Method for flue gas denitration by using hydrogen peroxide and manganese dioxide

A manganese dioxide and hydrogen peroxide technology is applied in the field of flue gas denitrification, which can solve the problems of poor denitrification effect by oxidation method, and achieve the effects of novel process design, improved removal effect and good denitration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

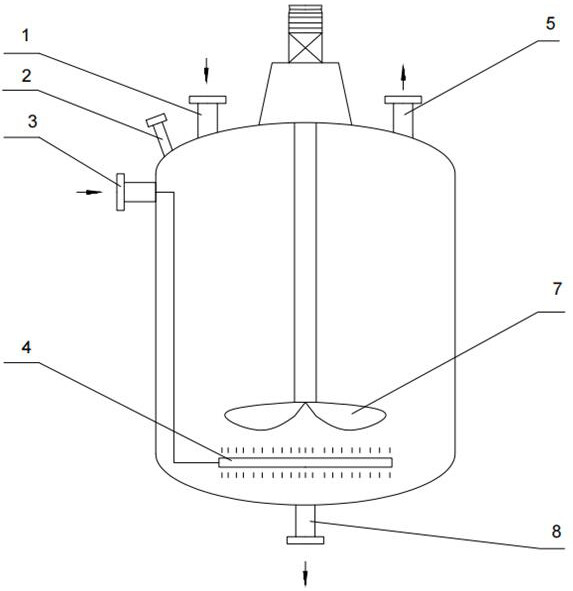

[0030] Such as figure 1 As shown, this embodiment provides the specific steps of the method for using hydrogen peroxide and manganese dioxide to denitrify flue gas.

[0031] (1) Dilute the hydrogen peroxide with a mass ratio of 35% to 3%;

[0032] (2) Take 100kg of hydrogen peroxide from step (1) and put it into a stirred reactor through the liquid inlet 1. The structure diagram of the stirred reactor is as follows figure 1 , the volume of the stirred reactor is 200 liters, and the stirrer 7 of the stirred reactor is a propulsive stirrer, and a gas distributor 4 is arranged at the lower position of the stirrer 7, and the gas distributor 4 is connected with the gas inlet 3 of the stirred reactor, The upper part of the stirred reactor is provided with a gas outlet 5, a liquid inlet 1, and a powder inlet 2, and the bottom of the stirred reactor is provided with a liquid outlet 8;

[0033] (3) Start the stirring reaction kettle, the rotating speed of the stirrer is 20r / min, and ...

Embodiment 2

[0040] Such as figure 1 As shown, this embodiment provides the specific steps of the method for using hydrogen peroxide and manganese dioxide to denitrify flue gas.

[0041] (1) Dilute the hydrogen peroxide with a mass ratio of 35% to 1% with water;

[0042] (2) Take 100kg of hydrogen peroxide from step (1) and put it into a stirred reactor through the liquid inlet 1. The structure diagram of the stirred reactor is as follows figure 1 , the volume of the stirred reactor is 200 liters, and the stirrer 7 of the stirred reactor is a propulsive stirrer, and a gas distributor 4 is arranged at the lower position of the stirrer 7, and the gas distributor 4 is connected with the gas inlet 3 of the stirred reactor, The upper part of the stirred reactor is provided with a gas outlet 5, a liquid inlet 1, and a powder inlet 2, and the bottom of the stirred reactor is provided with a liquid outlet 8;

[0043] (3) Start the stirring reactor, the rotating speed of the stirrer is 50r / min, a...

Embodiment 3

[0050] Such as figure 1 As shown, this embodiment provides the specific steps of the method for using hydrogen peroxide and manganese dioxide to denitrify flue gas.

[0051] (1) Dilute the hydrogen peroxide with a mass ratio of 35% to 1.8% with water;

[0052] (2) Take 100kg of hydrogen peroxide from step (1) and put it into a stirred reactor through the liquid inlet 1. The structure diagram of the stirred reactor is as follows figure 1 , the volume of the stirred reactor is 200 liters, and the stirrer 7 of the stirred reactor is a propulsive stirrer, and a gas distributor 4 is arranged at the lower position of the stirrer 7, and the gas distributor 4 is connected with the gas inlet 3 of the stirred reactor, The upper part of the stirred reactor is provided with a gas outlet 5, a liquid inlet 1, and a powder inlet 2, and the bottom of the stirred reactor is provided with a liquid outlet 8;

[0053] (3) Start the stirring reaction kettle, the rotating speed of the stirrer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com