Automobile hub grinding system and method based on cooperation of double industrial robots

A technology for automobile hubs and robots, which is applied to the parts of grinding machine tools, the control of workpiece feed movement, and the machine tools designed for grinding the rotating surface of workpieces. problems, to achieve the effect of improving processing efficiency and processing accuracy, flexible grinding and processing operations, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

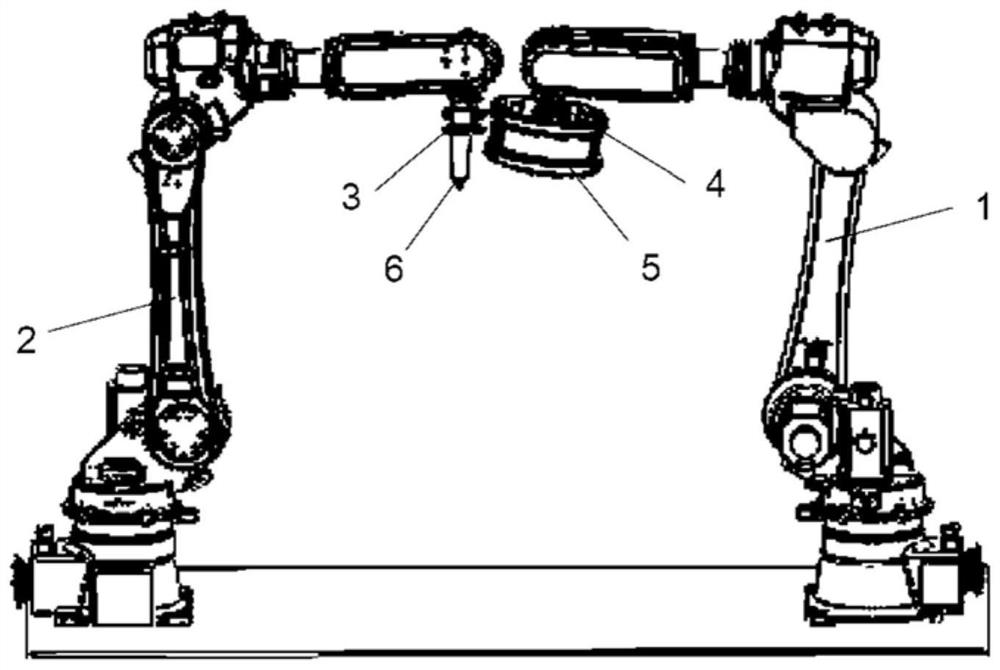

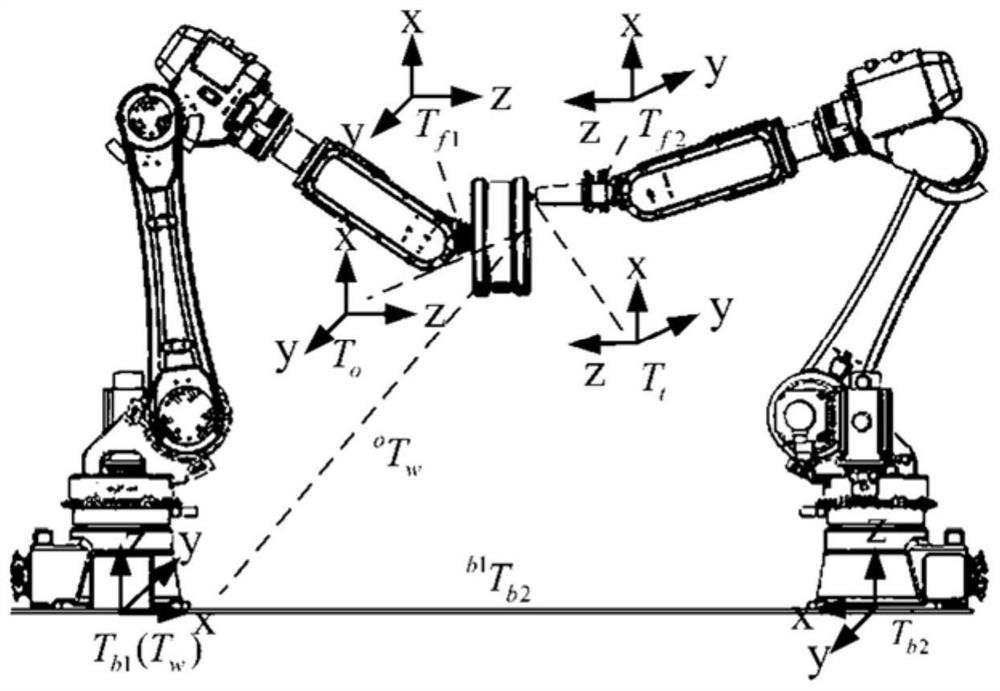

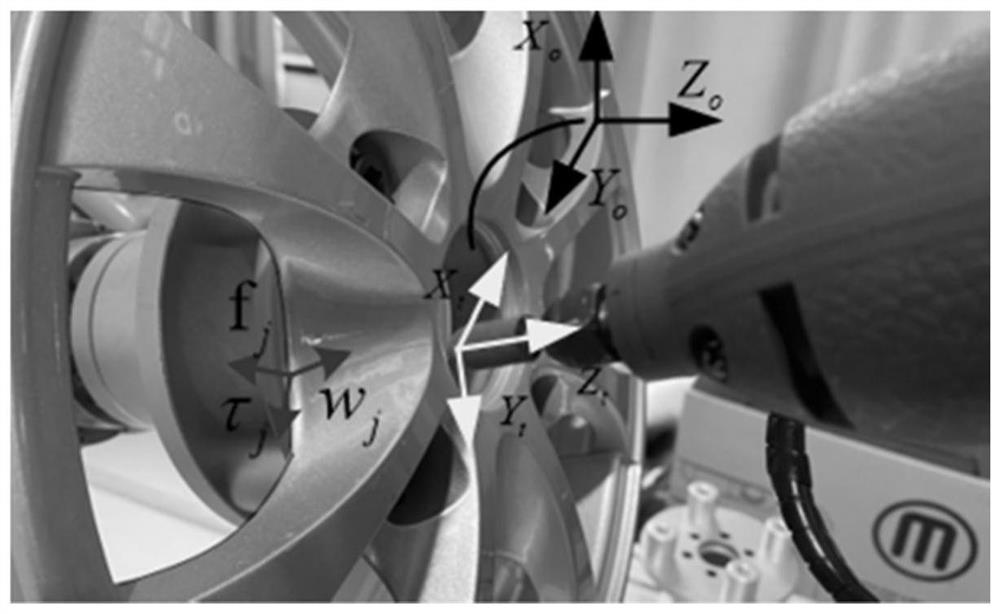

[0038] Such as figure 1 As shown, a car hub grinding system based on the cooperation of dual industrial robots includes a first mechanical arm 1 and a second mechanical arm 2, and the end of the first mechanical arm 1 is connected and installed with a wheel hub 4 to be polished through a first electric spindle 5, The end of the second mechanical arm 2 is connected with the processing tool 3 through the second electric spindle 6, and the first mechanical arm 1 and the second mechanical arm 2 respectively control the processing of the hub 4 according to the corresponding processing trajectory and instructions set. position, the working position and processing force of the processing tool 3.

[0039] Wherein, the first robotic arm 1 and the second robotic arm 2 are respectively connected to the same controller, and the control program corresponding to the first robotic arm 1 and the second robotic arm 2 is stored in the controller.

[0040] In practical applications, the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com