Casting process of high-manganese steel lining plate used in as-cast state

A technology of high manganese steel lining plate and casting process, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of splashing water, staff slipping, wet environment, etc., to optimize the casting process and improve the safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

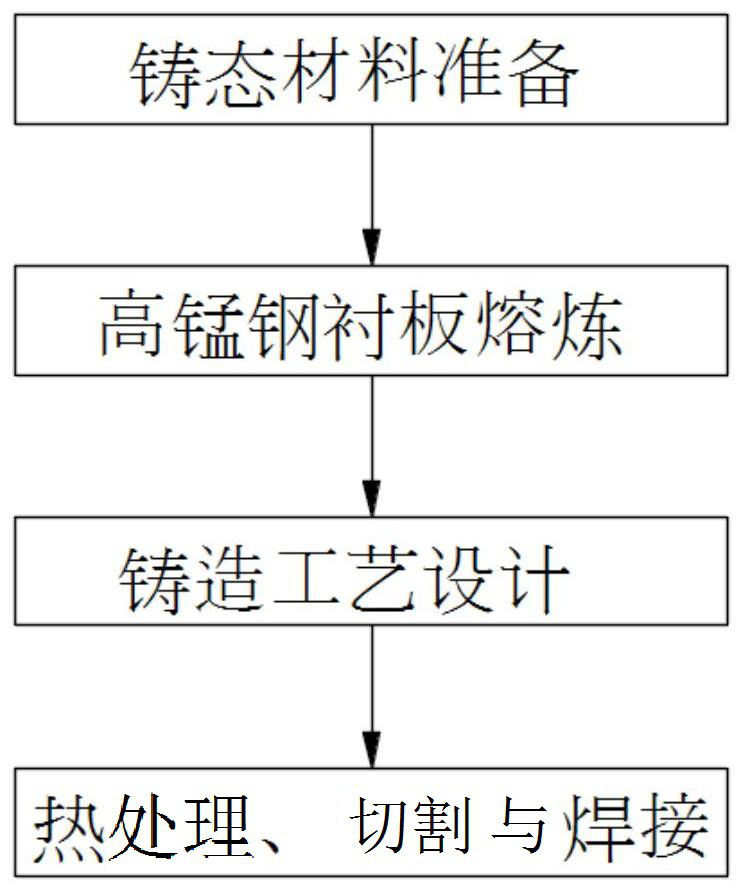

[0041] Such as Figure 1-5 As shown, the invention provides a casting process of the high manganese steel liner used in the cast state, the casting process of the high manganese steel liner used in the cast state comprises the following steps:

[0042] Step 1, the preparation of the furnace charge used in the cast state;

[0043] Step 2, smelting of high manganese steel lining board; charge and molding materials;

[0044] Step 3, casting process design;

[0045] Step 4, heat treatment, cutting and welding.

[0046] The preparation of the charge used in the cast state in the step 1 also includes: high-quality carbon steel, high-carbon ferromanganese, medium-carbon ferromanganese, and high-carbon ferrochrome.

[0047] The smelting of the high manganese steel liner in step 2 also includes the following steps:

[0048] A1: Put the smelted carbon steel into the furnace, add ferromanganese several times in small amounts, and finally add precious elements to reduce burning loss. ...

Embodiment 2

[0053] Such as Figure 1-5 As shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: preferably, casting process design in step 3 also includes the following steps:

[0054] B1: The gating system adopts an open type, and multiple scattered ingates are introduced from the thin wall of the casting, and are flat and wide in the shape of a trumpet. The cross-sectional area near the casting is larger than that connected to the runner, so that the metal The liquid is injected into the mold quickly and smoothly to prevent the temperature difference in the entire mold from being too large;

[0055] B2: The diameter of the riser should be larger than the diameter of the hot joint, close to the hot joint, and the height is 2.5-3.0 times of the diameter. The hot riser or even the pouring riser must be used in one, so that sufficient high-temperature molten metal can not be enough for the casting to solidify and shrink. the vacancy.

[0056] The ...

Embodiment 3

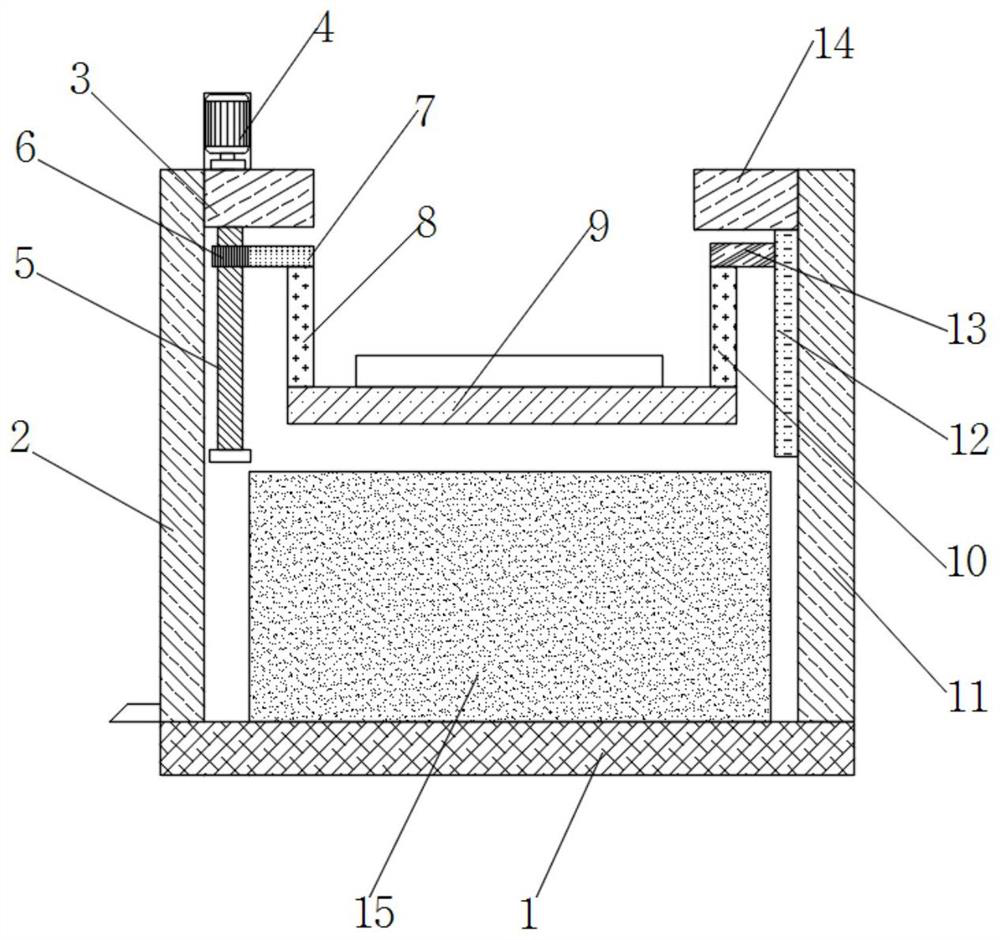

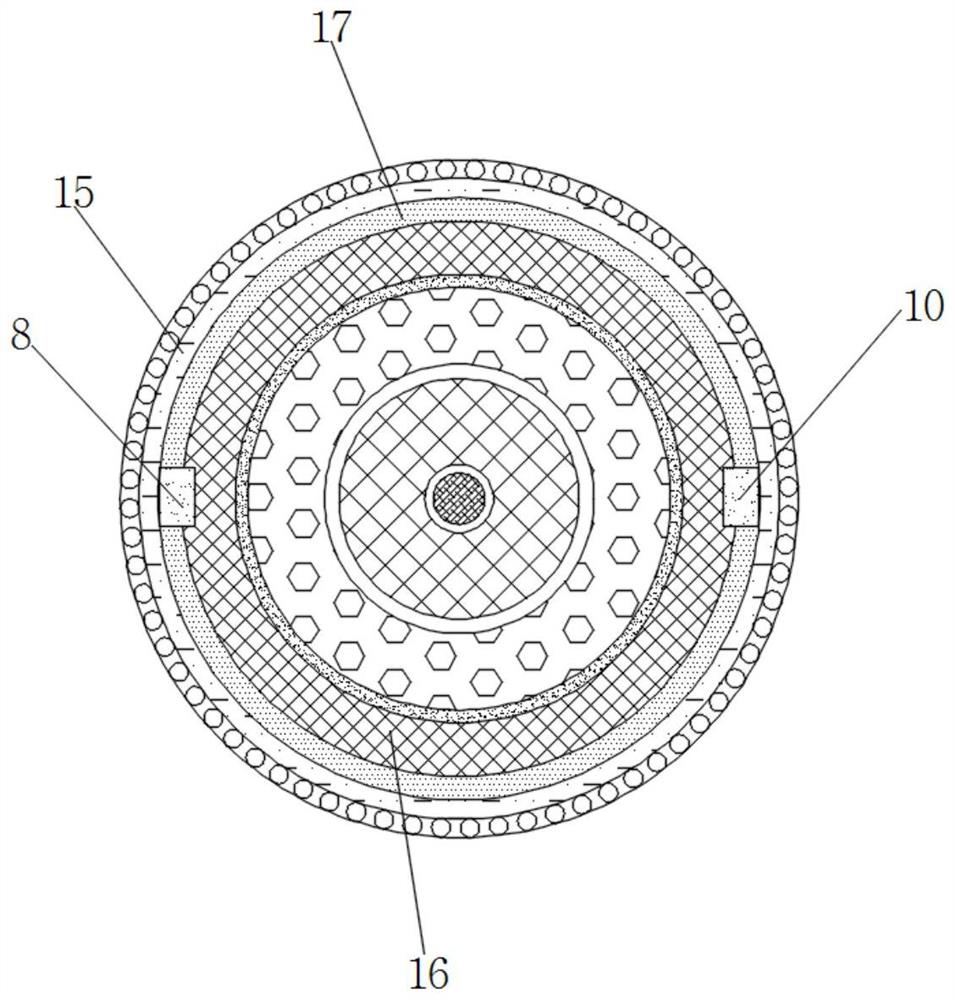

[0061] Second aspect, such as Figure 1-5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a casting quenching equipment for a high manganese steel liner used in the as-cast state, including a quenching pool 15, and a stable base 1 is provided at the bottom of the quenching pool 15, The upper left side of the stable base 1 is fixedly equipped with a first support vertical plate 2, the right side of the first support vertical plate 2 is fixedly equipped with a left horizontal plate 3, the top of the left horizontal plate 3 is fixedly equipped with a motor 4, and the left horizontal plate 3 The lower part of the screw rod 5 is provided with a screw rod 5, and an installation sleeve 6 is installed on the outside of the screw rod 5. The right side of the installation sleeve 6 is provided with a connecting rod 7, and the bottom of the connecting rod 7 is fixedly installed with a first elevating rod 8. The first elevating rod The bottom of 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com