Nanofiltration membrane for extracting lithium from salt lake as well as preparation method and application of nanofiltration membrane

A nanofiltration membrane and filter membrane technology, applied in the field of nanofiltration membranes and their preparation, can solve the problems of reducing the adsorption capacity and adsorption rate of lithium ion sieves, hindering the industrial application of lithium ion sieve membranes, and damaging powders, etc., and achieve excellent retention. performance, achieving industrialized mass production, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

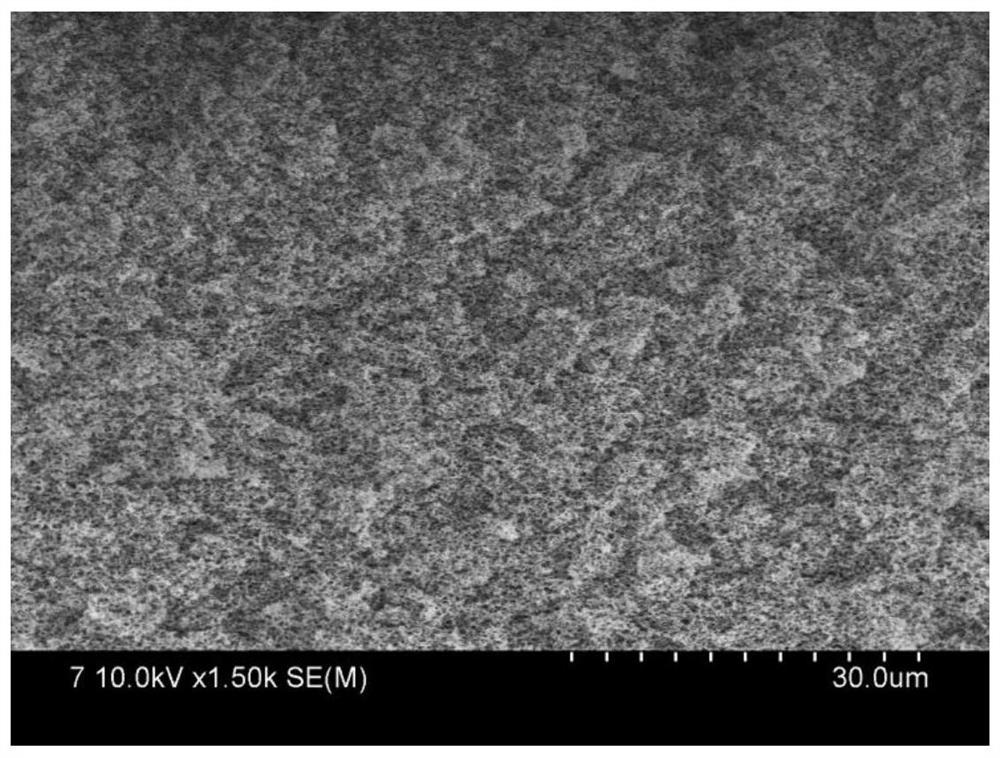

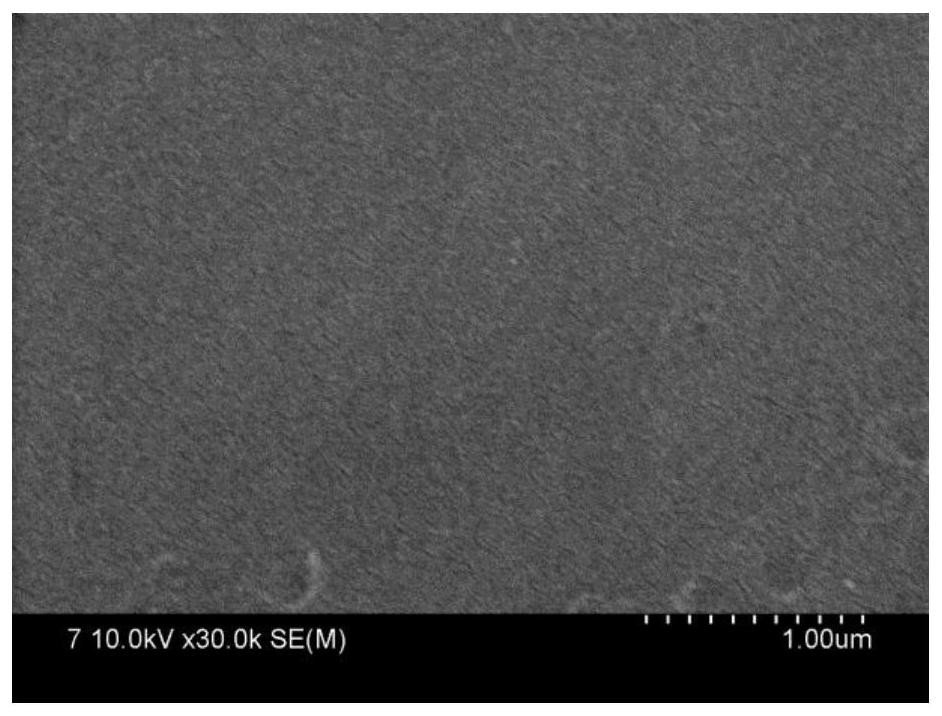

[0049] (1) Dry the polyimide polymer at 120°C, remove water for later use; dissolve 20wt% polyimide in N-methylpyrrolidone, stir and dissolve at 100°C for 6h, and wait for the polyimide After stirring and dissolving the raw materials completely, add 20wt% aminated silica nanoparticles, continue stirring and dissolving for 5 hours to obtain a uniform casting solution, stand for defoaming, and scrape the film to obtain an aminated silica modified with a loose porous structure. Polyimide polymer film;

[0050] (2) Configure a 500nm titanium-based lithium ion sieve solution with a concentration of 5wt%, fix the titanium-based lithium ion sieve in the membrane pores of the support layer by dead-end filtration, and obtain the titanium oxide lithium ion sieve in the loose porous support layer Aminated silica-modified polyimide nanofiltration membrane.

Embodiment 2

[0052] (1) Dry the polyimide polymer at 120°C, remove water for later use; dissolve 16wt% polyimide in N,N-dimethylformamide, stir and dissolve at 60°C for 3 hours, and wait for After the polyimide raw material is stirred and dissolved completely, add 15wt% aminated silicon dioxide nanoparticles, continue stirring and dissolving for 3 hours to obtain a homogeneous casting solution, leave it to defoam and scrape the film to obtain an aminated silicon dioxide with a loose porous structure. Silicon oxide modified polyimide polymer film;

[0053] (2) Configure a 300nm titanium-based lithium ion sieve solution with a concentration of 1wt%, fix the titanium-based lithium ion sieve in the membrane pores of the support layer by dead-end filtration, and obtain a porous support layer containing titanium oxide lithium ion sieve Aminated silica-modified polyimide nanofiltration membrane.

Embodiment 3

[0055] (1) Dry the polyimide polymer at 120°C, remove water for later use; dissolve 24wt% polyimide in N,N-dimethylacetamide, stir and dissolve at 120°C for 12h, and wait After the polyimide raw material is stirred and dissolved completely, add 25wt% aminated titanium dioxide nanoparticles, and continue stirring and dissolving for 6 hours to obtain a uniform casting solution. After standing for defoaming and scraping the film, an aminated titanium dioxide modified polyimide with a loose and porous structure is obtained. Polyimide polymer film;

[0056] (2) Configure a 2 μm titanium-based lithium ion sieve solution with a concentration of 10 wt%, fix the titanium-based lithium ion sieve in the membrane pores of the support layer by dead-end filtration, and obtain a porous support layer containing titanium oxide lithium ion sieve. Aminated titanium dioxide modified polyimide nanofiltration membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com