Scrap removing device and method for corrugated paper slotting unit

A groove unit and corrugated paper technology, applied in metal processing, etc., can solve the problems of affecting the production efficiency of the printing production line, unsatisfactory dust removal effect, and difficult to clean paper dust, so as to achieve good dust removal effect and avoid scratching The effect of wounding the sheave and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

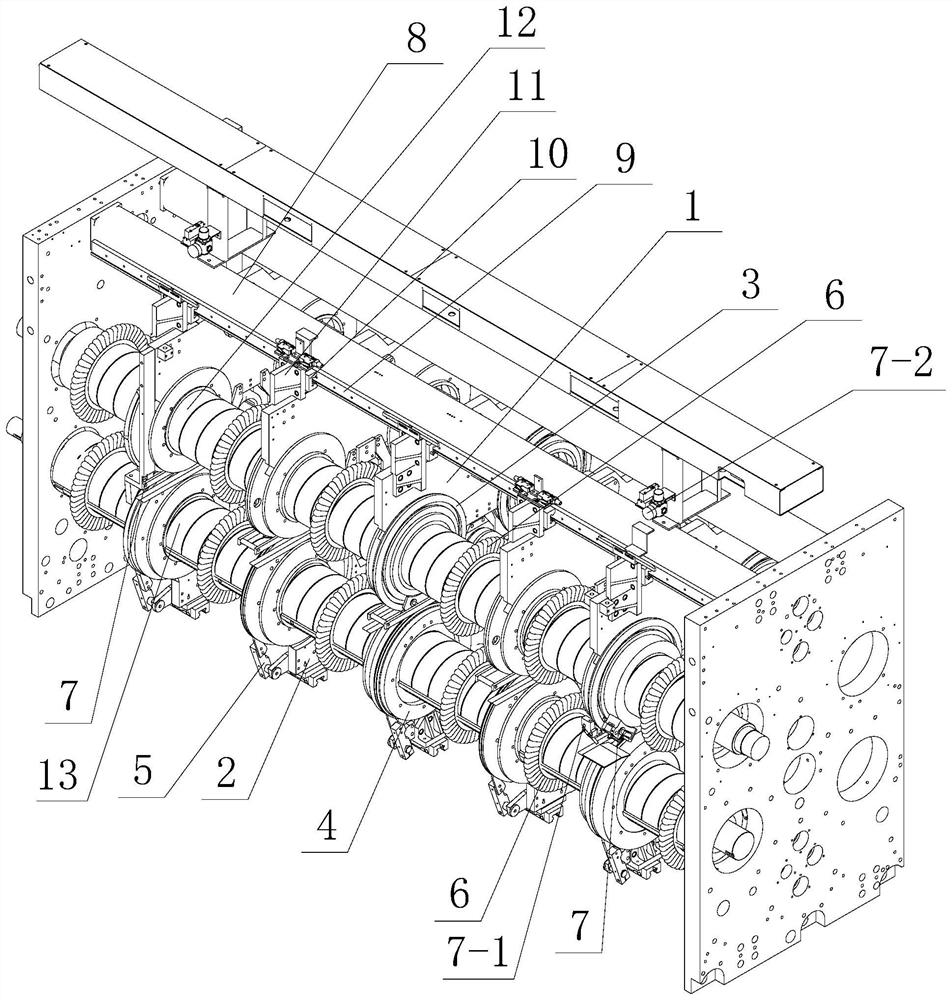

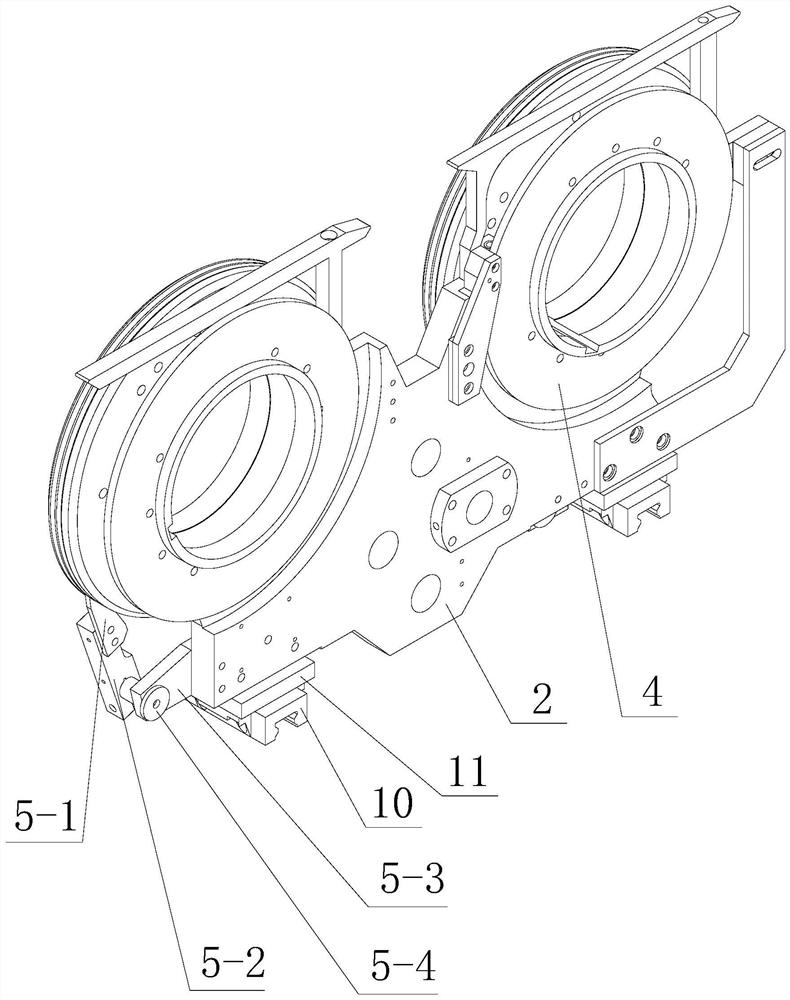

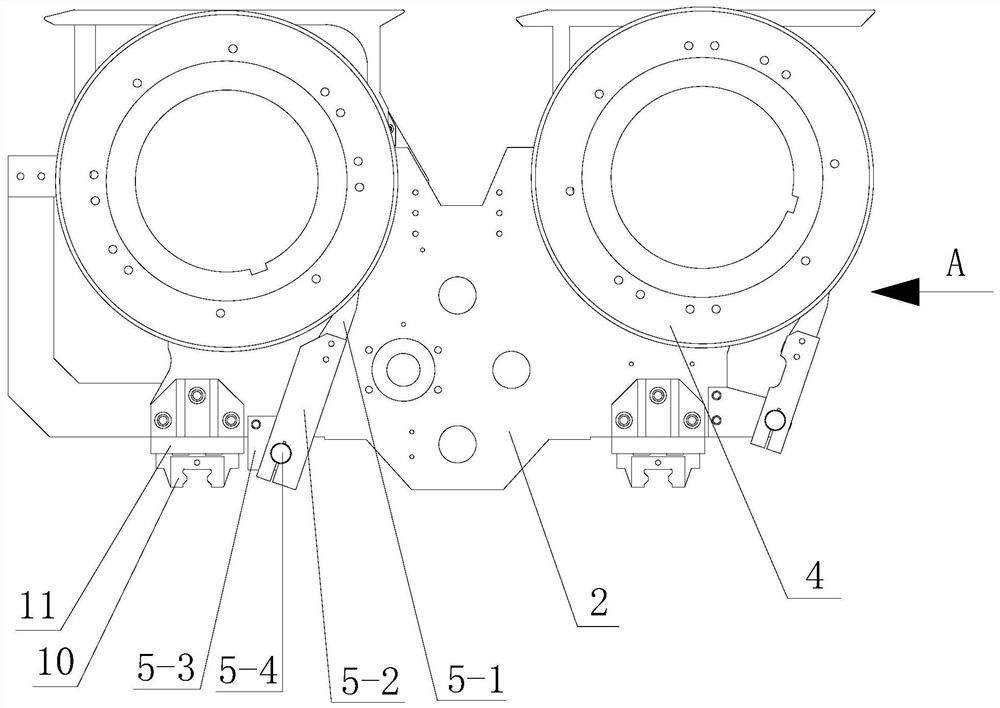

[0032] A chip removal device for corrugated paper slotting unit in this embodiment, such as figure 1 As shown, it includes the first guide plate 1, the second guide plate 2, the knife wheel 3, the groove wheel 4, the scraper mechanism 5, the brush 6 and the air duct assembly 7, and the first guide plate and the second guide plate are respectively installed On the frame 8 of the slotting unit, along the conveying direction of the corrugated cardboard, two cutter wheels are installed on each first guide plate, and two cutter wheels are installed on each second guide plate, the cutter wheel and The sieve wheels correspond to form a group of grooving knives, and each sieve wheel is equipped with a set of paper scraping mechanism; along the axis direction of the sieve wheel or sieve wheel, there are coaxial devices on both sides of each sieve wheel. There are also brushes arranged coaxially on both sides of each cutter wheel; air duct assemblies are installed on the first guide pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com