Method for oxidizing and activating coal gangue through subcritical/supercritical water

A technology of supercritical water oxidation and coal gangue, which is applied in the field of coal gangue activation, can solve the problems of high corrosion resistance of equipment, high energy consumption, and low resource utilization rate, so as to improve oxidation activation efficiency, easy to obtain raw materials, The effect of enhancing the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

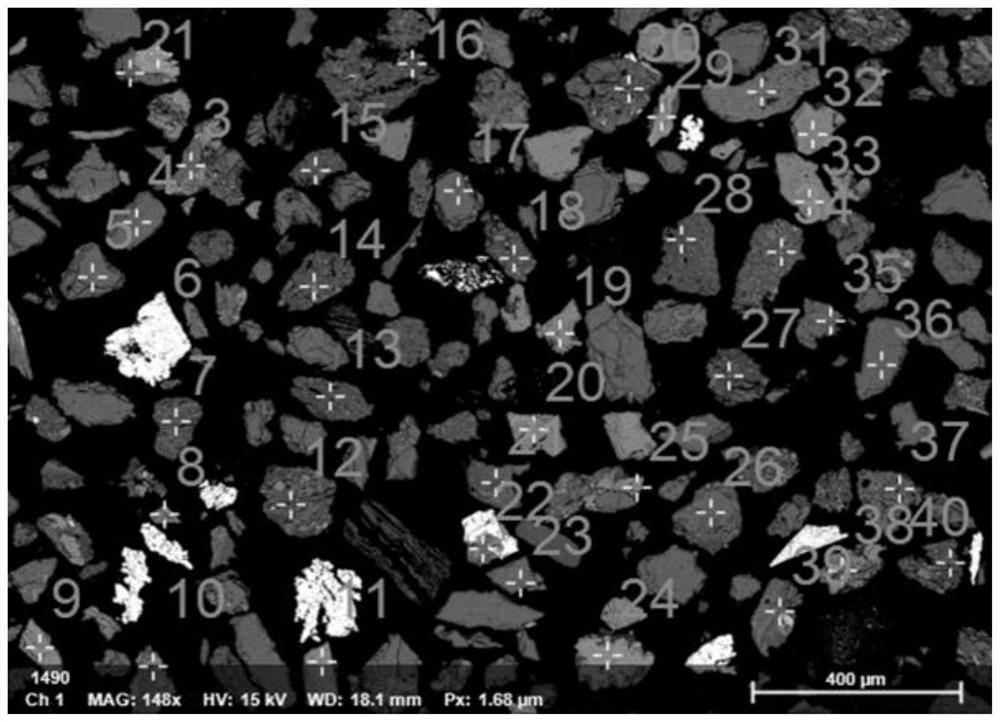

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for oxidizing and activating coal gangue with sub / supercritical water, comprising the following steps:

[0045] S1: Crushing and grinding coal gangue to obtain mineral powder with a particle size of 74 μm;

[0046] S2: Weigh 5% hydrogen peroxide solution and mineral powder at a mass ratio of 1:1.2, and mix them uniformly to obtain an activated precursor.

[0047] S3: The activated precursor was subcritically activated at 320° C. and 8 MPa for 30 minutes, filtered, washed, and dried to obtain activated gangue.

[0048] After activation, most of the carbon and silicon dioxide are exposed, which is beneficial for subsequent extraction and separation.

[0049]For example, use a hydrocyclone to classify the activated coal gangue obtained in this example into an organic liquid phase and a slag phase, and recycle the separated organic liquid phase, and the slag phase is passed through a shaking table to obtain carbon and silicon dioxide Conc...

Embodiment 2

[0054] This embodiment provides a method for oxidizing and activating coal gangue with sub / supercritical water, comprising the following steps:

[0055] S1: Crushing and grinding coal gangue to obtain mineral powder with a particle size of 36 μm;

[0056] S2: Weigh 5% hydrogen peroxide solution and mineral powder at a mass ratio of 1:1.5, and mix them uniformly to obtain an activated precursor.

[0057] S3: Subcritically activate the activated precursor for 30 minutes under the conditions of 250° C. and 20 MPa, filter, wash, and dry to obtain activated coal gangue.

[0058] After activation, most of the carbon and silicon dioxide are exposed, which is beneficial for subsequent extraction and separation.

[0059] For example, use a hydrocyclone to classify the activated coal gangue obtained in this example into an organic liquid phase and a slag phase, and recycle the separated organic liquid phase, and the slag phase is passed through a shaking table to obtain carbon and sili...

Embodiment 3

[0061] This embodiment provides a method for oxidizing and activating coal gangue with sub / supercritical water, comprising the following steps:

[0062] S1: Crushing and grinding coal gangue to obtain mineral powder with a particle size of 2 mm;

[0063] S2: Weigh 5% hydrogen peroxide solution and mineral powder at a mass ratio of 1:1, and mix them uniformly to obtain an activated precursor.

[0064] S3: subcritically activate the activated precursor at 400° C. and 15 MPa for 60 minutes, filter, wash, and dry to obtain activated gangue.

[0065] After activation, most of the carbon and silicon dioxide are exposed, which is beneficial for subsequent extraction and separation.

[0066] For example, use a hydrocyclone to classify the activated coal gangue obtained in this example into an organic liquid phase and a slag phase, and recycle the separated organic liquid phase, and the slag phase is passed through a shaking table to obtain carbon and silicon dioxide Concentrated ore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com