A method for preparing silicon carbon negative electrode sheet by extrusion calendering and electrode sheet

A negative electrode, silicon carbon technology, applied in negative electrodes, electrode manufacturing, electrode extrusion, etc., can solve problems such as peeling and cracking, and achieve the effects of improving physical strength, reducing surface resistance, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

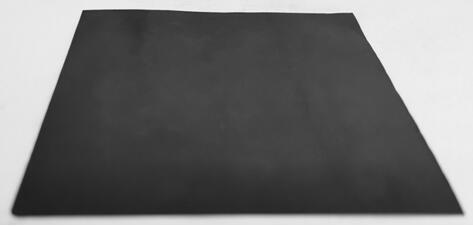

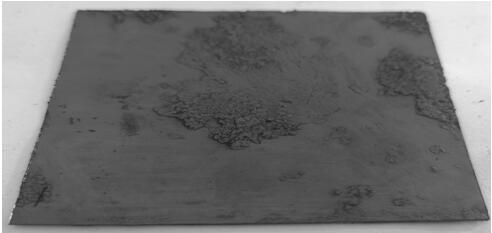

Image

Examples

Embodiment 1

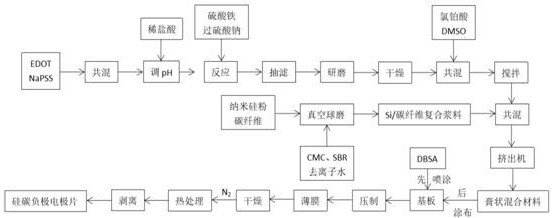

[0046] A method for preparing a silicon carbon negative electrode sheet by extrusion calendering, comprising the steps of:

[0047] Step 1. Add PEDOT:PSS (the conductivity of PEDOT:PSS is 400s / cm), chloroplatinic acid, and dimethyl sulfoxide into the mixing device in order of 10, 2, and 10 parts by weight, and stir evenly. 100r / min, stirring time is 40min, the modified PEDOT:PSS slurry is obtained;

[0048] Step 2: Mix nano-silica powder, carbon fiber (the length of carbon fiber is 0.1-5 mm, and the diameter is 1-20 μm), sodium carboxymethyl cellulose, styrene-butadiene rubber emulsion with a mass concentration of 30%, and deionized water in parts by weight Add 10, 80, 1, 1, and 100 into the mixing device in turn, stir evenly, the stirring speed is 50r / min, and the stirring time is 6h, and the silicon powder / carbon fiber composite slurry is obtained;

[0049] Step 3. Add PEDOT:PSS slurry and silicon powder / carbon fiber composite slurry to the mixing device in order of 10 and ...

Embodiment 2

[0054] A method for preparing a silicon carbon negative electrode sheet by extrusion calendering, comprising the steps of:

[0055] Step 1. Add PEDOT:PSS (the conductivity of PEDOT:PSS is 400s / cm), chloroplatinic acid, and dimethyl sulfoxide into the mixing device in order of 20, 3, and 20 parts by weight, and stir evenly. 200r / min, stirring time is 20min, the modified PEDOT:PSS slurry is obtained;

[0056] Step 2: Mix nano-silica powder, carbon fiber (the length of carbon fiber is 0.1-5 mm, and the diameter is 1-20 μm), sodium carboxymethyl cellulose, styrene-butadiene rubber emulsion with a mass concentration of 30%, and deionized water in parts by weight Add 15, 95, 2, 2, and 180 into the mixing device in turn, stir evenly, the stirring speed is 100 / min, and the stirring time is 3 hours, and the silicon powder / carbon fiber composite slurry is obtained;

[0057] Step 3. Add PEDOT:PSS slurry and silicon powder / carbon fiber composite slurry to the mixing device in order of 15...

Embodiment 3

[0062] A method for preparing a silicon carbon negative electrode sheet by extrusion calendering, comprising the steps of:

[0063] Step 1. Add PEDOT:PSS (the conductivity of PEDOT:PSS is 400s / cm), chloroplatinic acid, and dimethyl sulfoxide into the mixing device in order of 13, 2.5, and 13 parts by weight, and stir evenly. 120r / min, stirring time is 40min, the modified PEDOT:PSS slurry is obtained;

[0064] Step 2: Mix nano-silica powder, carbon fiber (the length of carbon fiber is 0.1-5 mm, and the diameter is 1-20 μm), sodium carboxymethyl cellulose, styrene-butadiene rubber emulsion with a mass concentration of 30%, and deionized water in parts by weight Add 12, 84, 1.5, 1.5, and 120 into the mixing device in turn, stir evenly, the stirring speed is 80r / min, and the stirring time is 4h, and the silicon powder / carbon fiber composite slurry is obtained;

[0065] Step 3. Add PEDOT:PSS slurry and silicon powder / carbon fiber composite slurry to the mixing device in order of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com