Aerosol type composite material anti-corrosion primer and preparation method thereof

A composite material, anti-corrosion primer technology, applied in primers, anti-corrosion coatings, coatings and other directions, can solve problems such as poor compatibility, reduce coating corrosion current, and oil-based anti-corrosion coatings performance gap, etc., to achieve good weldability , Good storage stability and construction, convenient and simple construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

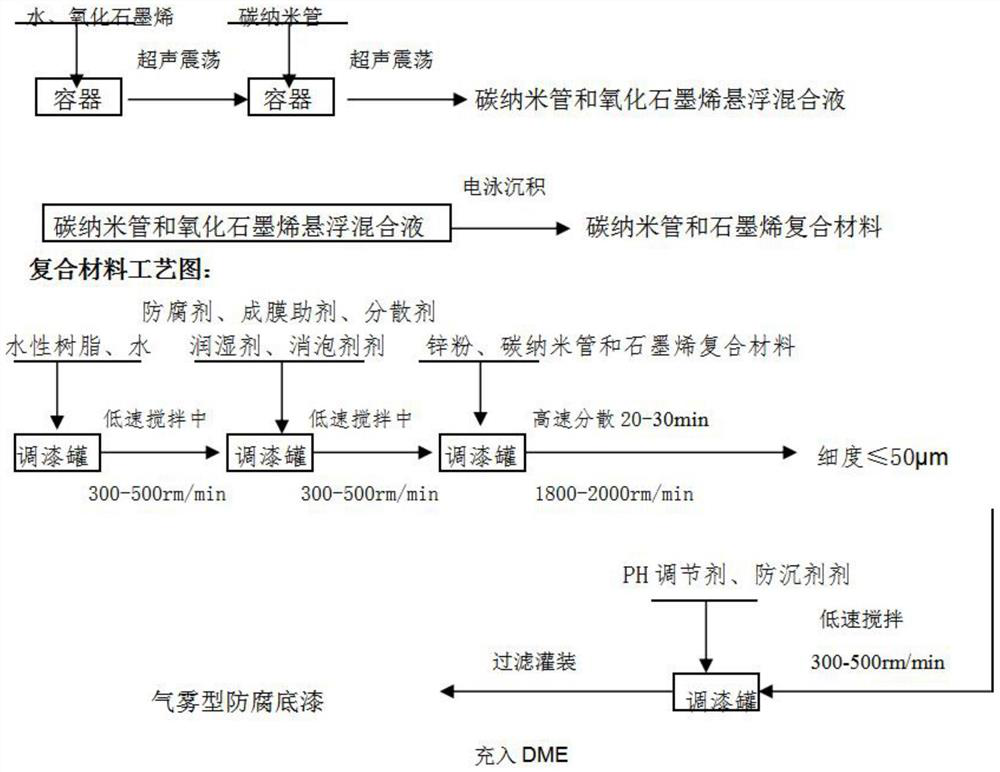

Method used

Image

Examples

Embodiment 1

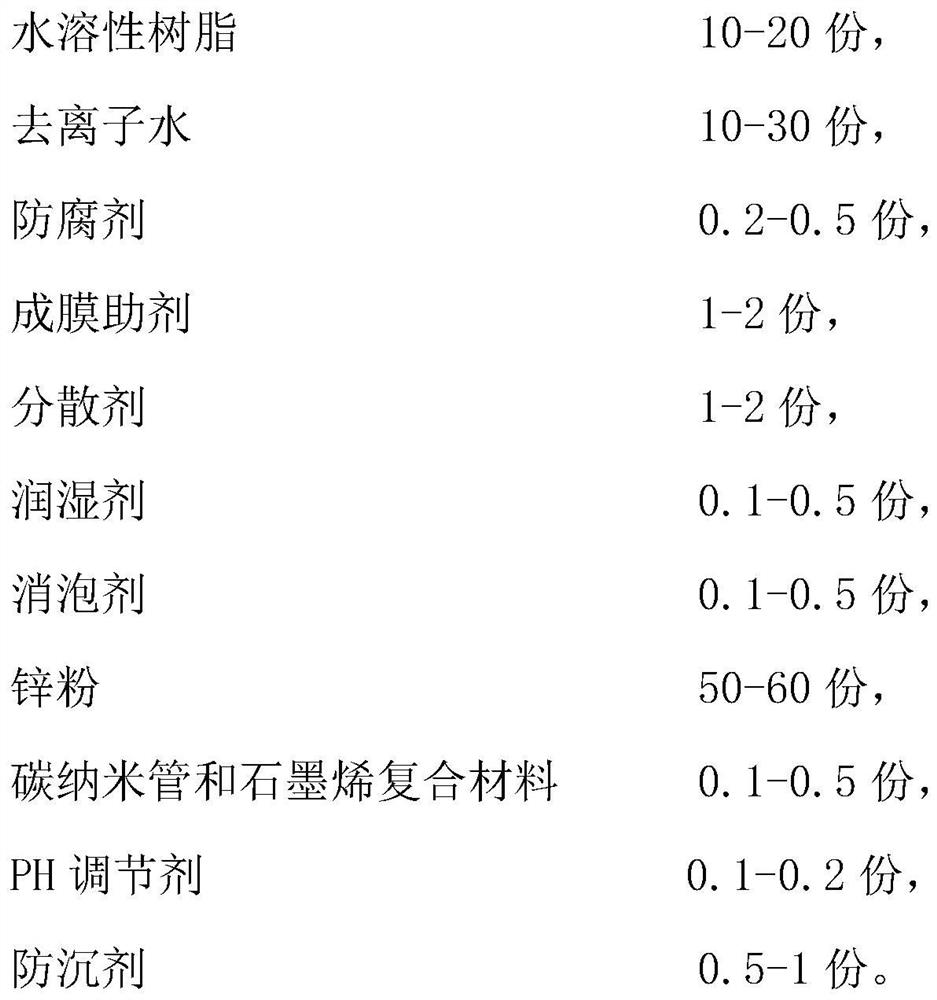

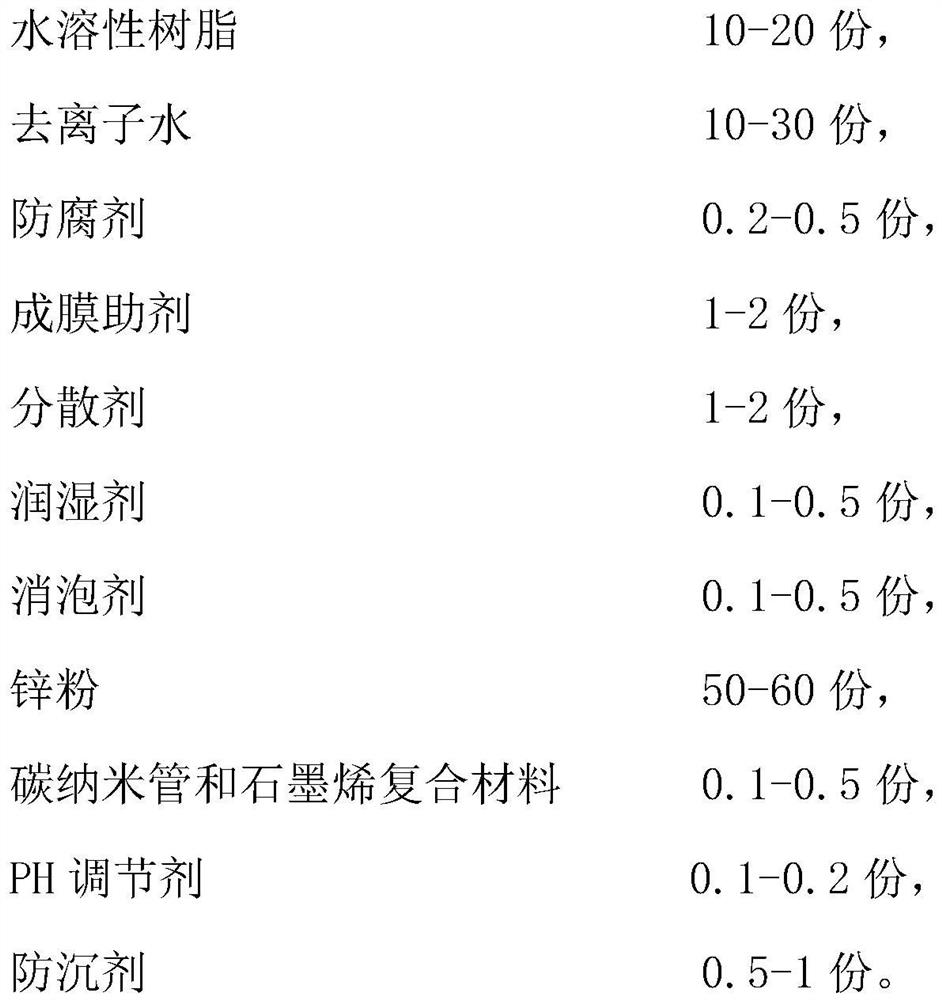

[0039] An aerosol type composite material anticorrosion primer, consisting of the following components in parts by weight:

[0040]

[0041]

[0042] In an optional embodiment, the water-based resin used is a high-molecular water-soluble epoxy-modified silicone resin containing low-polarity groups, the solid content is 55%, and the minimum film-forming temperature MFT is 25°C. Epoxy value (effective solid content) 0.06.

[0043] In an optional embodiment, the carbon nanotube and graphene composite material used has a particle size of less than 50 nanometers, and the weight ratio of carbon nanotubes to graphene is 0.6:1.

[0044] In an optional embodiment, the dispersant used is an acrylic-polyurethane copolymer dispersant with a polymer block structure, and the solid content is 50%.

[0045] In an optional embodiment, the preservative used is an isothiazolinone derivative, the film-forming aid used is alcohol ether, and the defoamer used is a polyether modified silicone...

Embodiment 2

[0059] An aerosol type composite material anticorrosion primer, consisting of the following components in parts by weight:

[0060]

[0061]

[0062] In an optional embodiment, the water-based resin used is a high-molecular water-soluble epoxy-modified silicone resin containing low-polarity groups, the solid content is 55%, and the minimum film-forming temperature MFT is 22°C. Epoxy value (effective solid content) 0.15.

[0063] In an optional embodiment, the carbon nanotube and graphene composite material used has a particle size of less than 50 nanometers, and the weight ratio of carbon nanotubes to graphene is 0.8:1.

[0064] In an optional embodiment, the dispersant used is an acrylic-polyurethane copolymer dispersant with a polymer block structure, and the solid content is 50%.

[0065] In an optional embodiment, the anti-settling agent used is a polyamide polymer with a solid content of 21% and an acid value of 11 mgKOH / g.

[0066] An aerosol type composite mater...

Embodiment 3

[0078] An aerosol type composite material anticorrosion primer, consisting of the following components in parts by weight:

[0079]

[0080] In an optional embodiment, the water-based resin used is a high-molecular water-soluble epoxy-modified silicone resin containing low-polarity groups, the solid content is 55%, and the minimum film-forming temperature MFT is 23°C. Epoxy value (effective solid content) 0.1.

[0081] In an optional embodiment, the carbon nanotube and graphene composite material used has a particle size of less than 50 nanometers, and the weight ratio of carbon nanotubes to graphene is 1:1.

[0082] In an optional embodiment, the dispersant used is an acrylic-polyurethane copolymer dispersant with a polymer block structure, and the solid content is 50%.

[0083] In an optional embodiment, the preservative used is an isothiazolinone derivative, the film-forming aid used is alcohol ether, and the defoamer used is a polyether modified silicone type defoamer....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com