Preparation method of refrigeration-free anti-reflection InP-based quantum dot/quantum well coupled EML epitaxial wafer

A quantum well and quantum-based technology, which is applied in the direction of phonon exciters, the structure of optical resonators, laser components, etc., can solve the problems of increasing device cost and complexity, and achieve wide applicability, good effect, and strong practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] A method for preparing an anti-reflection InP-based quantum dot / quantum well coupled EML epitaxial wafer without refrigeration, comprising the following steps:

[0046] Step 1. Select InP substrate A: the substrate is n + Type indium phosphide single wafer, crystal orientation is (100), doped element Si, doping concentration is (1-3)×10 18 cm -3 .

[0047] Step 2, performing the first epitaxial growth of the quantum dot stack on the InP substrate A; the epitaxial growth methods include molecular beam epitaxy and metal organic chemical deposition.

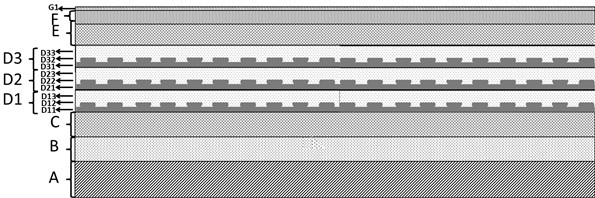

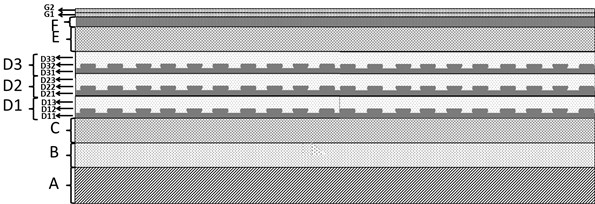

[0048] The structure grown for the first time is InP buffer layer B, InGaAsP lower confinement layer C, InAs / InGaAsP quantum dot active layer, InGaAsP upper confinement layer E, InGaAsP Gallium arsenide phosphorous grating layer F and indium phosphide capping layer G1, the structure is as follows figure 1 shown.

[0049] Wherein, the thickness of the indium phosphide buffer layer (B) is 500nm;

[0050] The thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grating period | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com