Lightweight, heat-insulating, anti-seepage and pressure-bearing door and window frame joint sealant as well as preparation method, use method and application thereof

A door and window frame and caulking glue technology, applied in the direction of frame fixing, etc., can solve the problems of water seepage, poor load bearing, and poor bonding of door and window frames, and achieve the effects of increasing adsorption sites, reducing strength, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

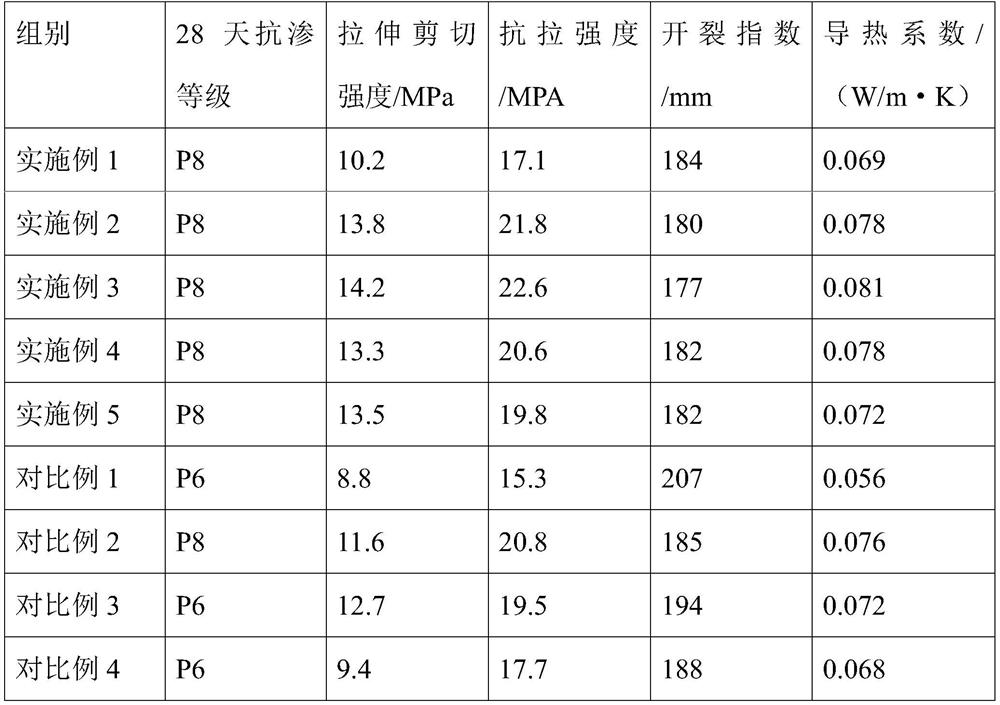

Examples

Embodiment 1

[0029] A light-weight, heat-preserving, anti-seepage, and pressure-bearing sealant for door and window frames, including the following raw materials in parts by mass: 20 parts of cement, 25 parts of quartz powder, 10 parts of heavy calcium, 1 part of kaolin, and 1 part of polymer glue powder, 0.5 parts of polystyrene particles, 0.1 parts of powder defoamer, 4 parts of composite fibers, 0.1 part of water-retaining thickener, 0.05 parts of starch ether and 0.3 parts of melamine-based water reducer; wherein, the composite fibers are polypropylene fibers, Steel nanofiber and carbon fiber; water retention thickener is puffed rice husk. Wherein, the cement is aluminate cement and Portland cement with a mass ratio of 1:1. The composite fiber is polypropylene fiber, steel nanofiber and carbon fiber with a mass ratio of 2:2:1.

[0030] Wherein, the preparation method of described puffed rice husk is:

[0031] 1) Collect rice husks for grinding treatment, add water to infiltrate the r...

Embodiment 2

[0038] A light-weight, heat-preserving, anti-seepage, and pressure-bearing sealant for door and window frames, including the following raw materials in parts by mass: 50 parts of cement, 40 parts of quartz powder, 15 parts of heavy calcium, 5 parts of kaolin, and 5 parts of polymer glue Powder, 1.5 parts of polystyrene particles, 0.5 parts of powder defoamer, 10 parts of composite fiber, 0.5 part of water-retaining thickener, 0.1 part of starch ether and 0.5 part of polycarboxylate superplasticizer; wherein, the composite fiber is polypropylene fiber, Steel nanofiber and carbon fiber; water retention thickener is puffed rice husk. Wherein, the cement is aluminate cement and Portland cement with a mass ratio of 1:2. The composite fibers are polypropylene fibers, steel nanofibers and carbon fibers with a mass ratio of 3):3:1.

[0039] Wherein, the preparation method of puffed rice husk and the preparation method of door and window frame gap filler are the same as in Example 1. ...

Embodiment 3

[0041]A light-weight, heat-preserving, anti-seepage, and pressure-bearing sealant for door and window frames, including the following raw materials in parts by mass: 45 parts of cement, 30 parts of quartz powder, 13 parts of heavy calcium, 3 parts of kaolin, and 3 parts of polymer glue Powder, 1 part of polyphenylene granules, 0.4 part of powder defoamer, 6 parts of composite fiber, 0.3 part of water-retaining thickener, 0.06 part of starch ether and 0.4 part of polycarboxylate superplasticizer; wherein, the composite fiber is polypropylene fiber, Steel nanofiber and carbon fiber; water retention thickener is puffed rice husk. Wherein, the cement is aluminate cement and Portland cement with a mass ratio of 1:1.5. The composite fiber is polypropylene fiber, steel nanofiber and carbon fiber with a mass ratio of 2:3:1.

[0042] Wherein, the preparation method of puffed rice husk and the preparation method of door and window frame gap filler are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com