Method for preparing copper-silver alloy hydrogen evolution catalyst through friction stir processing

A copper-silver alloy and friction stir technology, which is applied in metal processing equipment, non-precious metal oxide coatings, manufacturing tools, etc., can solve the problems of low hydrogen evolution overpotential, improve hydrogen evolution performance, save the coating process, and facilitate The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

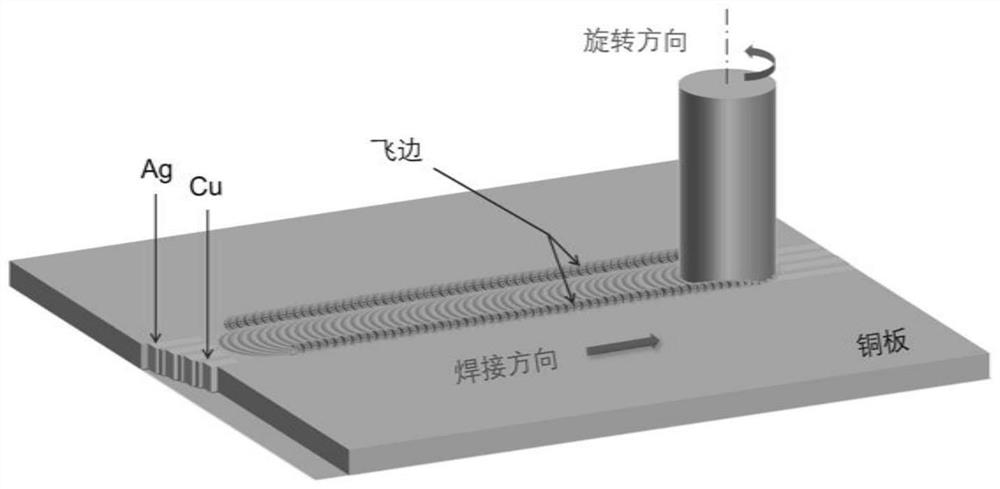

[0043] (1) Take bulk metal copper plates, copper flakes and silver flakes as raw materials; clean the surface of the raw materials;

[0044] (2) Fix the metal copper plate and silver sheet on the workbench of the friction stir welding machine with a clamp, and sandwich a piece of silver (length 20mm × width 1mm × height 5mm) between the two copper plates;

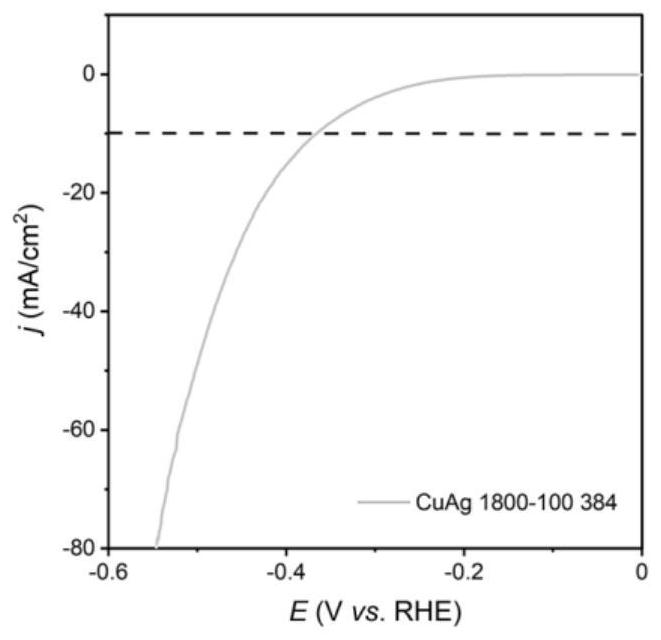

[0045] (3) Use a stirring head with a shoulder; at the beginning of processing, the stirring head is aligned with the copper and silver sheet, adjust the stirring head to press down until the stirring needle is completely submerged in the processed metal, the distance between the shoulder and the surface of the copper plate is less than 2mm, and the processing parameters are set as 1800rpm--100mm / min, let the stirring head automatically rotate along one end of the copper-silver sheet and advance to the other end to mix once;

[0046] (4) Sampling: The stirring head still starts processing from the starting position of the l...

example 2

[0049] (1) Take bulk metal copper plates, copper flakes and silver flakes as raw materials; clean the surface of the raw materials;

[0050] (2) Fix the metal copper plate and silver sheet on the workbench of the friction stir welding machine with a clamp, and sandwich a piece of silver (length 20mm × width 1mm × height 5mm) between the two copper plates;

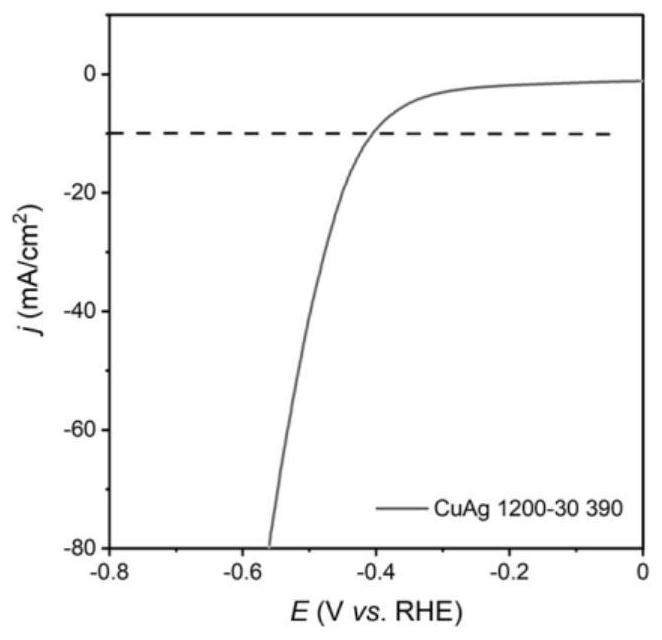

[0051] (3) Use a stirring head with a shoulder; at the beginning of processing, the stirring head is aligned with the copper and silver sheet, adjust the stirring head to press down until the stirring needle is completely submerged in the processed metal, the distance between the shoulder and the surface of the copper plate is less than 2mm, and the processing parameters are set as 1200rpm--30mm / min, let the stirring head automatically rotate along one end of the copper and silver sheet to the other end to mix once;

[0052] (4) Sampling: The stirring head still starts processing from the starting position of the last proce...

example 3

[0055] (1) Take bulk metal copper plates, copper flakes and silver flakes as raw materials; clean the surface of the raw materials;

[0056] (2) Fix the metal copper plate and silver sheet on the workbench of the friction stir welding machine with a clamp, and sandwich a piece of silver (length 20mm × width 1mm × height 5mm) between the two copper plates;

[0057] (3) Use a stirring head with a shoulder; at the beginning of processing, the stirring head is aligned with the copper and silver sheet, adjust the stirring head to press down until the stirring needle is completely submerged in the processed metal, the distance between the shoulder and the surface of the copper plate is less than 2mm, and the processing parameters are set as 1200rpm--200mm / min, let the stirring head automatically rotate along one end of the copper and silver sheet to the other end for mixing once;

[0058] (4) Sampling: The stirring head still starts processing from the starting position of the last ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com