Biodegradable memristor array with information storage function and preparation method

A technology for information storage and memristors, which is applied in the field of biodegradable memristor arrays and preparations, can solve the problems of multiple structural levels, limited solution conditions, and difficult integration, and achieve simple preparation process, good mechanical toughness, and stable switching performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

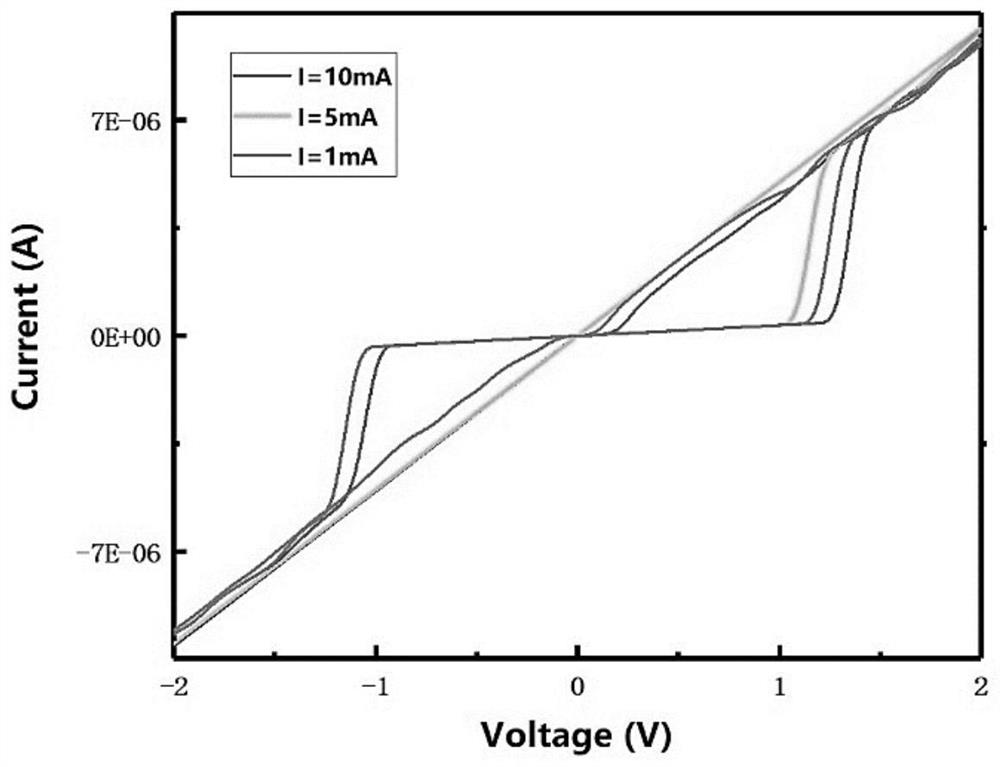

Examples

Embodiment 1

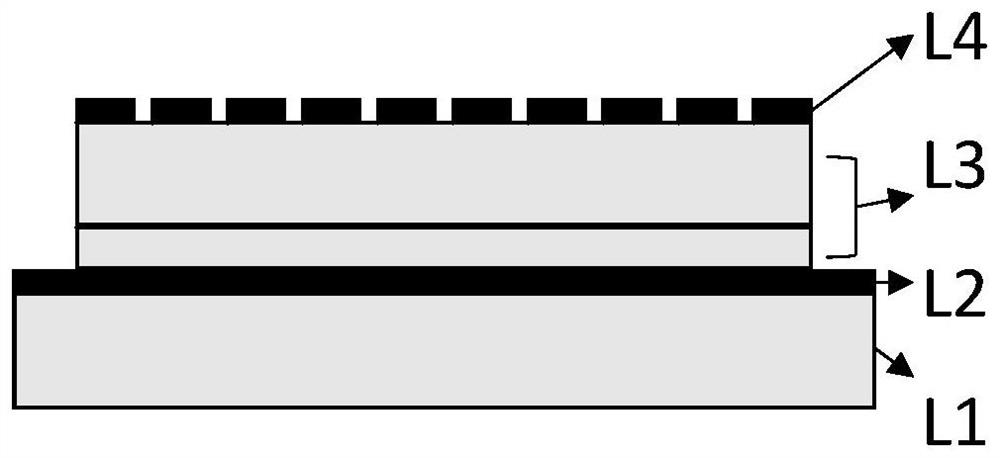

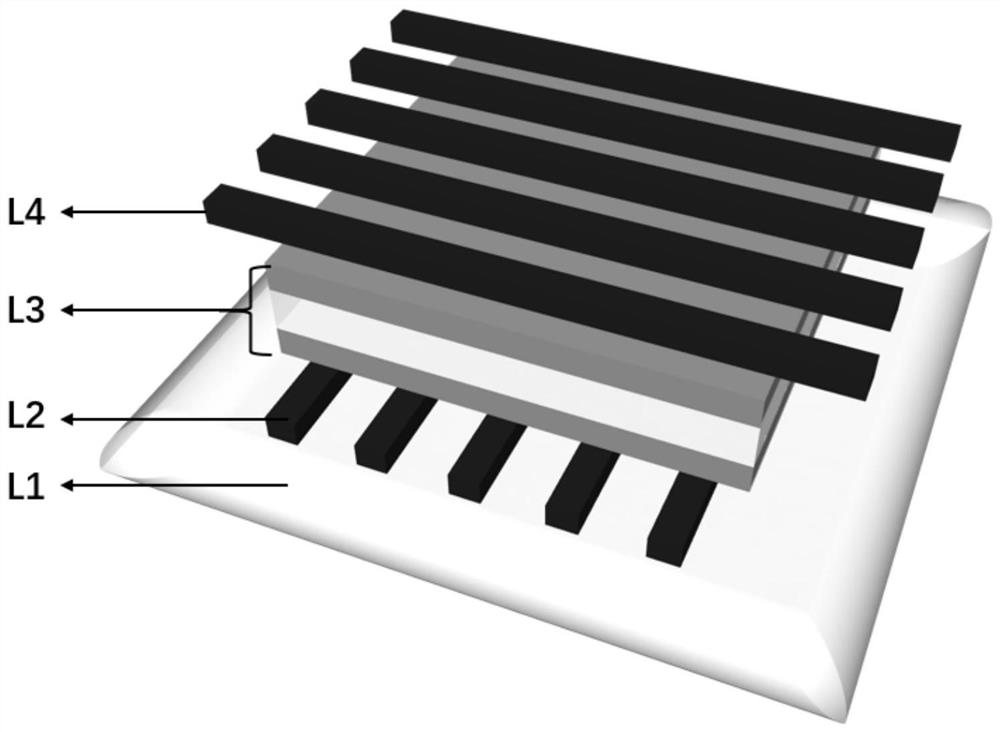

[0050] Preparation method of biodegradable memristor array with information storage function:

[0051] Step 1: Mix the regenerated silk fibroin solution made of natural silk material with the enhancer in a certain ratio, disperse it in the culture dish without air bubbles, and form a smooth and highly transparent silk fibroin composite film after evaporating water;

[0052] Step 2: After the silk fibroin composite film is made, perform plasma cleaning treatment on the surface of the silk fibroin composite film;

[0053] The third step: cover the mask pattern on the surface of the silk fibroin composite film, and use a silver target with a purity of 99.9% for magnetron sputtering to manufacture multiple parallel lower electrode silver strips with a thickness of 300-500nm;

[0054] Step 4: Make a dielectric layer on the lower electrode, first pre-spin the regenerated silk fibroin solution to prepare a buffer layer, and after drying, mix 1mL of silver nanowire-regenerated silk fi...

Embodiment 2

[0058] Preparation method of biodegradable memristor array with information storage function:

[0059] Step 1: Mix the regenerated silk fibroin solution made of natural silk material with the enhancer in a certain ratio, disperse it in the culture dish without air bubbles, and form a smooth and highly transparent silk fibroin composite film after evaporating water;

[0060] Step 2: After the silk fibroin composite film is made, perform plasma cleaning treatment on the surface of the silk fibroin composite film;

[0061] The third step: cover the mask pattern on the surface of the silk fibroin composite film, and use a silver target with a purity of 99.9% for magnetron sputtering to manufacture multiple parallel lower electrode silver strips with a thickness of 300-500nm;

[0062] Step 4: Make a dielectric layer on the lower electrode, first pre-spin the regenerated silk fibroin solution to prepare a buffer layer, and after drying, mix 1mL of silver nanowire-regenerated silk fi...

Embodiment 3

[0066] Preparation method of biodegradable memristor array with information storage function:

[0067] Step 1: Mix the regenerated silk fibroin solution made of natural silk material with the enhancer in a certain ratio, disperse it in the culture dish without air bubbles, and form a smooth and highly transparent silk fibroin composite film after evaporating water;

[0068] Step 2: After the silk fibroin composite film is made, perform plasma cleaning treatment on the surface of the silk fibroin composite film;

[0069] The third step: cover the mask pattern on the surface of the silk fibroin composite film, and use a silver target with a purity of 99.9% for magnetron sputtering to manufacture multiple parallel lower electrode silver strips with a thickness of 300-500nm;

[0070] Step 4: Make a dielectric layer on the lower electrode, first pre-spin the regenerated silk fibroin solution to prepare a buffer layer, and after drying, mix 1mL of silver nanowire-regenerated silk fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com