Pet food production system

A production system and pet food technology, applied in food science, animal feed, chemical/physical processes, etc., can solve problems such as increasing pets, shortening cooling time, and illness, and achieve the production of various types of food, rich food nutrition, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with specific embodiments.

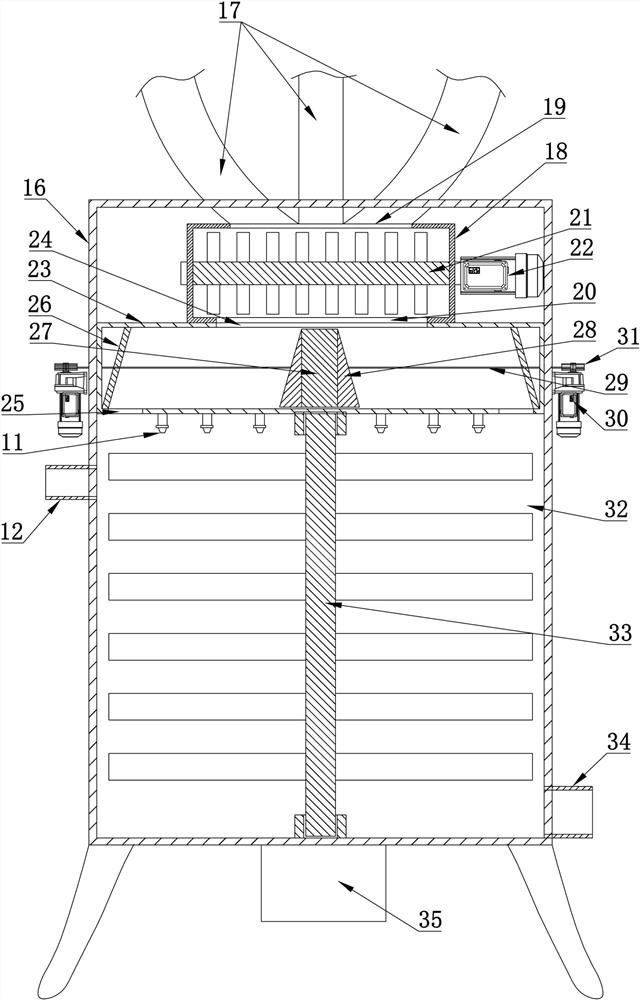

[0023] Such as figure 1 A pet food production system is shown, which includes: root vegetable processing device, leafy vegetable processing device, raw meat processing device, mixer 10 and mixed material processing device, and the root vegetable processing device includes sequentially connected slices Machine 1, conveyor 2, pulverizer 3 and feeder 4, described feeder 4 is connected with mixer 10; A feeder 4, the feeder 4 is connected with the mixer 10; the raw meat processing device includes a meat cutter 6, a meat grinder 7, a conveyor 2 and a feeder 4 connected in sequence, and the conveyor 2 is equipped with Heater 8 and ultraviolet sterilizer 9 are arranged, and described feeder 4 links to each other with agitator 10; Described mixed material treatment device compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com