High-temperature-resistant light-weight high-strength porous ceramic and preparation method thereof

A technology of porous ceramics and high temperature resistance, which is applied in the field of lightweight and high-strength porous ceramics and its preparation. It can solve the problems of excessive porous size distribution range, insufficient stability, and low reliability, and achieve high defect tolerance and short preparation cycle. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The described high-temperature-resistant, light-weight, high-strength porous ceramic and its preparation method comprise the following steps:

[0038] Using ceramic nanowire airgel as raw material, through chemical vapor infiltration (or chemical vapor deposition, CVD), a layer of silicon carbide can be deposited on the surface of ceramic nanowires to become ceramic nanofibers. Ceramic nanowires in physical contact can be joined by deposited SiC to form fixed SiC nodes.

[0039] CVD process: At a temperature of 1000°C to 1300°C, hydrogen and argon are introduced into the CVD furnace (or called a CVI furnace), the gas flow rate of hydrogen is 20ml / min to 600ml / min, and argon is the diluent gas , the ventilation rate of argon gas is 20ml / min~600ml / min, and the precursor is trichloromethylsilane (CH3Cl3Si) gasified by vacuum gasification or bubbling gasification, and then passed into the furnace to control the precursor The flow rate is 20ml / min~600ml / min, and the tempera...

Embodiment 1

[0041] The present embodiment has prepared the density is 0.1g / cm 3 The high-temperature-resistant light-weight and high-strength porous ceramics, the specific steps are as follows:

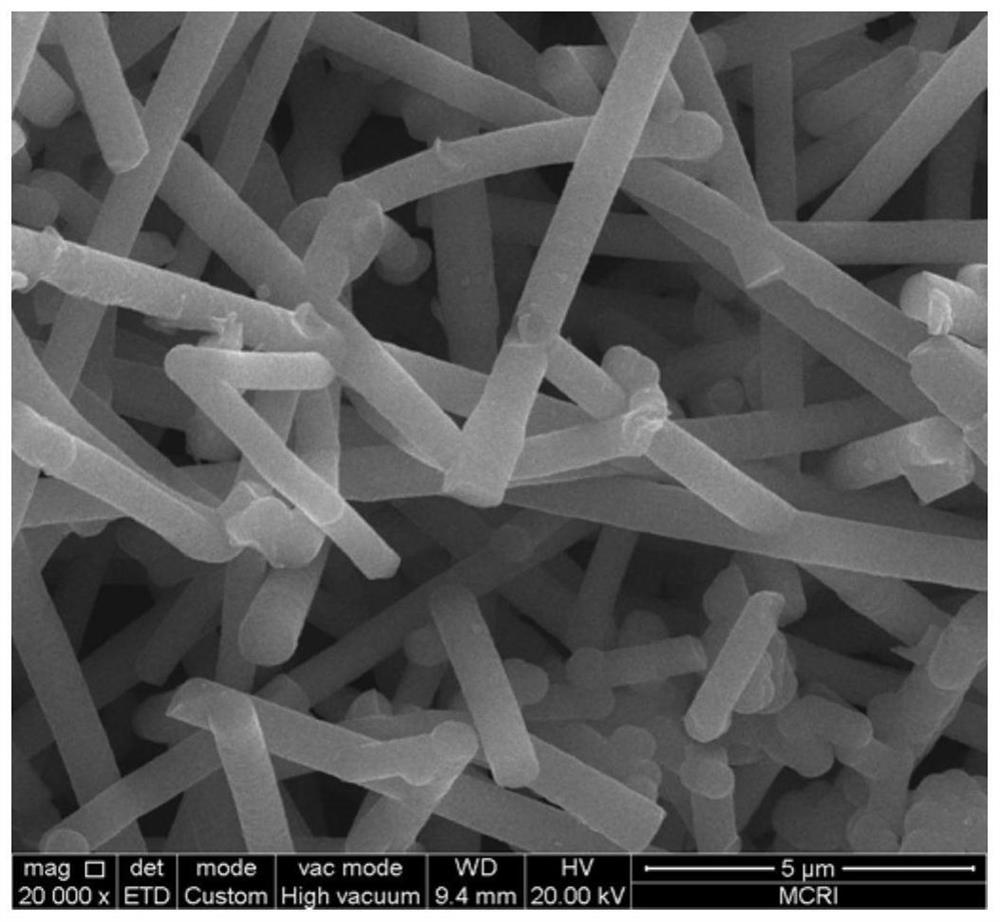

[0042] 10mg / cm2 prepared by the method disclosed in Chinese patent CN109627006A 3 The silicon carbide nanowire airgel is used as raw material, which is placed in a CVD deposition furnace, and hydrogen and argon are introduced into the furnace at a temperature of 1000 ° C, and trichloromethylsilane is Pass it into the furnace so that the flow of trichloromethylsilane into the furnace is maintained at 20ml / min, continue to ventilate and keep warm for 12 hours, pyrolyze SiC on the surface of silicon carbide nanowires, increase the diameter of the nanowires and make them contact each other The nanowires form a SiC node at the contact; the hydrogen ventilation rate is 100ml / min; the argon ventilation rate is 100ml / min;

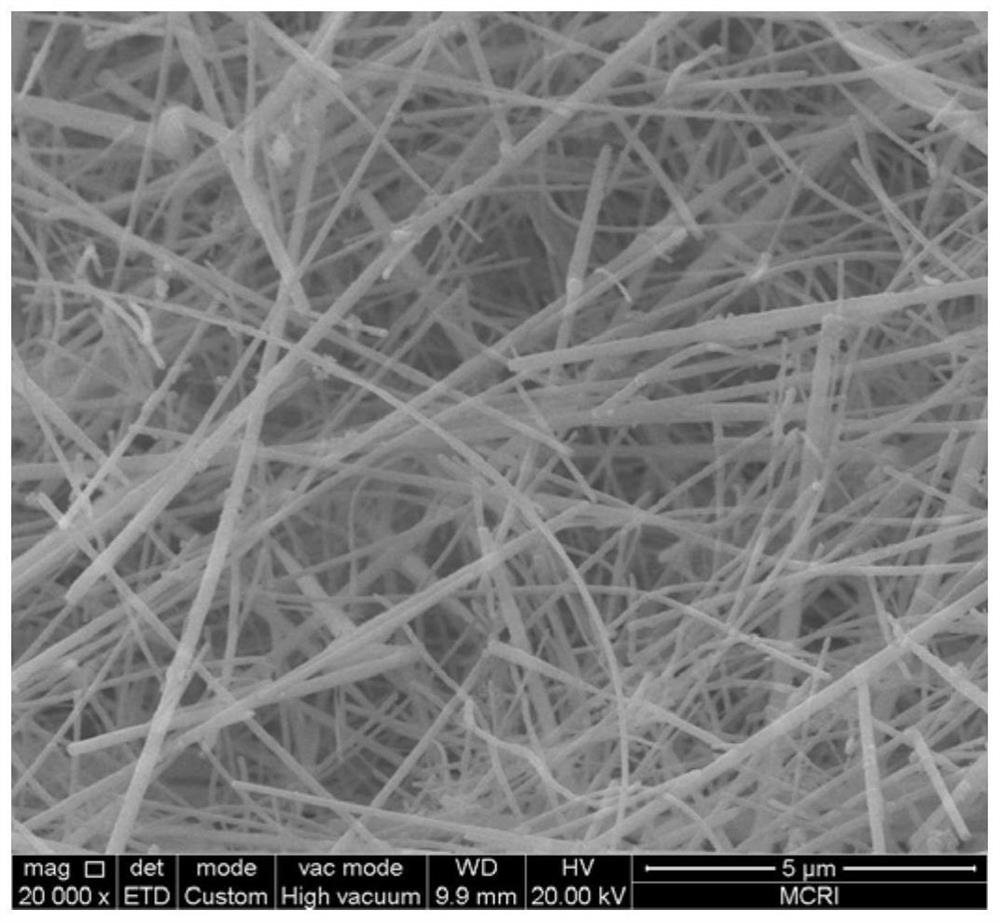

[0043] figure 1 Be the SEM picture of the silicon carbide nanowire airgel raw ...

Embodiment 2

[0045] The present embodiment has prepared the density is 0.3g / cm 3 The high-temperature-resistant light-weight and high-strength porous ceramics, the specific steps are as follows:

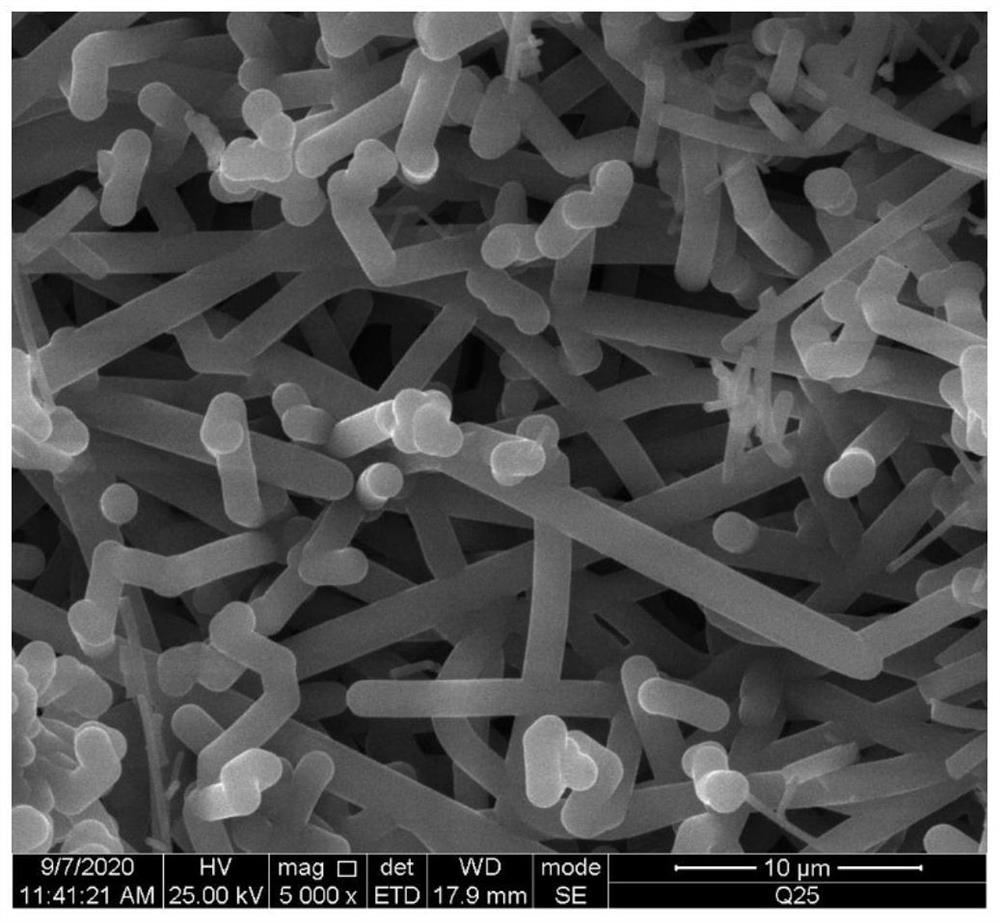

[0046] 10mg / cm2 prepared by the method disclosed in Chinese patent CN109627006A 3 SiC nanowire airgel was used as raw material, hydrogen and argon were introduced into the furnace at a temperature of 1100°C, and trichloromethylsilane (CH 3 Cl 3 Si) into the furnace, continue to ventilate and keep warm for 30h, generate SiC by pyrolysis on the surface of ceramic nanowires, and make the nanowires in contact with each other form SiC nodes at the contact points while increasing the diameter of the nanowires; the hydrogen gas ventilation rate Be 150ml / min; The argon ventilation rate is 150ml / min;

[0047] The resulting high-temperature-resistant, light-weight, high-strength porous ceramics have a volume density of 0.3 g / cm 3 , the porosity is 90.6%, and the compressive strength is 4.8MPa. When the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com