Method for carbon sequestration, emission reduction, weight loss and efficiency improvement of machine-harvested rice in coastal rice area of eastern Hebei province

A carbon emission reduction and rice area technology, applied in the field of weight loss and efficiency enhancement, carbon sequestration and emission reduction of machine-harvested rice in Jidong Binhai Rice Area, can solve the problem of low fertilizer utilization rate, adverse effects on farmland and atmospheric ecological environment, and greenhouse gas emissions. increase and other problems, to achieve the effect of protecting the ecological environment, promoting the process of resource utilization, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

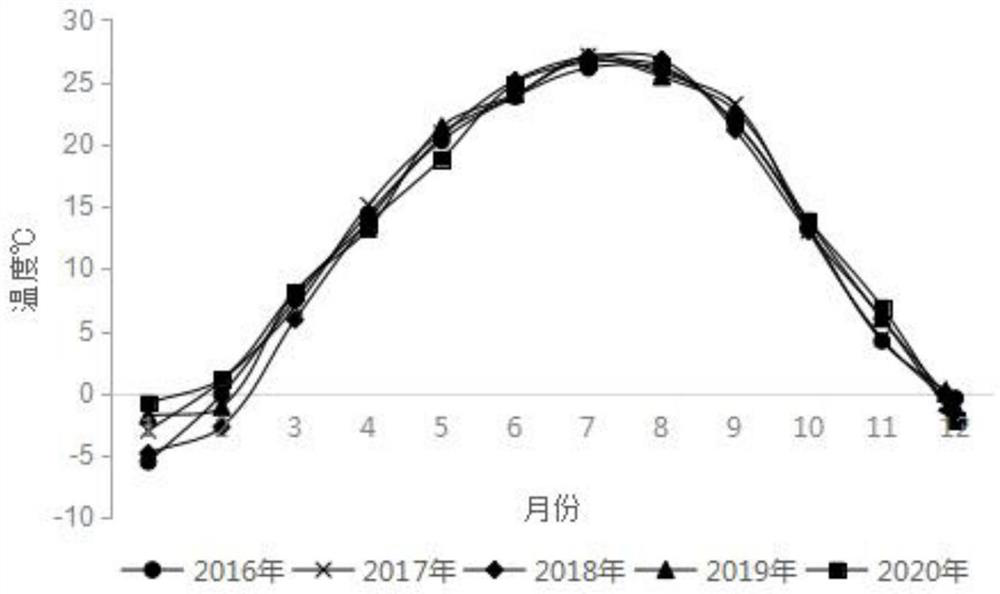

[0030] This experiment was carried out at the Binhai Agricultural Comprehensive Experimental Station of Hebei Academy of Agriculture and Forestry Sciences (39°17'40"N-118°27'22"E). The experimental station is 2.5 meters above sea level and belongs to the warm temperate zone semi-humid seasonal offshore continental type in the eastern monsoon region. Climate, the annual average temperature is 11.4°C, and the annual precipitation is 635.9mm, concentrated in July-August. The rice variety tested was Bindao 18.

[0031] This example is a method for machine-harvested rice in the coastal rice region of Jidong to fix carbon, reduce emissions, lose weight and increase efficiency. The method is:

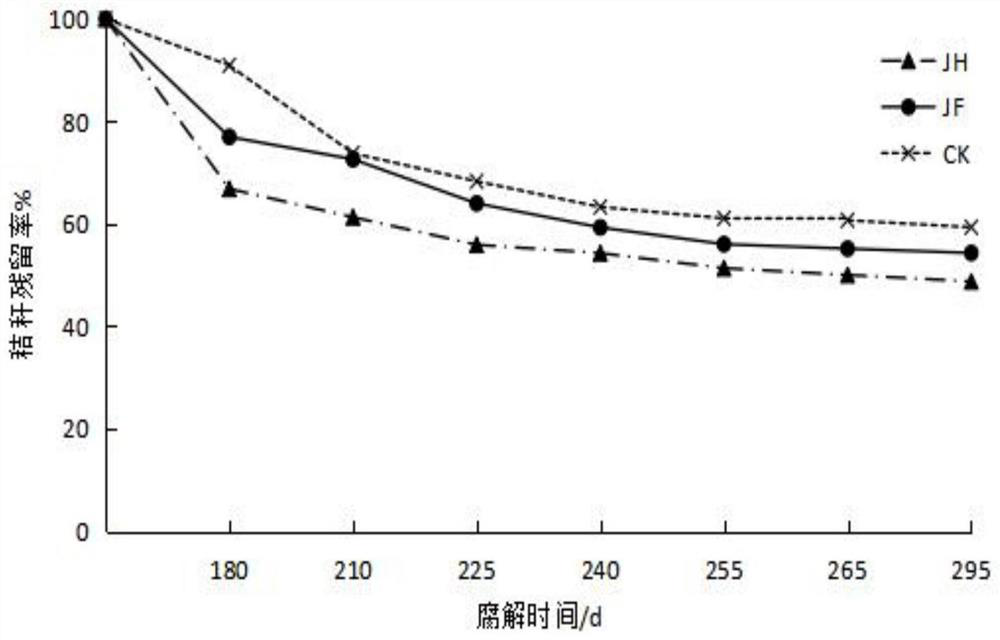

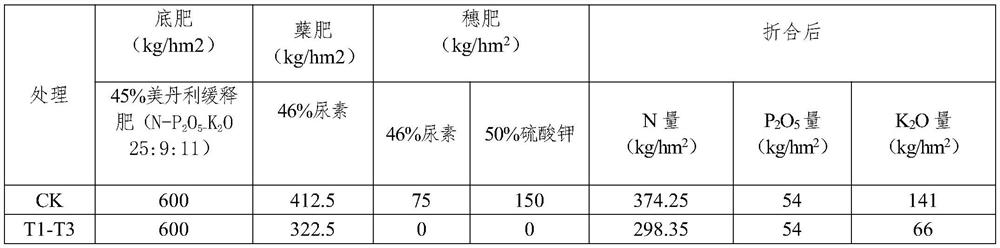

[0032] S1. Autumn rice harvesting and straw crushing and returning to the field: At the end of October of the first year (October 30, 2020), the rice was harvested with a harvester. The height of the rice stubble was 10cm. field, to obtain the returned straw, sprinkle the rice straw decompose...

Embodiment 2

[0053] This experiment will be carried out at the Fourth Farm in Caofeidian District, Tangshan City, Hebei Province from 2020 to 2021. The physical and chemical properties of the 0-20cm plow layer soil in the test site: the total salt content is 1.39g / kg, the pH value is 7.51, the organic matter is 18.56g / kg, and the available phosphorus is 20.13g / kg. The available potassium is 255.12mg / kg, and the available nitrogen is 78.81mg / kg.

[0054] This example is a method for machine-harvested rice in the coastal rice region of Jidong to fix carbon, reduce emissions, lose weight and increase efficiency. The method is:

[0055] S1. Autumn rice harvesting, straw crushing and returning to the field: In the first ten days of November of the first year (November 1, 2020), the rice is harvested with a harvester. The height of the rice stubble is 15cm. Return to the field to obtain the returned straw, sprinkle the rice straw decomposed microbial agent on the returned straw, and plow the ri...

Embodiment 3

[0068] This example is a test for the establishment of methods for machine-harvested rice carbon sequestration, emission reduction, weight loss and efficiency enhancement in the coastal rice area of eastern Jidong:

[0069] The research area is located in the first agricultural experiment field (N39° 16'31", E118°27'5.14") of Binhai Modern Agriculture Comprehensive Experimental Station, Caofeidian District, Tangshan City. Sufficient precipitation, concentrated precipitation, rain and heat at the same time, four seasons with distinct cold, warm, dry and wet climate characteristics. The annual average temperature is 11.4°C, the average evaporation is 1969mm, and the annual precipitation is 635.9mm, mainly concentrated in July-August. The soil type of the test site is paddy soil, the physical and chemical properties of the 0-20cm plow layer soil: total salt content is 1.26g / kg, pH value is 7.65, organic matter is 17.94g / kg, total nitrogen is 1.13g / kg, available phosphorus is 19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com