Method for extracting gold from electronic waste

An electronic waste and alloy technology, applied in the field of gold extraction, can solve the problems of difficulty in obtaining purity, strict equipment requirements, and great environmental hazards, and achieve the effect of good separation and purification effect, low equipment requirements, and small environmental hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]1) Raw material pretreatment: Treat gold-containing waste (such as waste CPU, memory, etc.) with 15% nitric acid, or a mixed acid of 10% nitric acid and 10% sulfuric acid, to dissolve other metals and impurities, so that gold is further enriched. The gold-plated layer or other gold-containing parts will gradually separate from the substrate. After other metals (such as copper, nickel, tin, iron, magnesium, aluminum, zinc, lead, etc.) and impurities are fully dissolved, gold will be further enriched. Filter, wash the filter residue with deionized water, and use the gold-containing filter residue with a higher enrichment degree for later use. The purpose of pretreatment is to further enrich gold, reduce volume and reduce impurities for a wide variety of electronic components, which is convenient for subsequent purification operations.

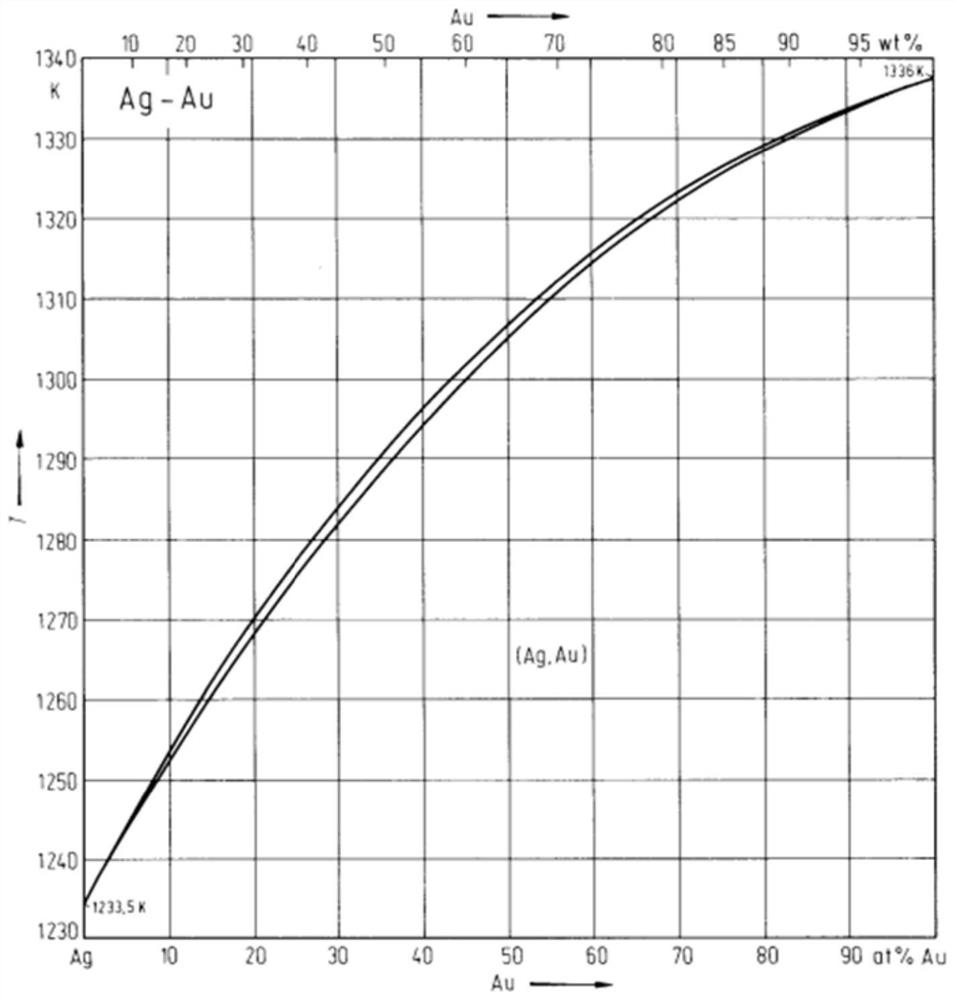

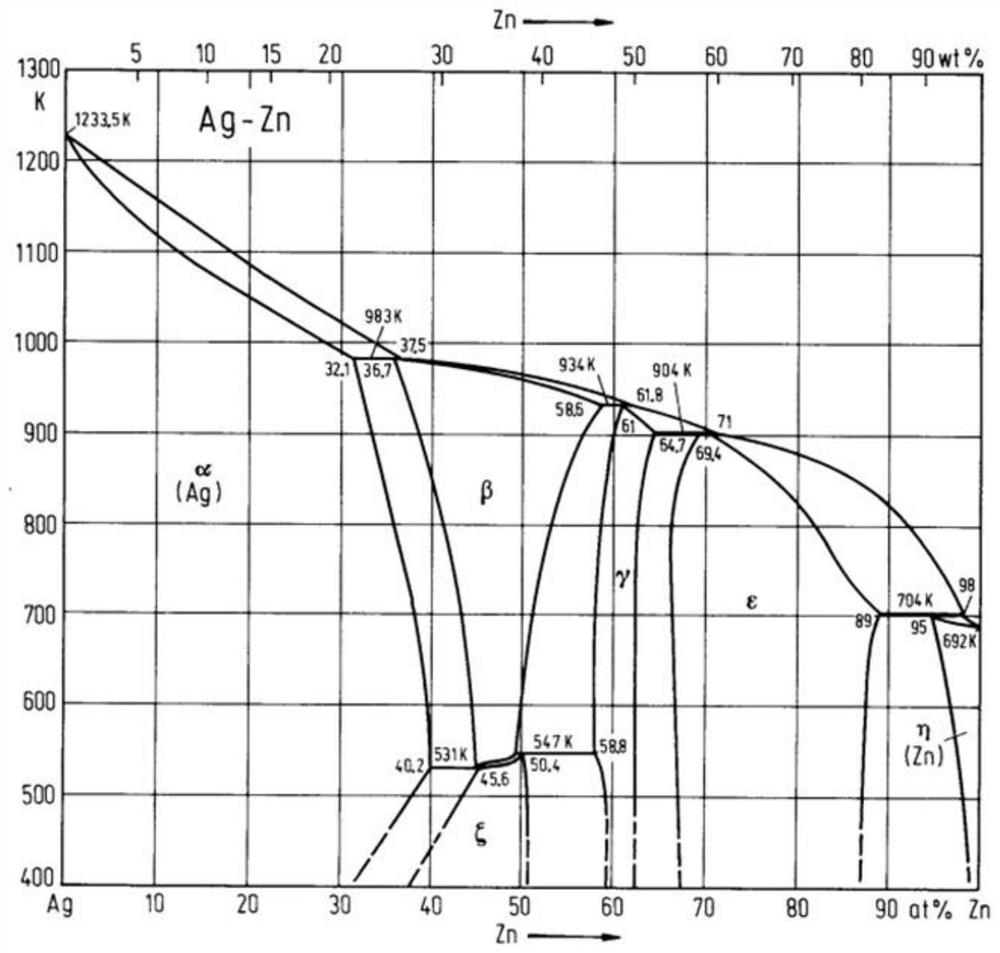

[0050] 2) For the gold-containing filter residue with a total gold content of about 2g, mix the filter residue with 6.0g pure silver (Ag) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com