Large-tonnage vibration exciter

A vibration exciter and large tonnage technology, applied in the direction of vibrating fluid, portable lifting device, gear transmission device, etc., can solve the problems of high difficulty in processing eccentric wheels, limited service life, and high temperature rise of the box, so as to save the need for coordination Effect of installation process, cost saving and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

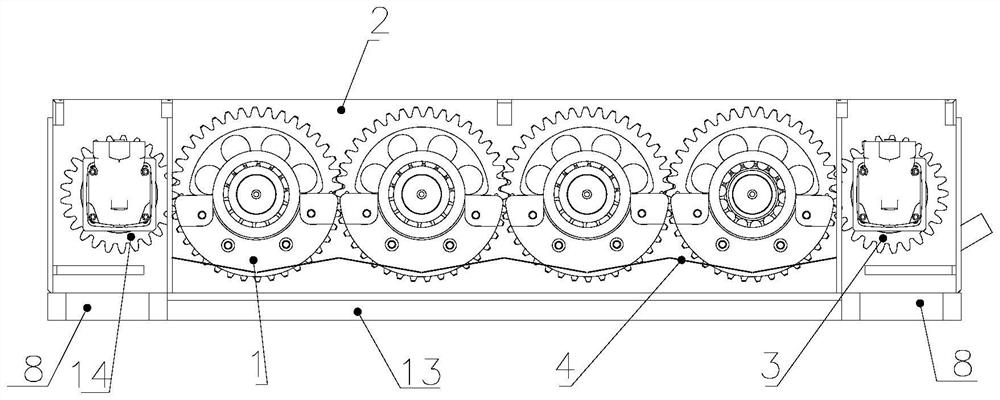

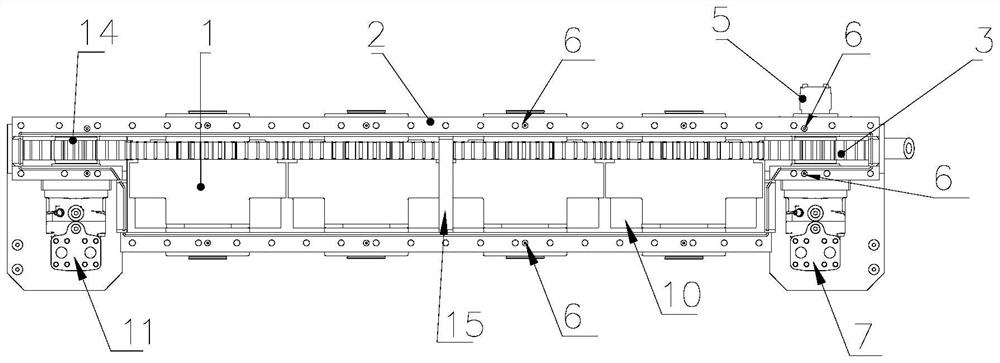

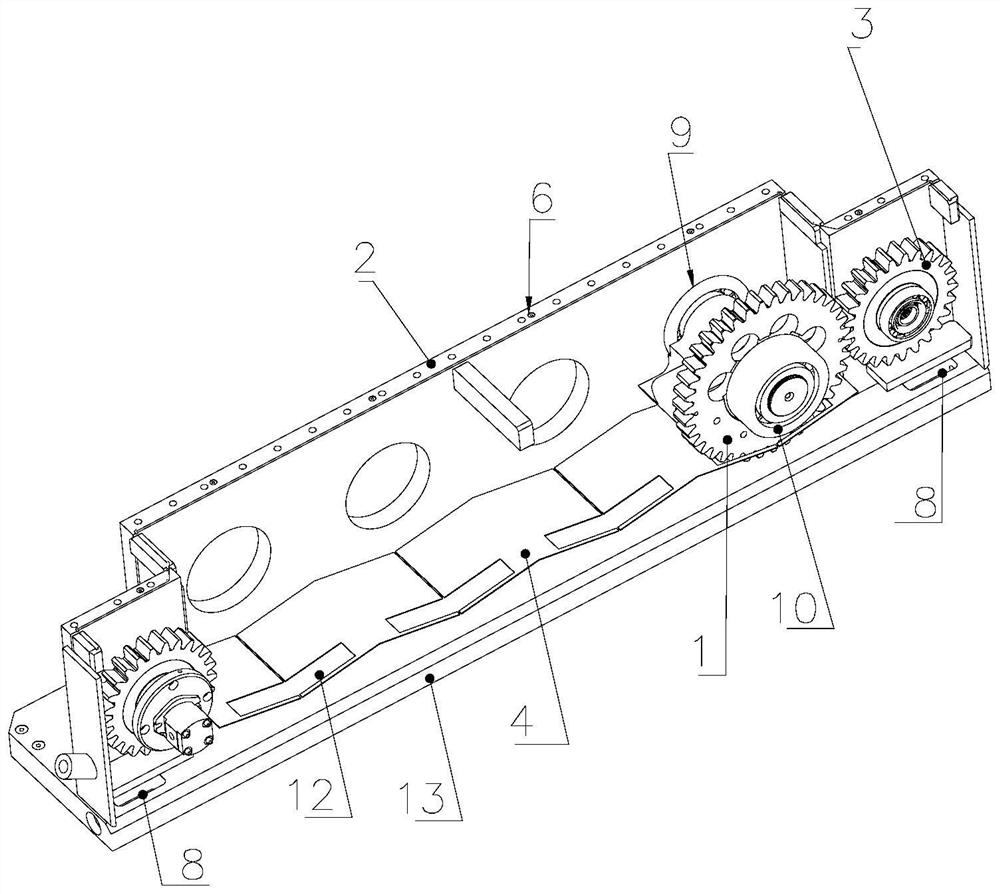

[0042] See attached figure 1 to attach Figure 5 The specific embodiment of the present invention discloses a large tonnage exciter, including a box body 2, a rotating shaft 15, an eccentric gear 1, a driving gear and a lubricating oil circulation system, and the box body 2 is provided with at least one set of bearing seats 9 , the two ends of the rotating shaft 15 are respectively arranged on the bearing housing 9 through the bearing 10, the eccentric gear 1 and the driving gear are respectively connected to the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com