Method for reducing viscosity of thickened oil by using microbial conversion liquid

A technology for microbial transformation and viscosity of heavy oil, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of serious heat loss, decline in crude oil recovery, poor thermal energy utilization, etc., to promote stripping. , Amplify the effect of easy construction and viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

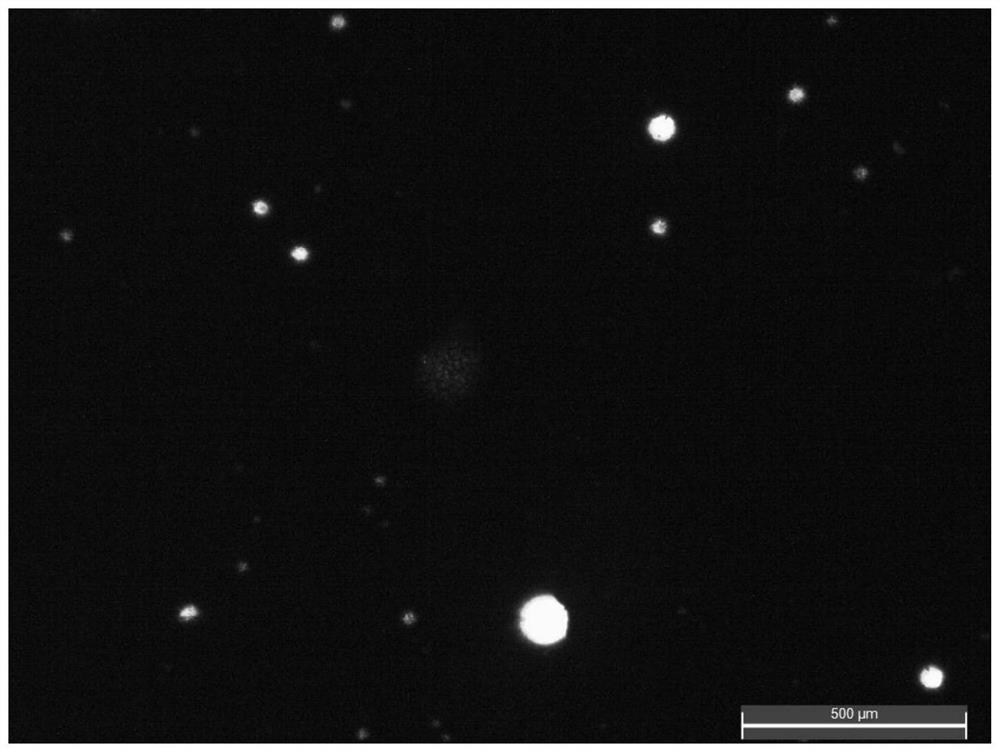

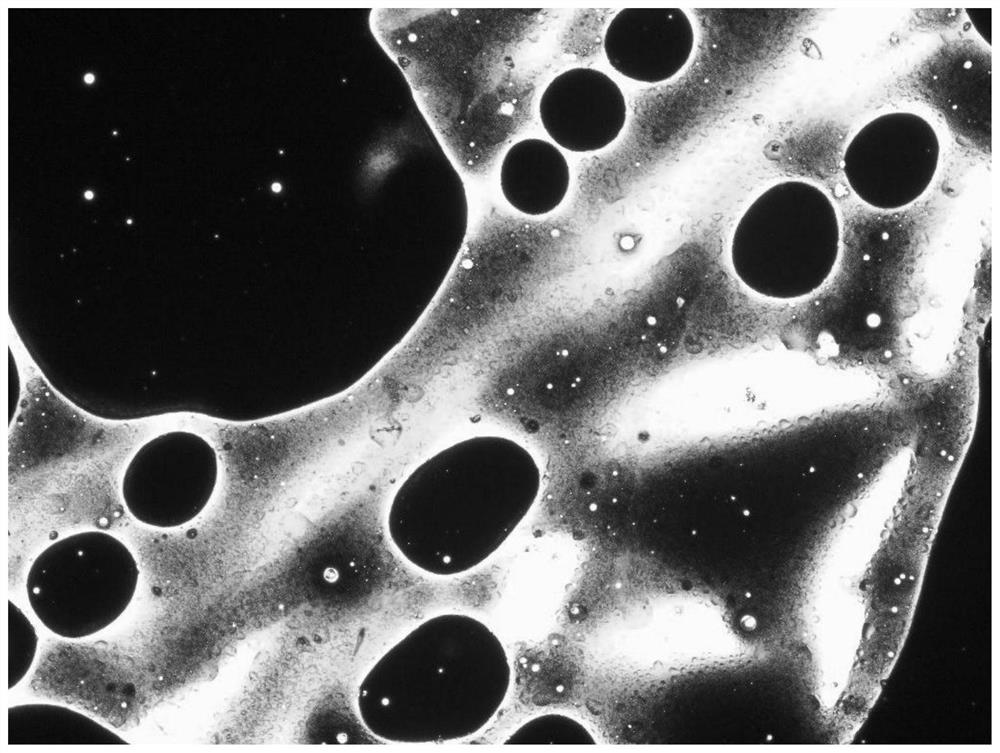

Image

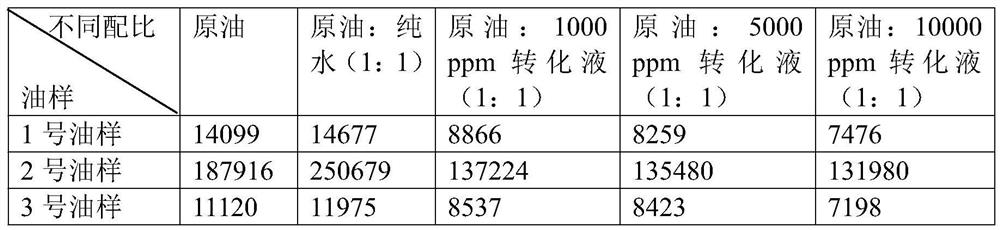

Examples

Embodiment 1

[0024] The microbial transformation solution preparation method of Corynebacterium glutamicum comprises the following steps:

[0025] 1) Cultivate Corynebacterium glutamicum preserved at -80°C for 12 hours at 30°C and 120rpm / min in LB liquid medium at a 5% (v / v) inoculum size;

[0026] 2) According to the inoculum amount of 5% (v / v), inoculate the bacterium cultivated in 1) into the CGXⅡ liquid medium, and cultivate it at 30°C and 120rpm / min for 12h; Body, frozen in -20 ℃ refrigerator for 12h, then thawed at room temperature;

[0027] 3) Prepare transformation solution: glucose concentration 15g / L, L-leucine concentration 11.2g / L, pH=8.0, 20mM PBS buffer;

[0028] 4) Put the thawed bacteria in step 2) into the transformation solution of step 3) at a concentration of 20 g / L, and perform a transformation reaction at 30° C. for 10 h; after the reaction, centrifuge the transformation solution, and take the centrifuged supernatant, namely For microbial transformation fluid.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com