UV (ultraviolet) barrier optical adhesive and preparation method thereof

An adhesive and optical technology, applied in the field of materials, can solve the problems of easy aging of optical devices, affecting the service life and visual effect, unable to block ultraviolet rays, etc., and achieve the effect of solving easy aging, reducing transmittance and high peel strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

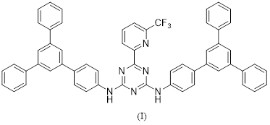

[0034] The preparation of embodiment 1 formula (I) compound

[0035]

[0036] Dissolve 2,4-dichloro-6-(6-(trifluoromethyl)pyridin-2-yl)-1,3,5-triazine (70g, 237.2mmol) in 300mL tetrahydrofuran, add 3', 5'-diphenylbiphenyl-4-amine (83.9g, 261mmol), sodium carbonate (76g, 712mmol), heated to reflux for 72h. The reaction solution was filtered, and the filtrate was purified by column chromatography to obtain the title compound. MS m / z (ESI): 865.2[M+H] + .

Embodiment 2

[0038] The UV blocking optical adhesive, the raw materials according to parts by weight include:

[0039] 60 parts of polyurethane acrylate; 40 parts of the compound shown in formula (I) prepared in Example 1; 10 parts of titanium dioxide; 10 parts of 6-hexanediol diacrylate; 5 parts of 1-hydroxycyclohexyl phenyl ketone; 8 parts of pentaerythritol tetraphenylpropionate.

[0040] Weigh polyurethane acrylate, the compound represented by formula (I) prepared in Example 1, titanium dioxide, and 6-hexanediol diacrylate respectively according to the above weight percentages and add them to the reaction kettle, and stir at room temperature for 2 hours; according to the above Weigh 1-hydroxycyclohexyl phenyl ketone and pentaerythritol tetraphenylpropionate in percentage by weight, and stir for 5 hours until they are evenly mixed; use a high-speed centrifugal defoamer to defoam again, with a defoaming rate of 2500r / min. The time is 3-5 minutes, and the target optical adhesive is obtai...

Embodiment 3

[0042] The UV blocking optical adhesive, the raw materials according to parts by weight include:

[0043] 30 parts of polyurethane acrylate; 30 parts of the compound shown in formula (I) prepared in Example 1; 20 parts of titanium dioxide; 10 parts of 6-hexanediol diacrylate; 5 parts of 1-hydroxycyclohexyl phenyl ketone; 5 parts of pentaerythritol tetraphenylpropionate.

[0044] Weigh polyurethane acrylate, the compound represented by formula (I) prepared in Example 1, titanium dioxide, and 6-hexanediol diacrylate respectively according to the above weight percentages and add them to the reaction kettle, and stir at room temperature for 2 hours; according to the above Weigh 1-hydroxycyclohexyl phenyl ketone and pentaerythritol tetraphenylpropionate in percentage by weight, and stir for 5 hours until they are evenly mixed; use a high-speed centrifugal defoamer to defoam again, with a defoaming rate of 2300r / min. The time is 3-5 minutes, and the target optical adhesive is obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com