Recycling and purifying device for industrial sewage treatment

A technology for industrial sewage and purification devices, which is applied in mixers with rotary stirring devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of small contact area between industrial wastewater and chemical agents, poor purification effect, and inability to discharge. , to achieve the effect of prolonging the service life, improving the purification efficiency and improving the purification speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

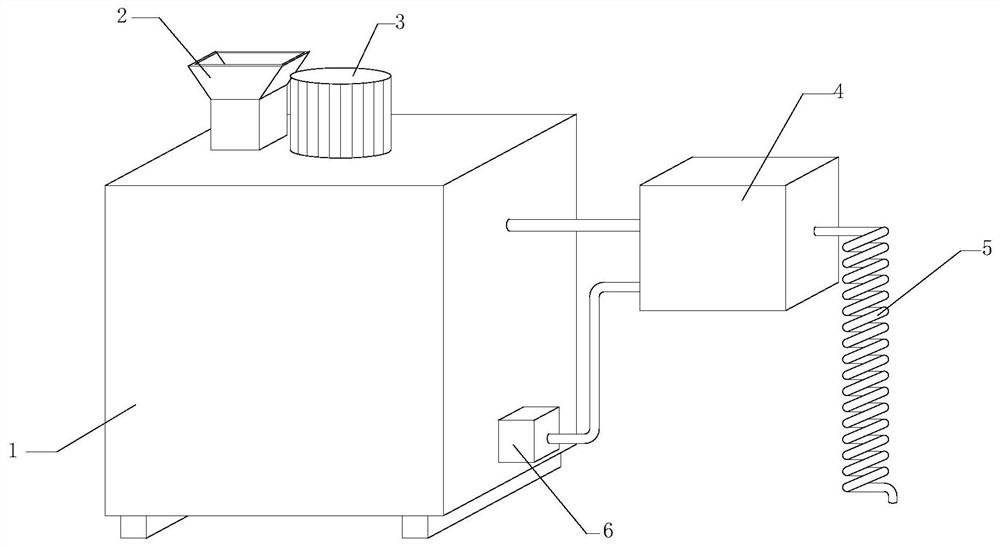

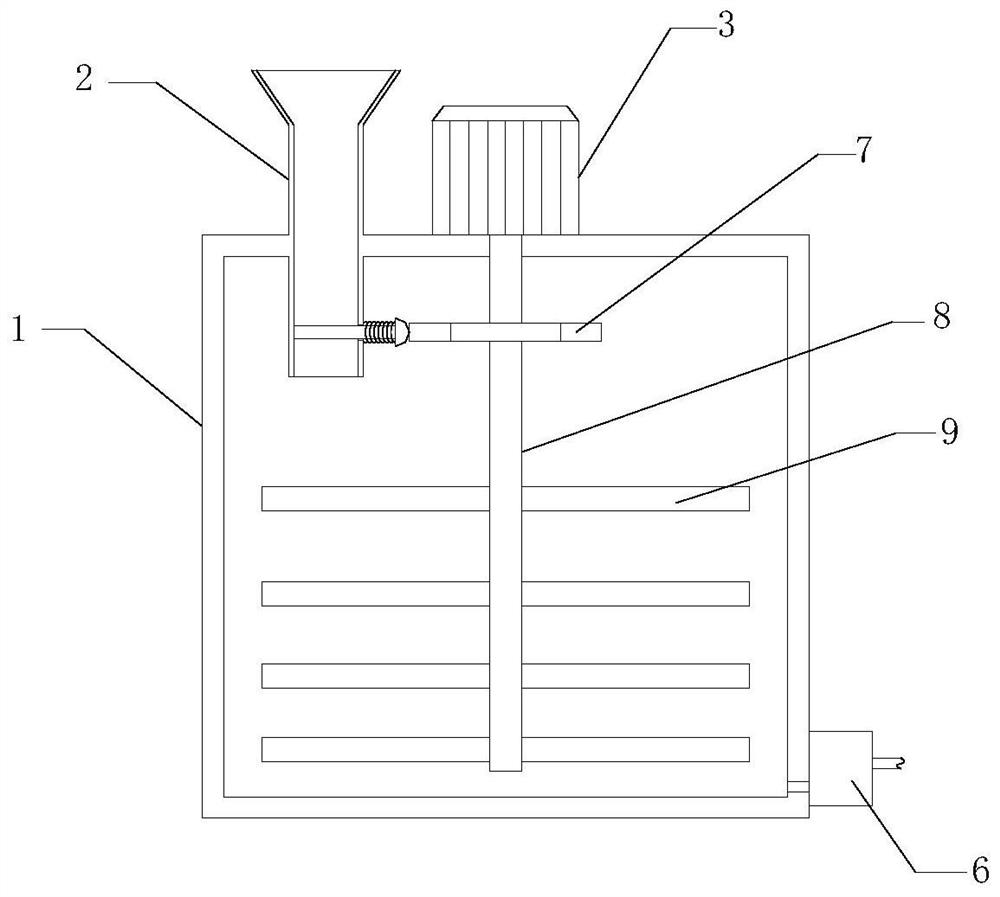

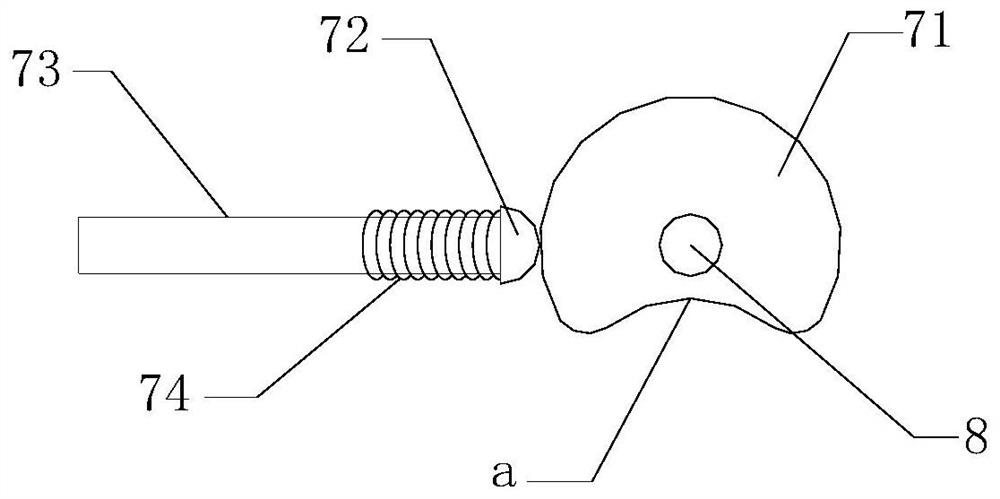

[0022] see Figure 1-3 , a recovery and purification device for industrial sewage treatment, comprising a chemical purification furnace 1, an upper hopper 2, a motor 3, a stirring shaft 8, a plurality of stirring blades 9, an intermittent feeding mechanism 7, a pump body 6, an annular drainage pipe 5 and a voltage stabilizing Mechanism 4, the side of the chemical purification furnace 1 is hinged with a furnace door, the upper hopper 2 is connected to the top of the chemical purification furnace 1 for industrial wastewater to enter the interior of the chemical purification furnace 1, and the motor 3 is welded on the top of the chemical purification furnace 1 The stirring shaft 8 is rotatably connected to the top of the chemical purification furnace 1, and is driven to rotate by the motor 3. The plurality of stirring blades 9 are arranged equidistantly in a circular shape on the annular side of the stirring shaft 8. The intermittent feeding mechanism 7 is located at Inside the c...

Embodiment 2

[0028] see Figure 4-Figure 6 , as an improvement of the above scheme, the pressure stabilizing mechanism 4 includes a stabilizing chamber 41, a piston plate 44, and a booster spring 46, and the stabilizing chamber 41 is provided with a material inlet 43 and a material outlet 45, and the outlet The feed port 45 is opened later than the feed port 43, the feed port 43 is connected to the discharge pipe of the pump body 6, the discharge port 45 is connected to the annular drainage pipe 5, and the piston plate 44 is slidably connected to the plenum chamber 41. inner wall, and the piston plate 44 divides the plenum chamber 41 into two mutually enclosed spaces, and the booster spring 46 is connected to the top wall of the plenum chamber 41 and tightly connected to the upper surface of the piston plate 44 .

[0029] As an improved solution to the above solution, several groups of booster springs 46 are provided, and the plurality of groups of booster springs 46 are equidistantly arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com