Novel composite steel keel-large plate structural system and construction method

A construction method and composite technology, applied in the direction of structural elements, floor slabs, building components, etc., can solve problems such as insufficient punching resistance of columns, troublesome formwork reinforcement construction, and damage to column-slab joints, etc., to facilitate construction and improve reliability. The effect of repeated utilization rate and fast construction depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

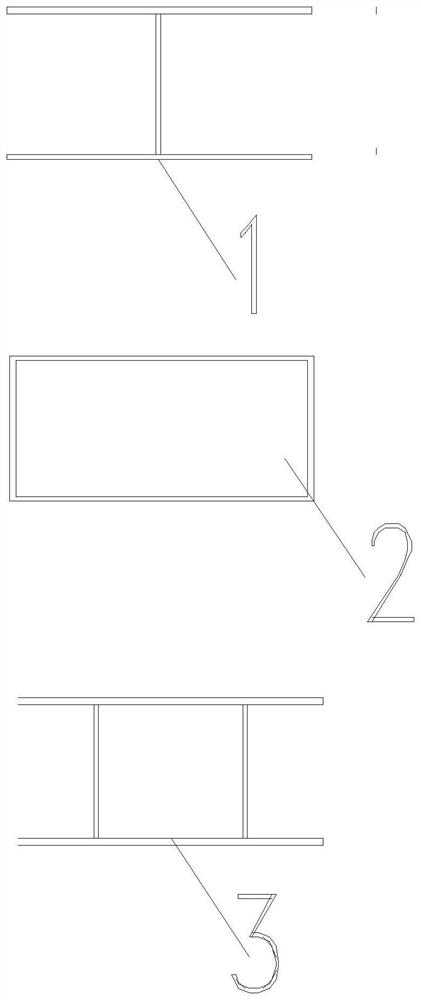

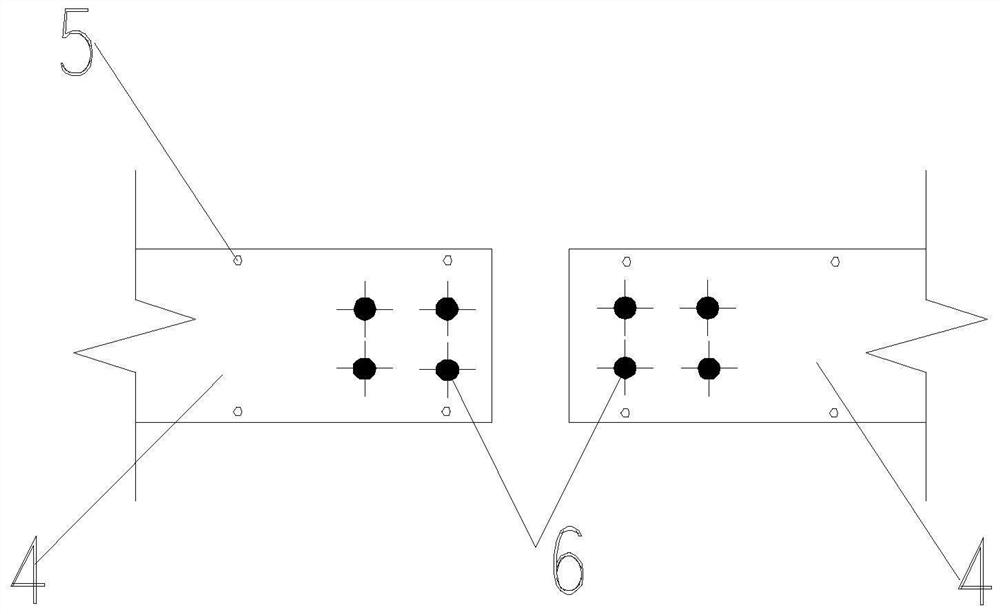

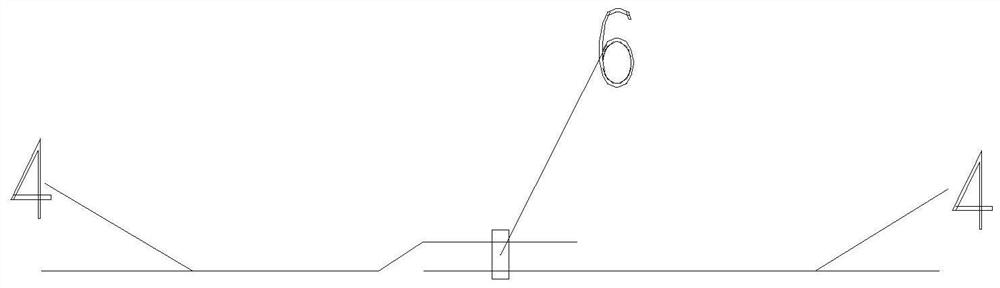

[0050] Such as Figure 1-3 As shown, it shows the partial structural diagram of the new composite steel keel-large slab structure system, including I-shaped steel 1, box-shaped steel 2, double I-shaped steel 3, steel structure 4, through hole 5, bolt 6, steel structure 4 includes I-shaped steel 1, box-shaped steel 2, and double I-shaped steel 3, which not only have high structural strength, but also reduce the amount of concrete pouring. The steel skeleton is in grid form with multiple steel structures 4 overlapping, and the adjacent steel structures 4 are fixed by bolts 6 . The steel structure 4 is also distributed with a plurality of through holes 5 for passing through the steel bars of the pillars. The through-hole spacing is 200mm and the diameter is 12mm.

[0051] Such as Figure 4 As shown, the first composite roof includes a steel frame 7 and concrete, and the concrete is poured around the steel frame 7, and the steel frame 7 is formed of a plurality of overlapping s...

Embodiment 2

[0058] The composite roof of the present invention will be further described below in conjunction with the installation method of a novel composite steel keel-large slab structure system and construction method of the present invention. The composite roof installation method includes the following steps:

[0059] S1. According to the engineering requirements of the project, use the elastic plate to design the basement roof, and use the principle of equivalent substitution to replace the steel bar, that is, the area of the steel bar in the unit area is equal to the area or the reinforcement ratio in the unit area of the steel skeleton, and draw the construction drawing;

[0060] S2. Prepare the first composite roof, the second composite roof, the third composite roof and the fourth composite roof; wherein, the first composite roof includes a steel skeleton and concrete, and the concrete is poured on the steel skeleton and a protective layer is left , the steel frame is grid-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com