Zinc oxide/cotton stalk biomass carbon composite material, and preparation method and application thereof

A technology of biomass carbon and composite materials, applied in the field of composite materials, can solve problems such as environmental pollution and resource waste, and achieve the effects of improving catalytic efficiency, improving utilization rate and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

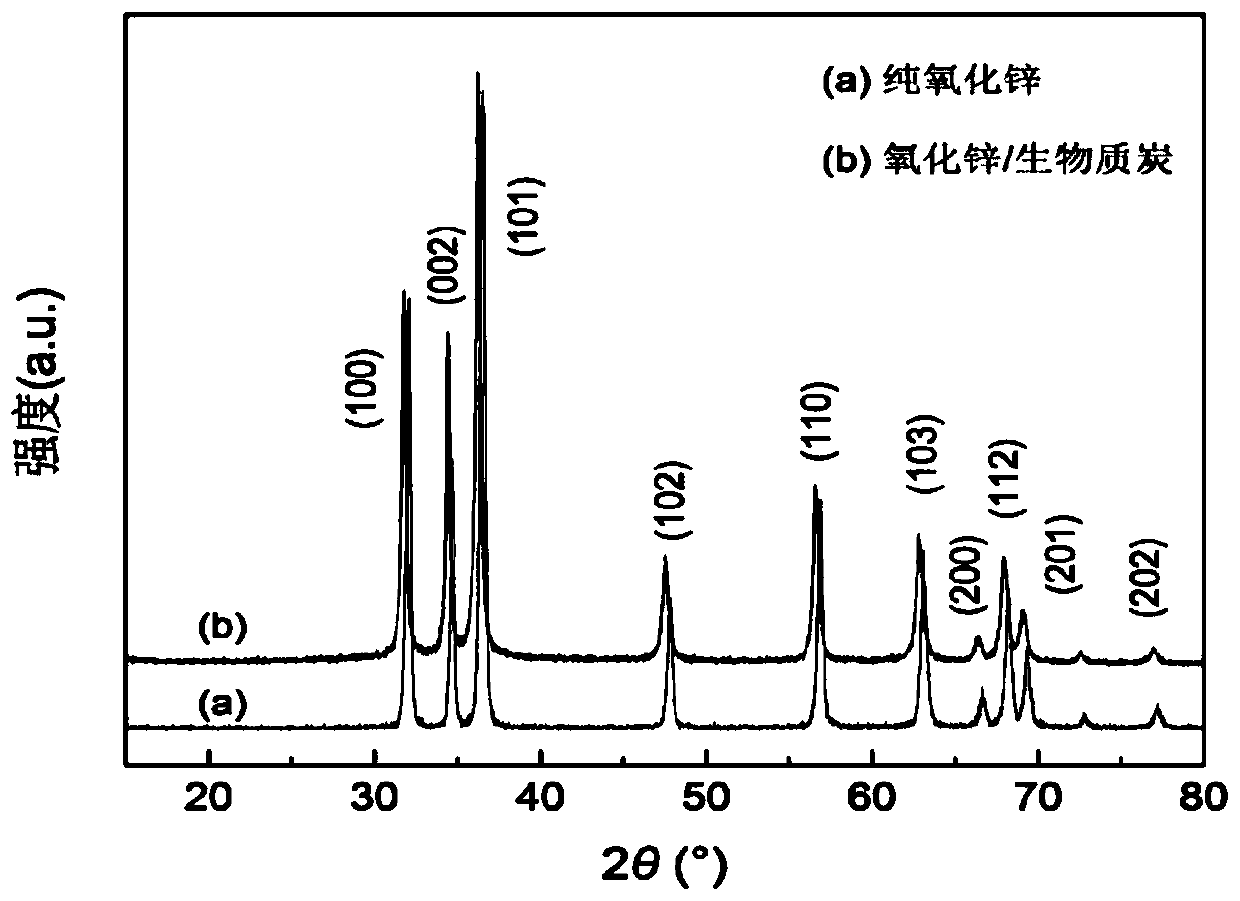

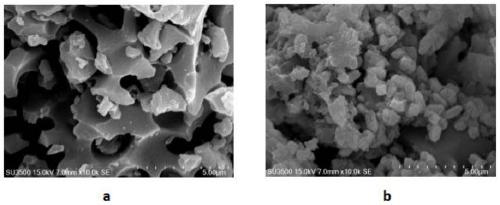

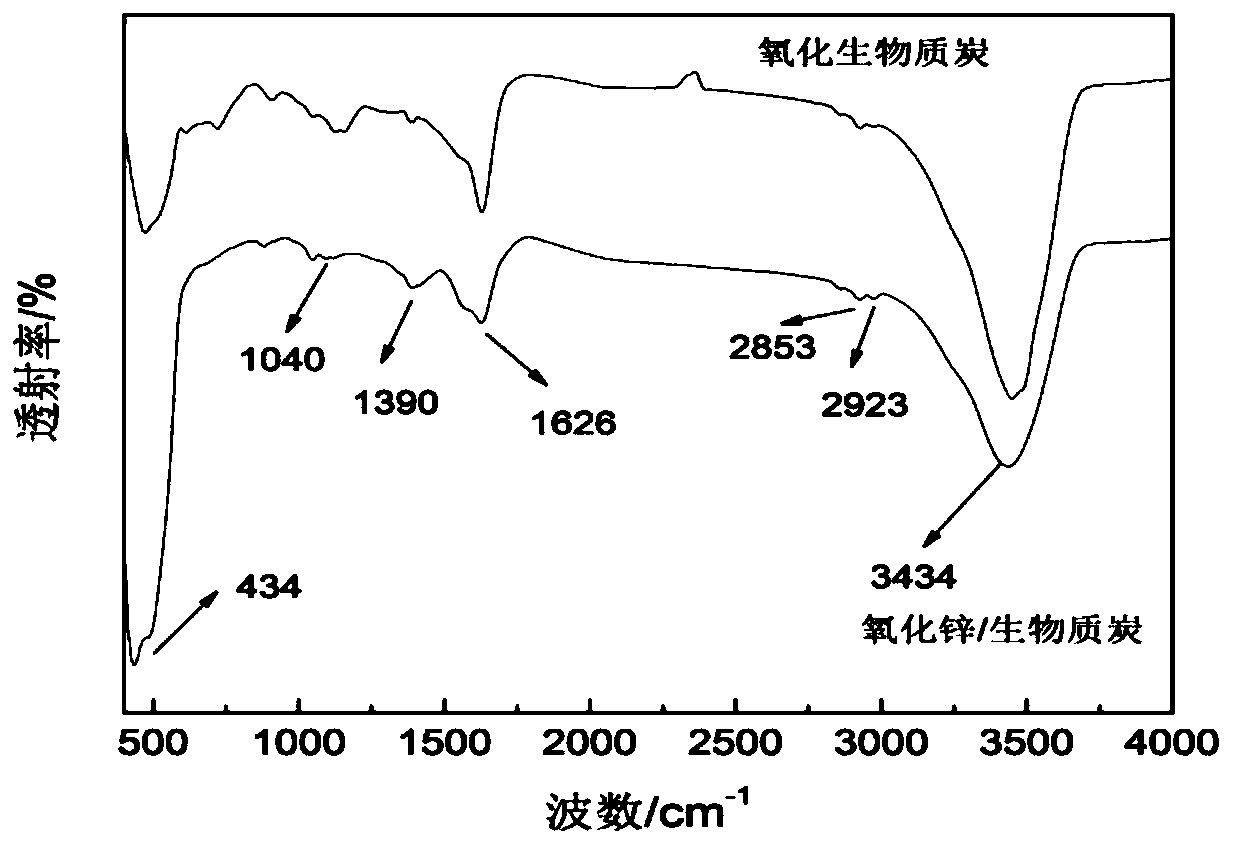

[0032] The invention provides a method for preparing a zinc oxide / cotton stalk biochar composite material, comprising the following steps:

[0033] (1) mixing cotton stalks, activator and water, drying and calcining in sequence to obtain biochar;

[0034] (2) Mixing the biochar, concentrated sulfuric acid, potassium permanganate, hydrogen peroxide and water for oxidation reaction to obtain oxidized biochar;

[0035] (3) Mix the oxidized biomass charcoal and water for ultrasonic treatment, then mix with the zinc source solution, adjust the pH value of the mixed solution to alkaline, and then carry out coprecipitation reaction to obtain a composite material precursor;

[0036] (4) Calcining the composite material precursor to obtain a zinc oxide / cotton stalk biochar composite material.

[0037] The invention mixes cotton stalks, an activator and water, and sequentially performs drying and calcining to obtain biochar. Before mixing, in the present invention, the cotton stalks a...

Embodiment 1

[0051] (1) Crush and sieve the cotton stalks, take 5g of crushed cotton stalks and 2g of potassium hydroxide, put them in a 500mL beaker, add 100mL of distilled water, stir with a glass rod until the alkali is completely dissolved, and place in a blast dryer , the temperature was set at 100°C, and dried; the dried substance was taken out and put into a crucible, and calcined in a box-type electric furnace at 500°C for 4 hours; the calcined substance was rinsed with 1mol / L dilute hydrochloric acid, and filtered drying to obtain biochar;

[0052] (2) Take a 500mL beaker, add 50mL of concentrated sulfuric acid, then add 1g of biomass charcoal, 7g of potassium permanganate in turn, magnetically stir for 2 hours, then add 250mL of distilled water in turn under the condition of continuous stirring, 20mL of mass concentration to 30% hydrogen peroxide, stop stirring; take it out after standing for 12 hours, pour off the supernatant, wash with distilled water 3 times, strengthen the al...

Embodiment 2

[0056] The mass of the oxidized biochar in step (3) of Example 1 was changed to 0.05 g, and the rest of the operation methods were kept unchanged to obtain the zinc oxide / cotton stalk biochar composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com