Preparation method of anti-crack putty powder for external wall insulation

An anti-cracking putty and external wall thermal insulation technology, applied in the direction of filling slurry, etc., can solve problems such as poor crack resistance, weak structure, safety accidents, etc., to relieve expansion stress, reduce shrinkage cracking, and enhance crack resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

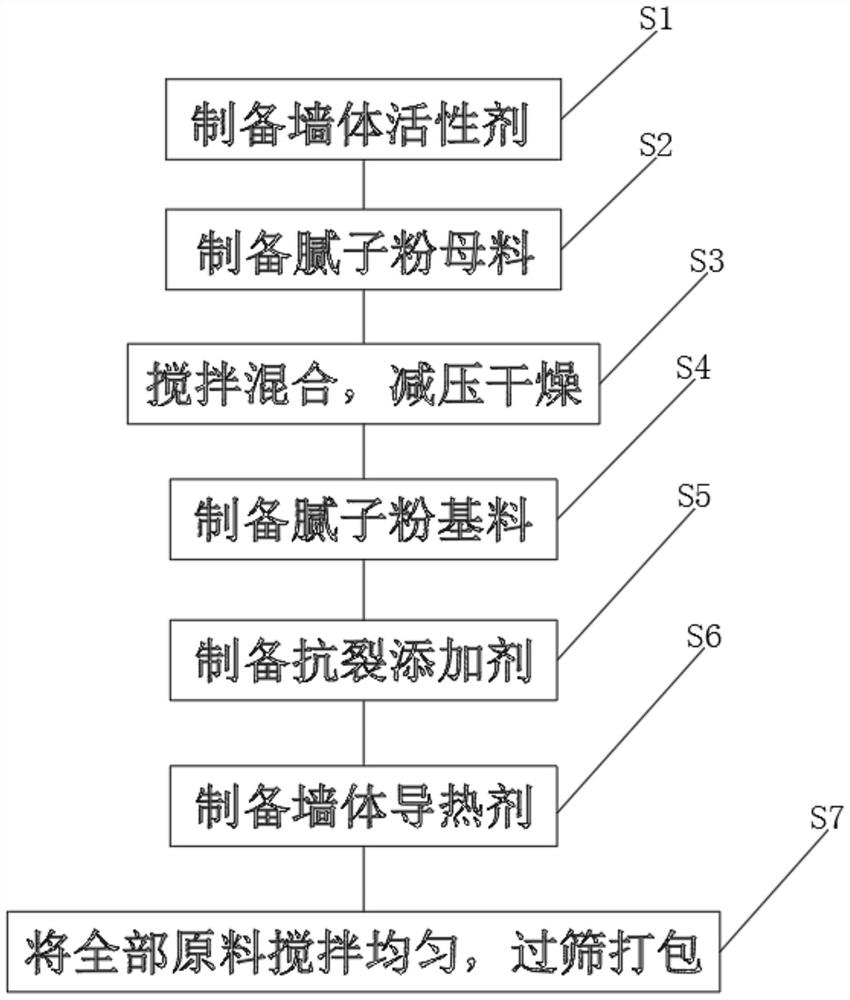

[0040] see figure 1 , the present invention provides a technical solution: a method for preparing putty powder for thermal insulation and anti-cracking of external walls, comprising the following steps:

[0041] Step 1, preparing the wall active agent.

[0042] 101) First, take an appropriate amount of p-toluene, toluene, and carbon tetrachloride, and fully stir and mix them at a temperature of 40-50° C. to obtain a mixture.

[0043] 102) Add the catalyst to the mixture while passing nitrogen gas, and the mass ratio of the catalyst to the mixture is 1:25, and fully stir and mix them at a temperature of 60-80°C.

[0044] 103) After S102, filter the catalyst-added mixture, and take out the filter residue for drying and washing to obtain a dried product.

[0045] 104) Add solvent and triethylamine to the dried product, stir and mix at 0-3°C to obtain a mixed solution.

[0046] 105) Add acryloyl chloride to the mixed liquid, stir and mix, filter with suction, take out the filte...

Embodiment 2

[0060] The preparation method of a kind of anti-cracking putty powder for external wall thermal insulation provided by this embodiment is roughly the same as that of Embodiment 1, and its main difference is:

[0061] In step S102, nitrogen gas is introduced into the mixture, and the mixture is fully stirred and mixed at a temperature of 60-80°C.

[0062] In step S104, a solvent is added to the dried product without adding triethylamine, and the mixture is stirred and mixed at 0-3° C. to obtain a mixed liquid.

[0063] In step S501, take an appropriate amount of polyacrylamide, add a small amount of N-methylpyrrolidone, and stir and mix at 15° C. to obtain a stirred mixture.

[0064] In step S503, the stirred mixture and the mixed raw materials are mixed together, stirred and mixed at a temperature of 15° C., then ethyl acetate is added, and after standing for a period of time, the precipitate is taken and dried to obtain an anti-cracking additive.

Embodiment 3

[0066] The preparation method of a kind of anti-cracking putty powder for external wall thermal insulation provided by this embodiment is roughly the same as that of Embodiment 1, and its main difference is:

[0067] In step S104, a solvent and a small amount of triethylamine are added to the dried product, and stirred and mixed at 0-3° C. to obtain a mixed solution.

[0068] In step S501, take an appropriate amount of polyacrylamide, add an equal amount of N-methylpyrrolidone, and stir and mix at a temperature of 15° C. to obtain a stirred mixture.

[0069] In step S503, the stirred mixture and the mixed raw materials are mixed together, stirred and mixed at a temperature of 20° C., then ethyl acetate is added, and after standing for a period of time, the precipitate is taken and dried to obtain an anti-cracking additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com