resin solution, add an appropriate amount of additives, curing agent and organic solvent, fully stir and disperse, and then add a certain amount of carbon black (particle size is 30 ~300nm) and graphite (particle size 3~25μm), high-speed stirring to disperse into a slurry, using a three-roller to grind the resulting slurry to a fineness of 5μm and a viscosity of 12000mpa·s to obtain a conductive carbon paste;

[0040] 2. Preparation of pressure-sensitive adhesive: Accurately weigh a certain amount of polyacrylic acid resin solution, add leveling agent and organic solvent, fully stir and disperse, then add a certain quality of carbon black (particle size is 30-300nm) and graphite ( The particle size is 3-25μm), high-speed stirring and dispersing into a slurry, and the obtained slurry is ground by a three-roller machine, and the measured fineness is 5-10μm, and the viscosity i...

Embodiment 1

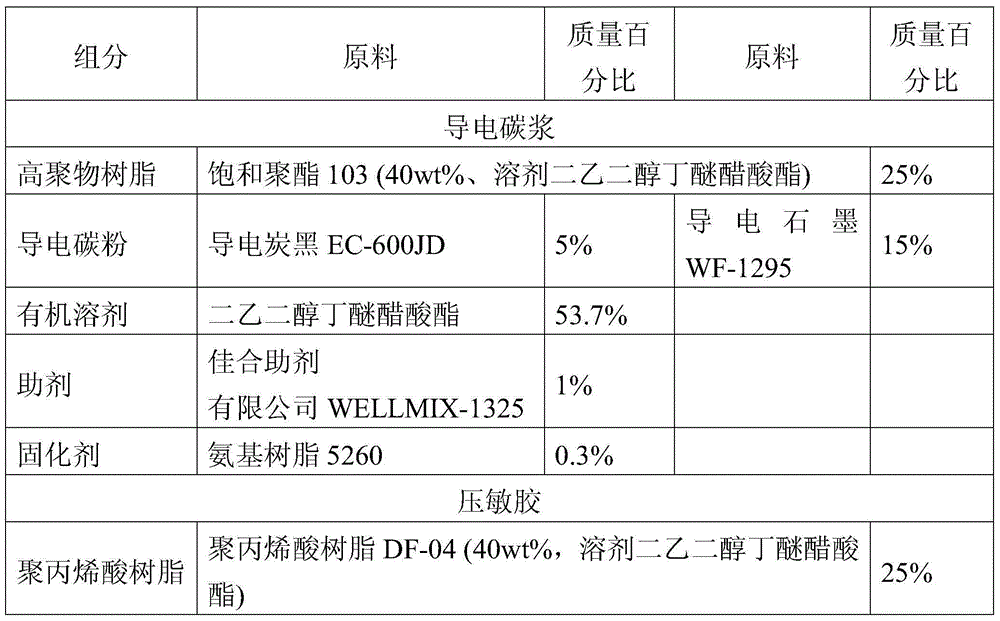

[0044] The mass percentages of the raw materials for preparing conductive carbon paste and pressure-sensitive adhesive are shown in Table 1. The high polymer resins and polyacrylic resins mentioned in Tables 1 to 4 need to be used as solutions, and the mass percentages indicated in the tables are the amounts of pure high polymer resins and polyacrylic resins, excluding those used when making solutions. the amount of solvent used.

[0045] Table 1

[0046]

[0047]

[0048] Film-making method: The film-making method of the conductive carbon paste film layer is the screen printing method, and it is dried at 110°C for 10 minutes; the film-making method of the pressure-sensitive adhesive layer is the roll coating method, and it is dried at 110°C for 5 minutes.

Embodiment 2

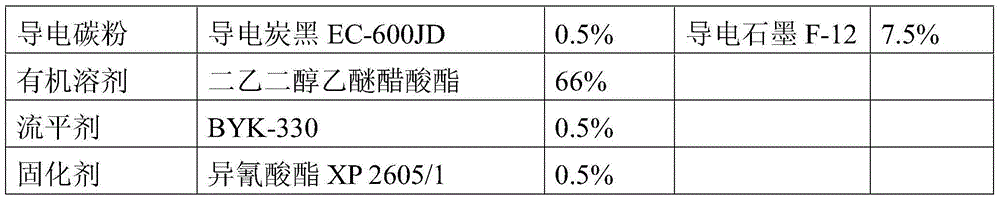

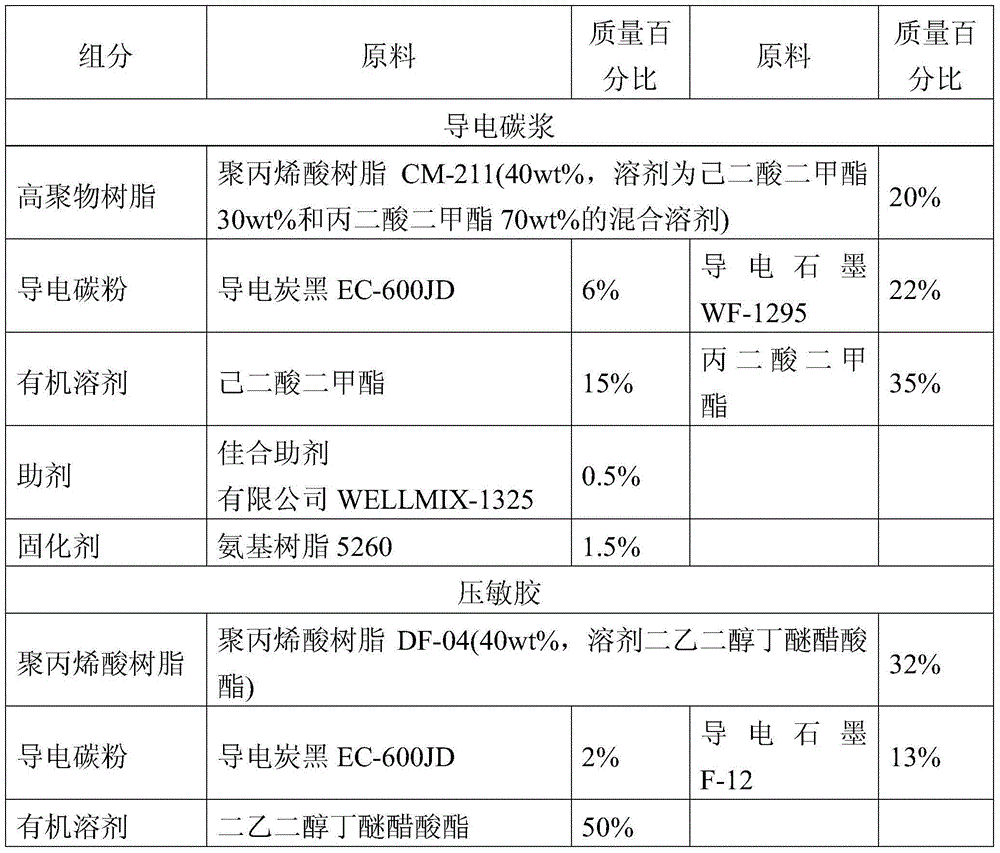

[0050] The mass percentages of the raw materials for preparing conductive carbon paste and pressure-sensitive adhesive are shown in Table 2.

[0051] Table 2

[0052]

[0053]

[0054] Film-making method: The film-making method of the conductive carbon paste film layer is the screen printing method, which is dried at 120°C for 8 minutes; the film-making method of the pressure-sensitive adhesive layer is the screen printing method, which is dried at 120°C for 1 minute.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com