Silicon carbide MPS diode with buried layer structure and preparation method thereof

A technology of silicon carbide and diodes, which is applied in the field of silicon carbide MPS diodes and its preparation, can solve problems such as diode failure and large PN junction conduction voltage, achieve high-current operating temperature reduction, reduce conduction resistance, and improve surge resistance The effect of current capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

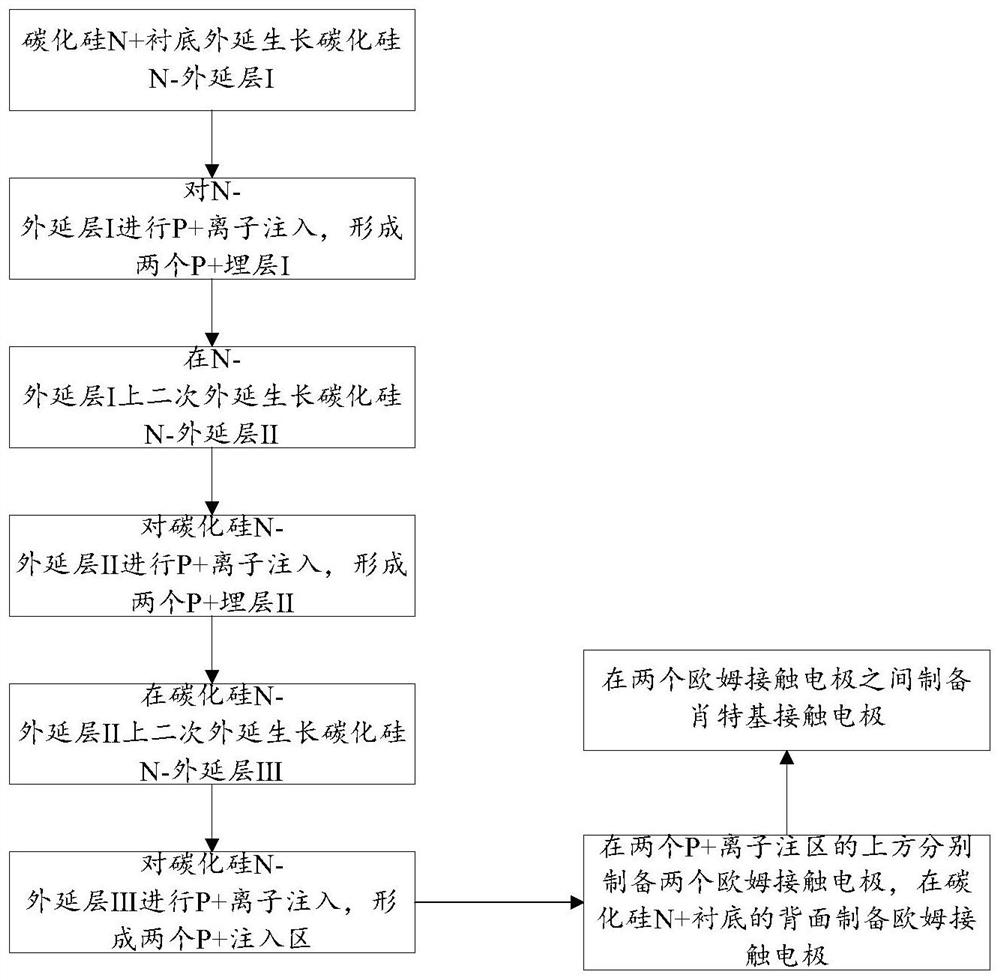

[0032] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

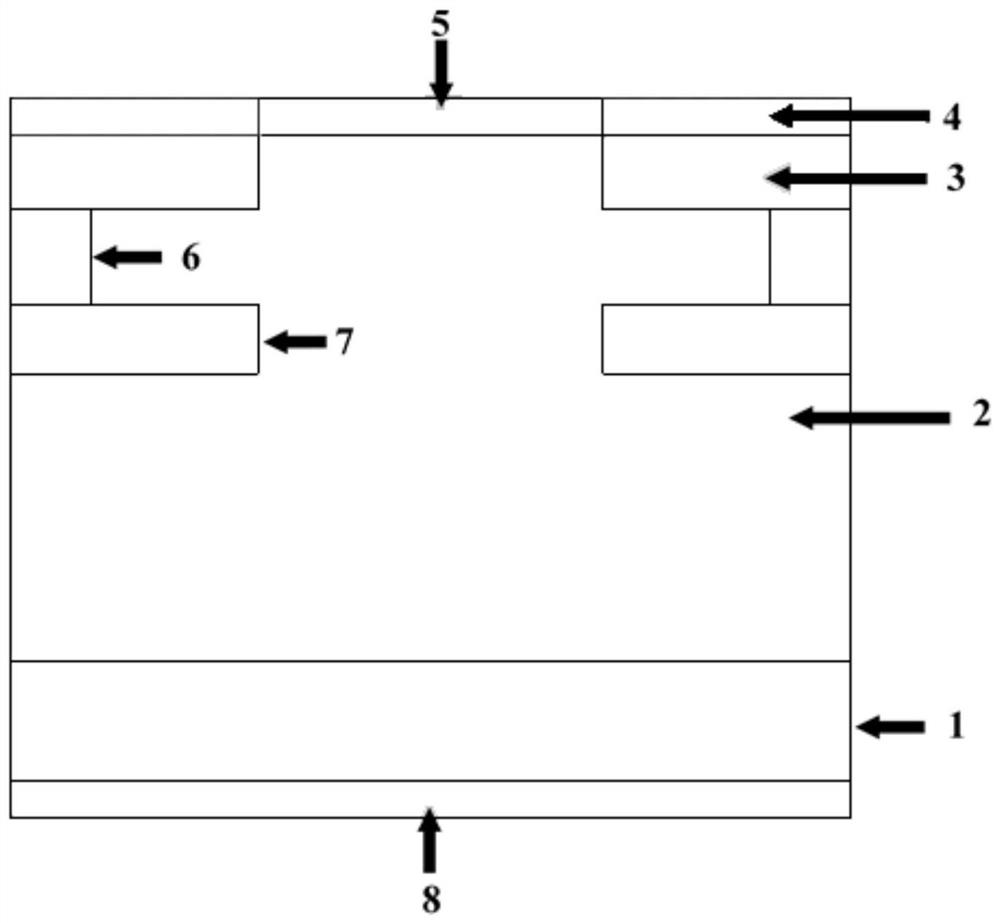

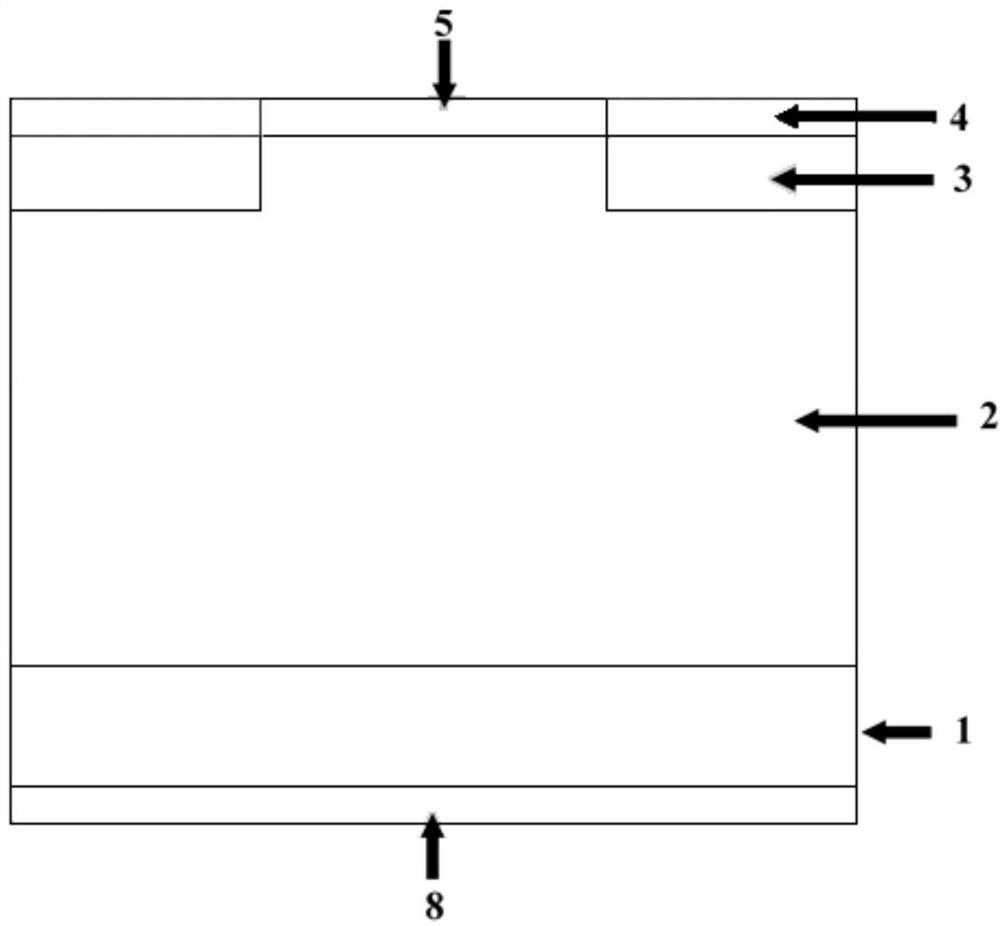

[0033] figure 1 The structure schematic diagram of the silicon carbide MPS diode with buried layer structure provided by the present invention, for the convenience of description, only shows the part related to the embodiment of the present invention.

[0034] The SiC MPS Diode includes:

[0035] A cathode ohmic contact electrode (8), a silicon carbide N+ substrate (1) and a silicon carbide N- epitaxial layer (2) stacked from bottom to top;

[0036] Two P+ implantation regions (3) are formed on the top of the silicon carbide N- epitaxial layer (2), the bottoms of the two P+ implantation regions (3) are in contact with the tops of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com