Etching liquid activating agent as well as preparation method and application thereof

A technology of activator and etching solution, which is applied in the field of etching solution activator and its preparation, can solve the problems of affecting the production capacity of equipment, consuming a large amount of silicon wafers, and high cost, so as to improve equipment production capacity, speed up reaction and reduce activation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The embodiment of the present invention also provides a preparation method of an etching solution activator, the preparation method comprising:

[0044] S01, dissolving surfactant, catalyst and dispersant in water to obtain a mixed solution.

[0045] Specifically, the surfactant, catalyst and dispersant are added to water, stirred and ultrasonically treated to uniformly dissolve the surfactant, catalyst and dispersant in the water. Wherein, the water is deionized water, and the temperature of the deionized water may be 65° C. during dissolution.

[0046] Optionally, the ultrasonic treatment conditions are: ultrasonic power 3000W, frequency 20KHz, temperature 40°C, ultrasonic duration 40min.

[0047] S02, adding silicon powder into the mixed solution to obtain an activator for etching solution for crystalline silicon solar cells.

[0048] In the preparation method of the etching solution activator provided in the embodiment of the present invention, a mixed solution ca...

Embodiment 1

[0052] Embodiment 1: This embodiment provides a production method of a monocrystalline silicon solar cell, the production method comprising:

[0053] S11. Texturing treatment.

[0054] Specifically, the surface of the monocrystalline silicon wafer is textured with an alkaline solution. The alkali solution may be NaOH solution with a mass concentration of 2.1%. A trough-type texturing machine can be used to perform texturing reaction on silicon wafers for 420 seconds at a temperature of 82°C and a mass concentration of NaOH of 2.1% to obtain a textured surface.

[0055] S12. Diffusion treatment.

[0056] Specifically, a tube-type diffusion furnace is used to perform diffusion treatment on the silicon wafer under the conditions of a temperature of 850° C., a negative pressure of 100 mBar, and a nitrogen flow rate of 1000 sccm / min to form a PN junction.

[0057] S13. Laser doping treatment.

[0058] Laser is used for local heavy doping to reduce the contact resistance at the ...

Embodiment 2

[0069] Embodiment 2: This embodiment provides a method for producing a monocrystalline silicon solar cell, the difference from Embodiment 1 is:

[0070] In this embodiment, the mixed solution is composed of dimethyl dodecyl amine oxide, palladium acetate, tri-tert-butylphosphine tetrafluoroborate and water, and the mixed solution includes each component in mass percentage: 10% dimethyl deca Dialkylamine oxide, 4% palladium acetate, 6% tri-tert-butylphosphine tetrafluoroborate, and 80% deionized water.

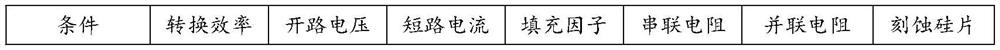

[0071] The etching solution activator in Example 2 can quickly activate the etching solution in the wet etching etch tank, shorten the activation time, and do not need to use a large number of silicon wafers to run the film to activate the etching solution. It can be directly produced after activating the etching solution, and the initial quality A 10g silicon wafer loses 0.30g in weight after etching, the reflectivity after back etching is 27.30%, and the conversion efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com