Shale oil hydrotreating process and shale oil hydrotreating system

A technology of hydroprocessing and treatment process, which is applied in the field of oil processing, and can solve problems such as low porosity, increased pressure drop of the catalyst bed, and sudden increase of the pressure drop of the catalyst bed, so as to improve the operation cycle and reduce the pressure drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

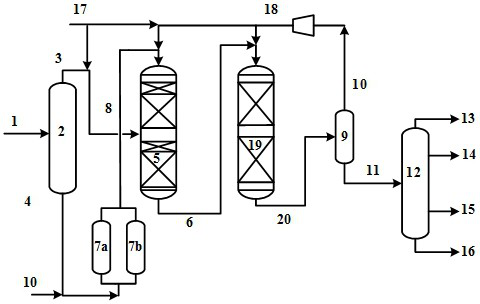

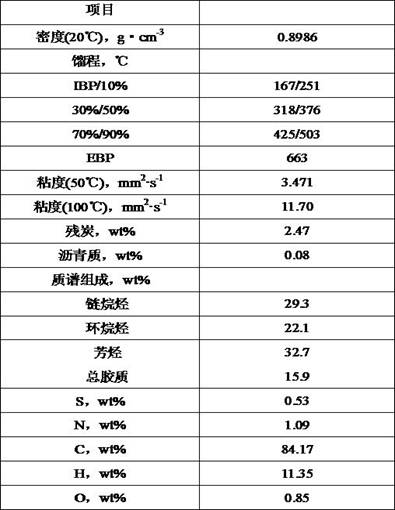

[0069] Taking the whole fraction of inferior shale oil in Table 1 as raw material, adopt figure 1 As shown in the process flow, the raw material is cut into two parts, the light fraction (167°C~350°C) and the heavy fraction (350°C~663°C) by the fractionation tower. The decontamination reactor is set up with three beds. The first bed is filled with TZ-1a, an adsorption catalytic decontamination material. The material shape is a seven-hole ball, the particle diameter is 25mm, and the inner diameter is 2.5mm. Active metal; the second bed is filled with TZ-2a, an adsorption catalytic impurity removal material, whose material shape is bird's nest type, the particle diameter is 18mm, the pore volume is 0.50mL / g, and the alumina is used as the matrix MoO 3 The component content is 6.5wt%, and the NiO component content is 1.2wt%; the third bed is filled with TZ-3a, an adsorption catalytic impurity removal material, whose material shape is Raschig ring type, the particle diameter is 8m...

Embodiment 2

[0071] Taking the whole fraction of inferior shale oil in Table 1 as raw material, adopt figure 1 As shown in the process flow, the raw material is cut into two parts, the light fraction (167°C~300°C) and the heavy fraction (300°C~663°C) by the fractionation tower. The decontamination reactor is set up with three beds, the first bed is filled with TZ-1b, an adsorption catalytic decontamination material, whose material shape is seven-hole sphere, the particle diameter is 20mm, the inner pore diameter is 1.8mm, and alumina is used as the matrix MoO 3 The component content is 7.5wt%; the second bed is filled with adsorption catalytic impurity removal material TZ-2b, whose material shape is bird's nest type, the particle diameter is 12mm, the pore volume is 0.45mL / g, and alumina is used as the matrix MoO 3 The component content is 8.5wt%, and the NiO component content is 1.5wt%; the third bed is filled with TZ-3b, an adsorption catalytic impurity removal material, whose material s...

Embodiment 3

[0073] Taking the whole fraction of inferior shale oil in Table 1 as raw material, adopt figure 2 As shown in the process flow, the raw material is cut into two parts, the light fraction (167°C~339°C) and the heavy fraction (339°C~663°C) by the fractionation tower. The decontamination reactor is set up with three beds, the first bed is filled with TZ-1c, an adsorption catalytic decontamination material. 3 The component content is 1.0wt%; the second bed is filled with adsorption catalytic impurity removal material TZ-2c, whose material shape is bird's nest type, the particle diameter is 24mm, the pore volume is 0.52mL / g, and alumina is used as the matrix MoO 3 The component content is 3.5wt%, and the NiO component content is 0.25wt%; the third bed is filled with TZ-3c, an adsorption catalytic impurity removal material, whose material shape is Raschig ring type, the particle diameter is 17.5mm, and the pore volume is 0.59 mL / g, with alumina as matrix MoO 3 The component conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com