Preparation method of organic silicon-based RAFT (reversible addition-fragmentation chain transfer) reagent

An organosilicon and reagent technology, applied in the field of preparation of organosilicon-based RAFT reagents, can solve the problems of low introduction of organosilicon, poor dispersibility, volatile organic pollution, etc. The effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

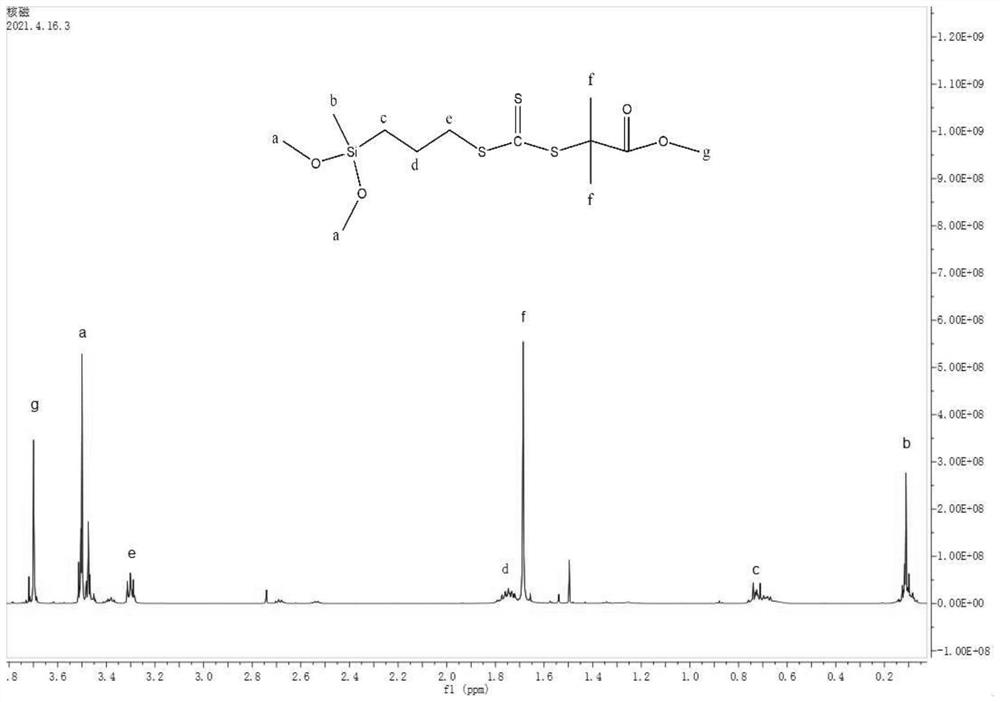

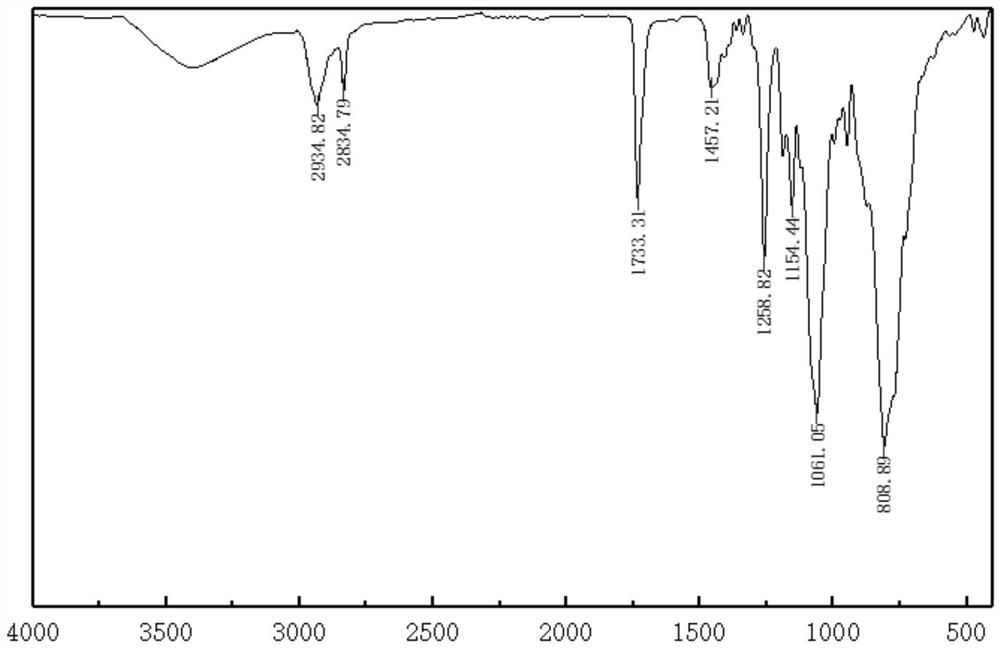

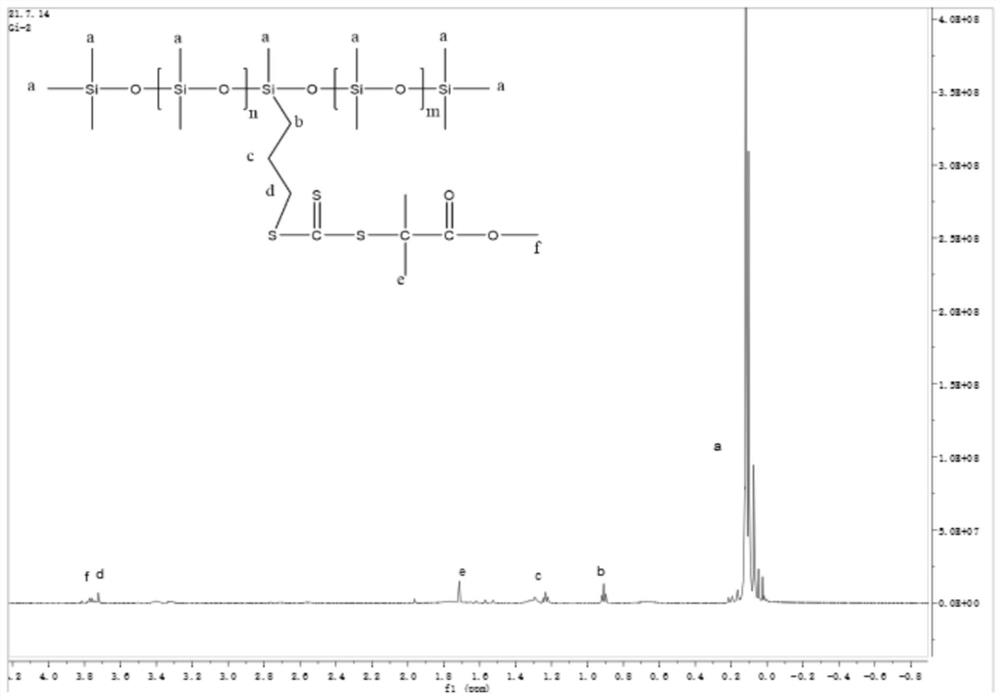

[0063] Add 7.2g of mercaptopropyldimethoxymethylsilane, 40g of dimethyl sulfoxide, and 6.2g of triethylamine into the reaction kettle, stir for 20 minutes at normal temperature and pressure at 400rpm, then add 8.2g of carbon disulfide, and Electric substitution reaction, the reaction time is 4 hours; after the reaction, add 6.5g of methyl dibromoisobutyrate, through the electrophilic substitution reaction for 14 hours, and then wash with water to remove the solvent under reduced pressure to obtain the RAFT reagent. Finally, add 1g of RAFT reagent, 9g of diethoxydimethoxysilane, 0.46g of hexamethyldisiloxane, 2g of concentrated hydrochloric acid, 6g of deionized water, and 20g of n-hexane into the reaction kettle, at 75°C and 400rpm After reacting for 6 hours, the acid water was removed by chromatography, and the solvent was distilled off under reduced pressure to obtain an organosilicon-based RAFT reagent.

Embodiment 2

[0065] Add 7.2g of mercaptopropyldimethoxymethylsilane, 40g of dimethyl sulfoxide, and 6.2g of triethylamine into the reaction kettle, stir for 20 minutes at normal temperature and pressure at 400rpm, then add 8.2g of carbon disulfide, and Electric substitution reaction, the reaction time is 4 hours; after the reaction, add 6.5g of methyl dibromoisobutyrate, through the electrophilic substitution reaction for 14 hours, and then wash with water to remove the solvent under reduced pressure to obtain the RAFT reagent. Finally, 1.185g of RAFT reagent, 15.81g of diethoxydimethoxysilane, 0.54g of hexamethyldisiloxane, 2g of concentrated hydrochloric acid, 6g of deionized water, and 25g of n-hexane were added to the reaction kettle, at 70°C and 400rpm The reaction was carried out under the conditions for 5 hours, the acid water was removed by chromatography, and the solvent was distilled off under reduced pressure to obtain an organosilicon-based RAFT reagent.

Embodiment 3

[0067] Add 7.2g of mercaptopropyldimethoxymethylsilane, 40g of dimethyl sulfoxide, and 6.2g of triethylamine into the reaction kettle, stir for 20 minutes at normal temperature and pressure at 400rpm, then add 8.2g of carbon disulfide, and Electric substitution reaction, the reaction time is 4 hours; after the reaction, add 6.5g of methyl dibromoisobutyrate, through the electrophilic substitution reaction for 14 hours, and then wash with water to remove the solvent under reduced pressure to obtain the RAFT reagent. Finally, 2.37g of RAFT reagent, 11.85g of diethoxydimethoxysilane, 1.08g of hexamethyldisiloxane, 2g of concentrated hydrochloric acid, 6g of deionized water, and 25g of n-hexane were added to the reaction kettle, at 70°C and 400rpm The reaction was carried out under the conditions for 5 hours, the acid water was removed by chromatography, and the solvent was distilled off under reduced pressure to obtain an organosilicon-based RAFT reagent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com