Gas-based shaft furnace direct reduction method for hydrocarbon-rich gas and reduction system thereof

A gas-based shaft furnace and shaft furnace technology, which is applied to shaft furnaces, furnaces, furnace types, etc., can solve the problems of large investment, high outlet temperature of transition section, and complicated installation, and achieve the effect of reducing investment and reducing overall investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

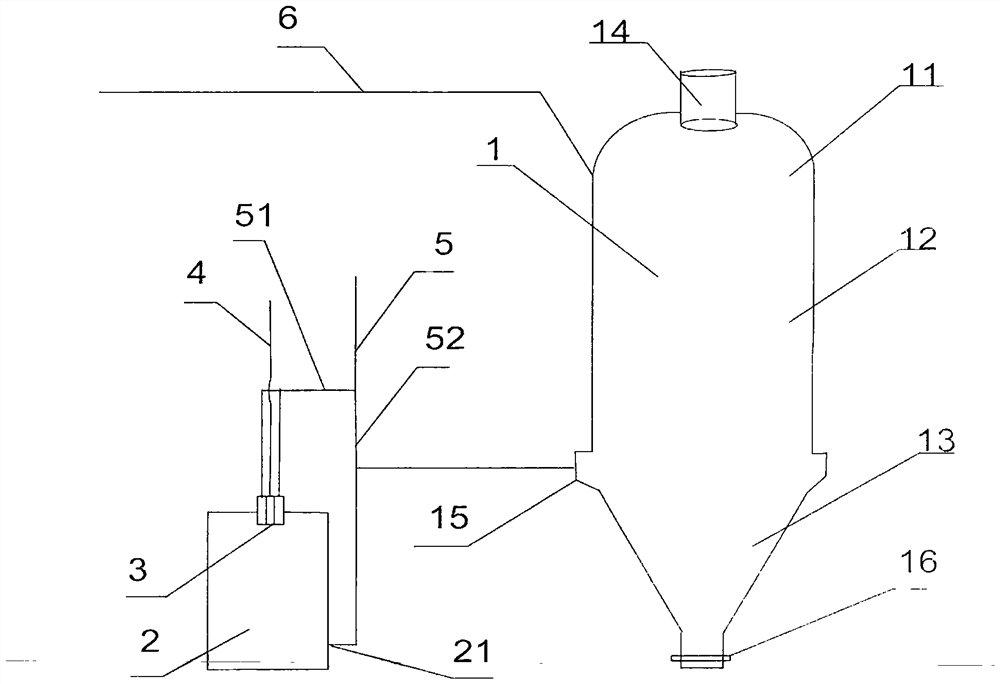

[0048] see figure 1 . Natural gas is used as the hydrocarbon-rich gas. Iron oxides with a particle size of 8-16 mm are fed into the gas-based shaft furnace 1 from a furnace top charging device 14 . The hydrocarbon-rich gas main pipe 5 leads to two branch pipes, and the oxygen 4 and the hydrocarbon-rich gas in the first branch pipe 51 pass into the burner 3 in the reformer 2, and the volume ratio of the oxygen 4 to the hydrocarbon-rich gas is about 70%. The pressure in the oxidation reformer 2 is 0.5Mpa, oxygen 4 and hydrocarbon-rich gas are anoxic and combusted in the reformer to generate H 2 and CO, at reformer 2 outlet line 21, the gas reaches 1350°C. Inject the unheated hydrocarbon-rich gas through the second branch pipeline 52 of the hydrocarbon-rich gas into the outlet pipeline 21 of the reformer 2 whose gas temperature reaches 1350° C. to form a mixed gas. The hydrocarbon-rich gas first branch pipe 51 and the second branch pipe 52 The internal flow ratio is about 2-3...

Embodiment 2

[0050] see figure 2 . The hydrocarbon-rich gas is coke oven gas. Iron oxides with a particle size of 8-16 mm are fed into the gas-based shaft furnace 1 from a furnace top charging device 14 . The hydrocarbon-rich gas main pipe 5 leads to two branch pipes, the oxygen 4 and the hydrocarbon-rich gas in the first branch pipe 51 pass into the burner 3 in the reformer 2, and the water vapor passes through the steam main pipe 7 into the outer ring channel of the burner 3 , the volume ratio of oxygen 4 to hydrocarbon-rich gas is about 28%, and the pressure in partial oxidation reformer 2 is 0.7Mpa. Oxygen 4 and hydrocarbon-rich gas burn anoxic in the reformer to generate H 2 and CO, at reformer 2 outlet line 21, the gas reaches 1200°C. Inject the unheated hydrocarbon-rich gas through the second branch pipeline 52 of the hydrocarbon-rich gas into the outlet pipeline 21 of the reformer 2 whose gas temperature reaches 1200°C to form a mixed gas. The hydrocarbon-rich gas first branch ...

Embodiment 3

[0052] see image 3 . The hydrocarbon-rich gas is coalbed methane. Iron oxides with a particle size of 8-16 mm are fed into the gas-based shaft furnace 1 from a furnace top charging device 14 . The hydrocarbon-rich gas main pipe 5 leads to two branch pipes. The oxygen 4 and the hydrocarbon-rich gas in the first branch pipe 51 are passed into the burner 3 in the reformer 2. The volume ratio of the oxygen 4 to the hydrocarbon-rich gas is about 65%. The pressure in the oxidation reformer 2 is 0.1Mpa, oxygen 4-5 and hydrocarbon-rich gas are anoxic and combusted in the reformer to generate H 2 and CO, at reformer 2 outlet line 21, the gas reaches 1200°C. The steam in the steam main pipe 7 is passed into the second branch pipeline 52 of the rich hydrocarbon gas, and then the mixed gas of the steam and the rich hydrocarbon gas is injected into the reformer 2 outlet pipeline 21 to form a new mixed gas, and the rich hydrocarbon gas is The flow ratio in the first branch pipe 51 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com