Preparation method of precious metal anode for electrolytic copper foil

A technology of electrolytic copper foil and precious metals, applied in the electrolysis process, electroforming, etc., can solve the problems of abnormal anode failure, titanium substrate oxidation, high current density, etc., and achieve the effects of inhibiting titanium substrate passivation, uniform dispersion, and reducing voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the preparation method of the noble metal anode for electrolytic copper foil provided by the present invention, the coating of the titanium anode is an Ir-Ta system noble metal coating containing a platinum intermediate layer, and the specific preparation steps are as follows:

[0040] S1. Pretreatment of the surface of the titanium substrate:

[0041] S1.1. Perform surface degreasing and sandblasting on the titanium substrate;

[0042] S1.2. Carry out thermal correction treatment to the titanium substrate after sandblasting;

[0043] S1.3. Soak the corrected titanium substrate in dilute hydrochloric acid with a concentration of 3-15% for 8-24 hours, and then boil it in an oxalic acid solution with a concentration of 5-10% for 0.5-3 hours;

[0044] S1.4, cleaning and drying the titanium substrate;

[0045] S2. Preparation of primer solution A: Accurately weigh a certain amount of tantalum ethoxide solution and dissolve it in n-butanol solvent, stir at room temperat...

Embodiment 1

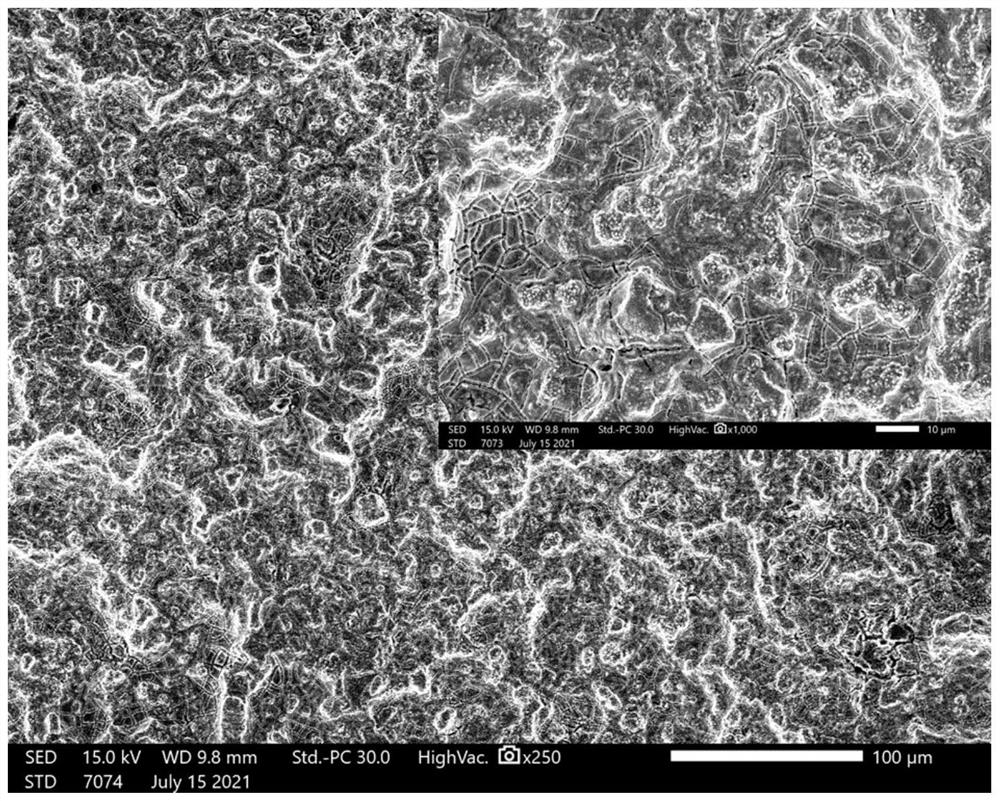

[0049] The scanning electron microscope image of the electrolytic copper foil anode prepared by the method of preparing the noble metal anode for electrolytic copper foil in this example can be found in figure 1 , the coating of the titanium anode is to add an Ir-Ta system noble metal coating containing a platinum intermediate layer, and the preparation method specifically includes:

[0050] S1. Pretreatment of the surface of the titanium substrate:

[0051] S1.1. Perform surface degreasing and sandblasting on the titanium substrate;

[0052] S1.2. Carry out thermal correction treatment to the titanium substrate after sandblasting;

[0053] S1.3. Soak the titanium matrix with the corrected shape in dilute hydrochloric acid with a concentration of 3-15% for 8-24 hours, and then boil it in an oxalic acid solution with a concentration of 5-10% for 0.5-3 hours;

[0054] S1.4, cleaning and drying the titanium substrate;

[0055] S2. Preparation of primer solution A: Accurately w...

Embodiment 2

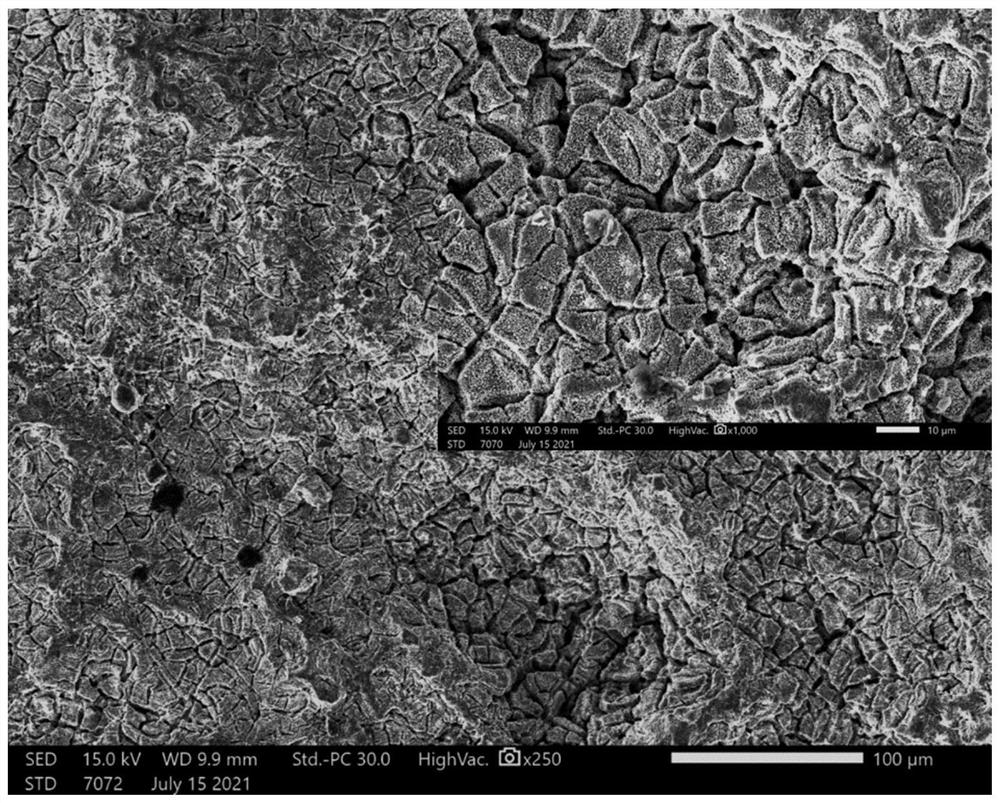

[0059] The scanning electron microscope image of the electrolytic copper foil anode prepared by the method of preparing the noble metal anode for electrolytic copper foil in this example can be found in figure 2 , the coating of the titanium anode is to add an Ir-Ta system noble metal coating containing a platinum intermediate layer, and the preparation method specifically includes:

[0060] S1. Pretreatment of the surface of the titanium substrate:

[0061] S1.1. Perform surface degreasing and sandblasting on the titanium substrate;

[0062] S1.2. Carry out thermal correction treatment to the titanium substrate after sandblasting;

[0063] S1.3. Soak the titanium matrix with the corrected shape in dilute hydrochloric acid with a concentration of 3-15% for 8-24 hours, and then boil it in an oxalic acid solution with a concentration of 5-10% for 0.5-3 hours;

[0064] S1.4, cleaning and drying the titanium substrate;

[0065] S2. Preparation of primer solution A: Accurately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com