Monodisperse high-stability inorganic hydrated salt phase change nanocapsule as well as preparation method and application thereof

A technology of inorganic hydrated salts and nanocapsules, which is applied in the direction of microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of no phase change nanocapsules, etc., and achieve good market application prospects, stable performance, and packaging The effect of high coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

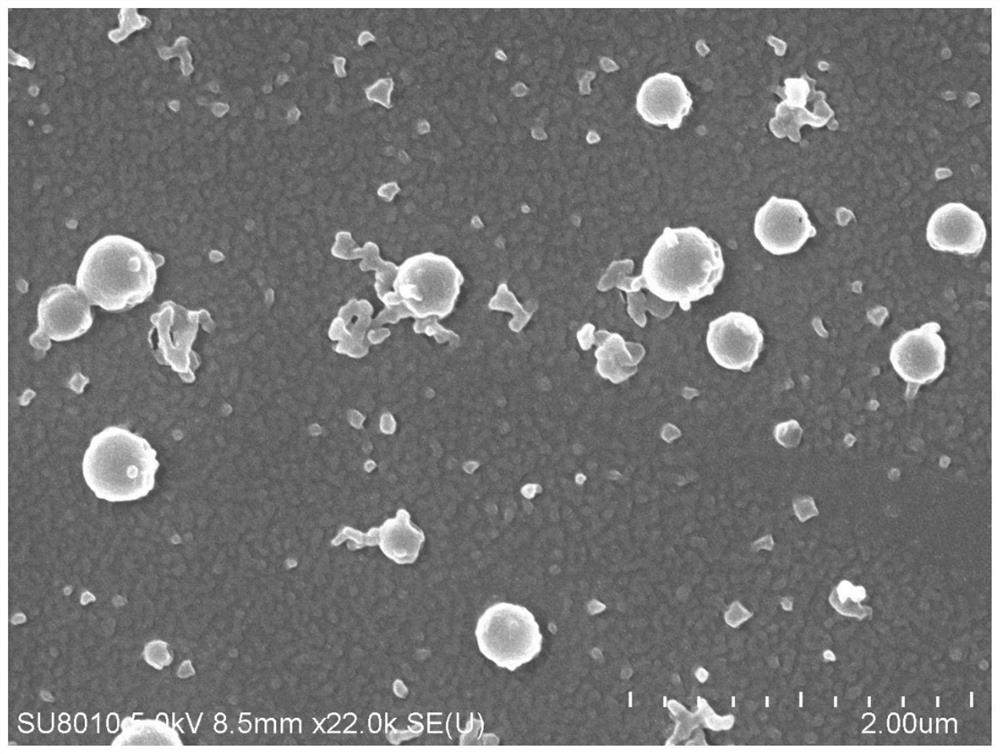

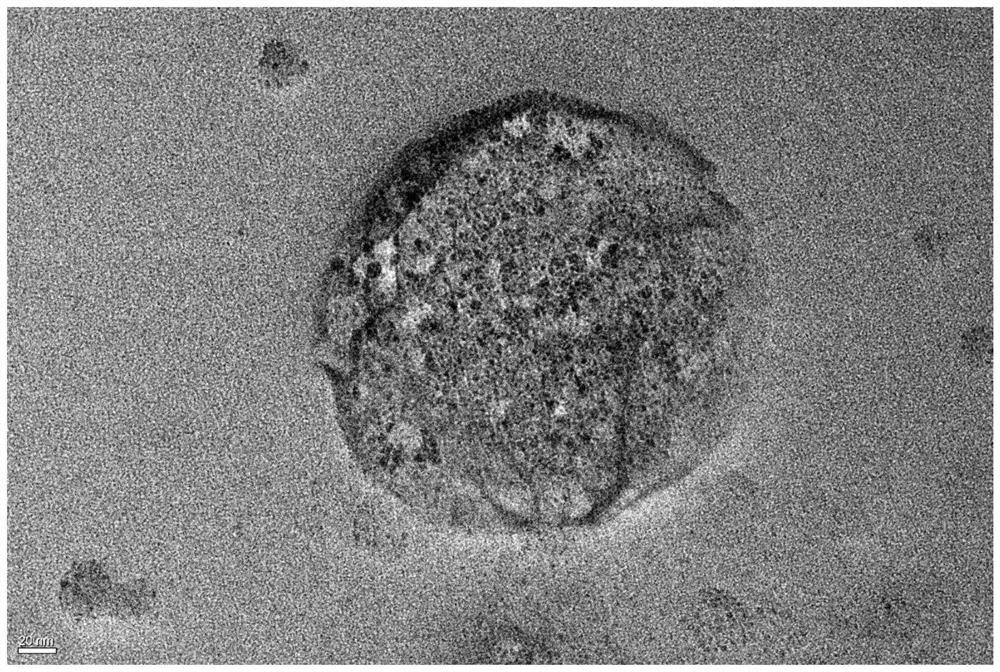

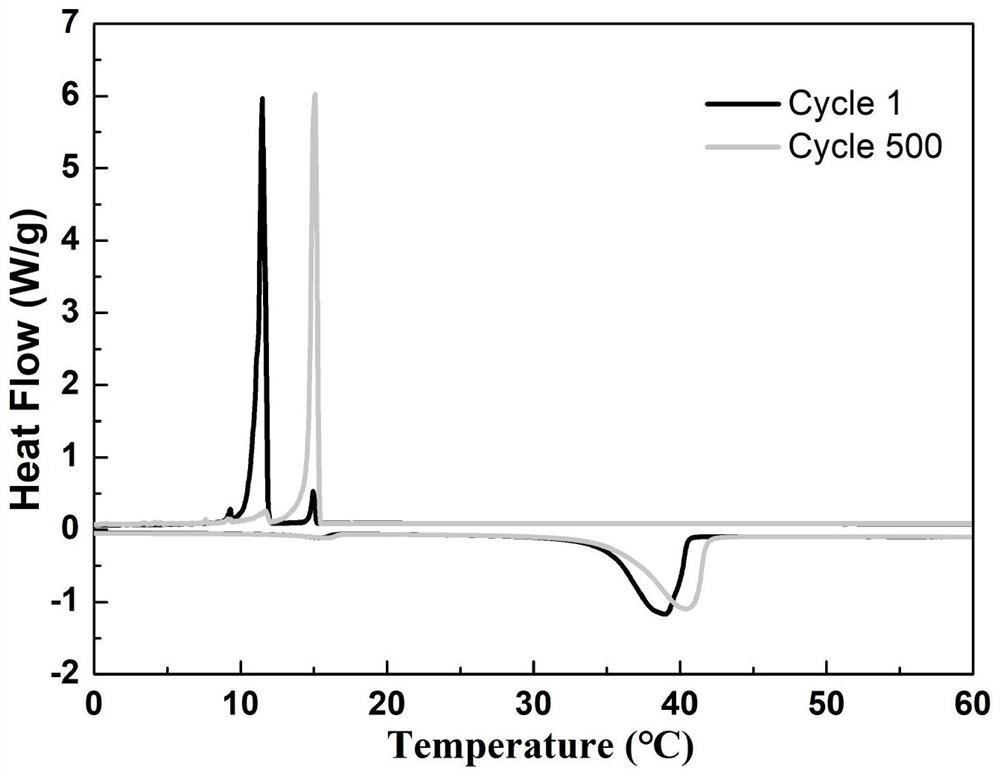

[0039] A preparation method of monodisperse highly stable inorganic hydrated salt phase-change nanocapsules, comprising the following steps:

[0040] (1) Preparation of water phase

[0041] Weigh 10g of disodium hydrogen phosphate dodecahydrate, 0.5g of Tween80 and 0.5g of maleic anhydride into a sample bottle, place it in a water bath at 50°C and heat it with stirring to melt it completely to obtain an aqueous phase;

[0042] (2) Preparation of oil phase A and oil phase B

[0043] Weigh 50ml of hexadecane into a 100ml beaker, heat to 50°C to obtain oil phase A; weigh 50ml of hexadecane, 5g of MMA and 0.1g of AIBN into a sample bottle, and place in an ultrasonic cleaner , sonicate for 10 minutes to obtain oil phase B;

[0044] (3) Preparation of core material emulsion

[0045] Add the water phase to the oil phase A, and emulsify it with a high-speed shearing machine at a shear rate of 7000 rpm for 5 minutes to obtain a core material emulsion;

[0046] (4) Preparation of hy...

Embodiment 2

[0049] A preparation method of monodisperse highly stable inorganic hydrated salt phase-change nanocapsules, comprising the following steps:

[0050] (1) Preparation of water phase

[0051] Weigh 10g of calcium chloride hexahydrate, 0.5g of Tween80 and 0.5g of maleic anhydride into a sample bottle, place it in a water bath at 50°C and heat it with stirring to melt it completely to obtain an aqueous phase;

[0052] (2) Preparation of oil phase A and oil phase B

[0053] Weigh 50ml of hexadecane into a 100ml beaker, heat to 50°C to obtain oil phase A; weigh 50ml of hexadecane, 5g of styrene and 0.1g of AIBN into a sample bottle, and place in ultrasonic cleaning In the device, ultrasonic for 10 minutes to obtain oil phase B;

[0054] (3) Preparation of core material emulsion

[0055] Add the water phase to the oil phase A, and emulsify it with a high-speed shearing machine at a shear rate of 12000 rpm for 5 minutes to obtain a core material emulsion;

[0056] (4) Preparation ...

Embodiment 3

[0059] A preparation method of monodisperse highly stable inorganic hydrated salt phase-change nanocapsules, comprising the following steps:

[0060] (1) Preparation of water phase

[0061] Weigh 10g of sodium acetate trihydrate, 0.5g of Tween80 and 0.5g of maleic anhydride into a sample bottle, place it in a water bath at 60°C and heat it with stirring to melt it completely to obtain an aqueous phase;

[0062] (2) Preparation of oil phase A and oil phase B

[0063] Weigh 50ml of hexadecane into a 100ml beaker, heat to 60°C to obtain oil phase A; weigh 50ml of hexadecane, 10g of styrene and 0.1g of AIBN into a sample bottle, and place in ultrasonic cleaning In the device, ultrasonic for 10 minutes to obtain oil phase B;

[0064] (3) Preparation of core material emulsion

[0065] The water phase is added in the oil phase A, and it is emulsified using a high-speed shearing machine at the same time, the shear rate is 15000rpm, and continues for 10min to obtain the core materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com