Manufacturing method of liquid crystal display panel, liquid crystal display panel

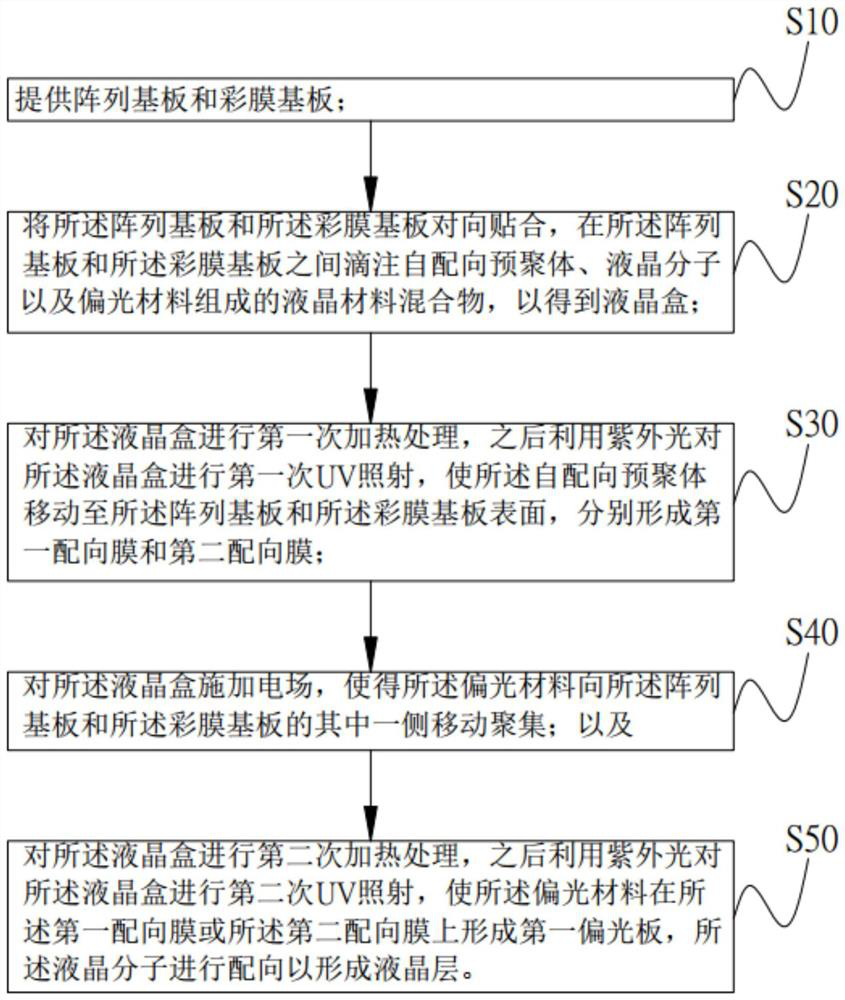

A technology of liquid crystal display panel and manufacturing method, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of the stability of easily damaged quantum dot materials and the complex coating process of alignment film, so as to save coating process and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

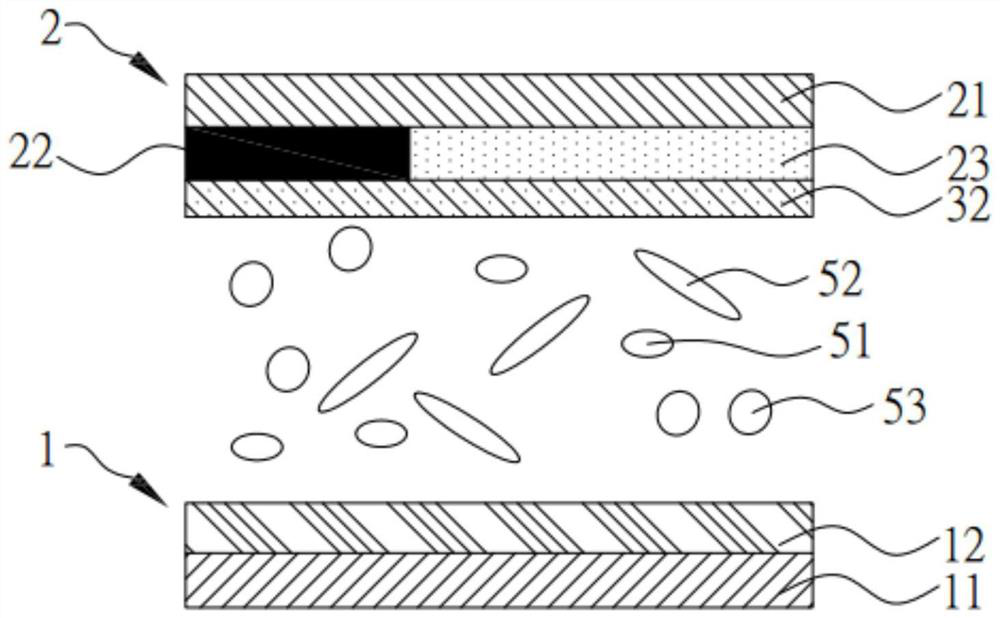

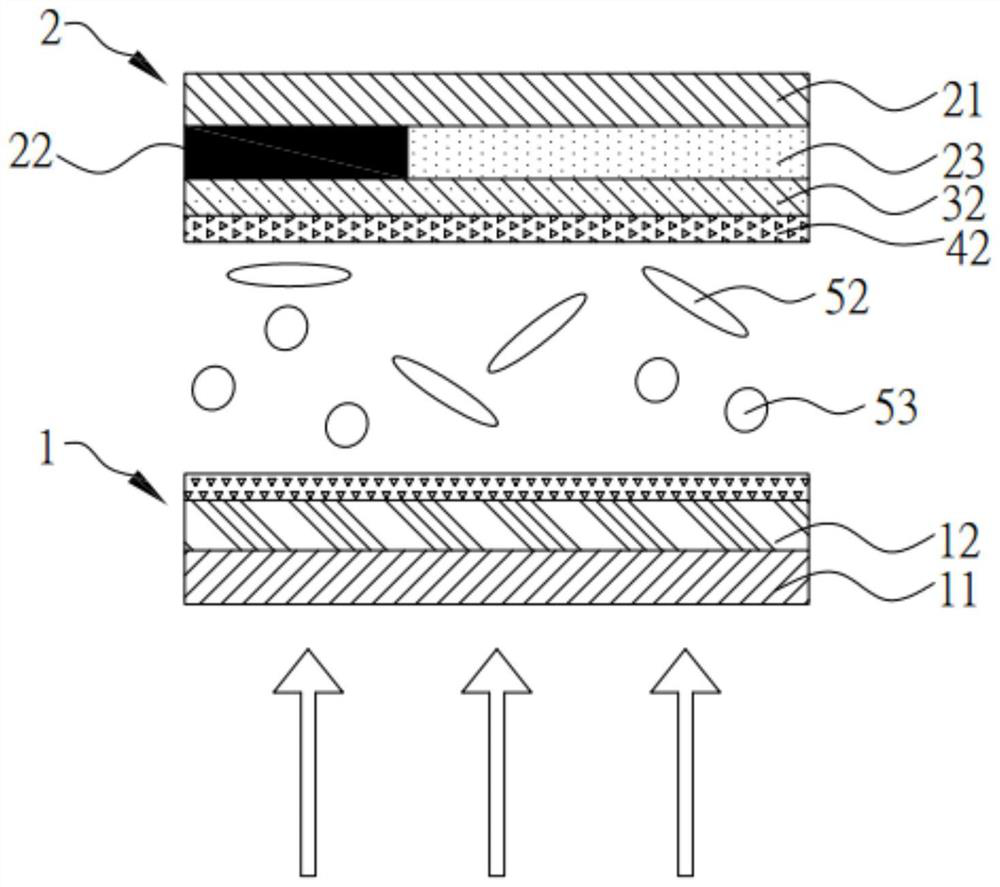

[0062] Such as Figure 6A , Figure 6B As shown, the liquid crystal display panel provided by the embodiment of the present disclosure is manufactured by the manufacturing method in the above embodiment, and the liquid crystal display panel includes an array substrate 1, a color filter substrate 2 disposed opposite to the array substrate 1, and a The liquid crystal layer, the first alignment film 41 , the second alignment film 42 and the first polarizer 31 between the array substrate 1 and the color filter substrate 2 .

[0063] Specifically, the array substrate 1 includes a first base substrate 11 , a thin film transistor array layer 12 and a first electrode layer disposed on the first base substrate 11 . The color filter substrate 2 includes a second base substrate 21, a black matrix 22, and a color-resist layer 23. Further, the material of the color-resist layer 23 may be a quantum dot material, which displays different colors when excited by light. The color filter subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com