Desulfurization and denitrification process utilizing microwave to intermittently irradiate activated carbon

A microwave intermittent, desulfurization and denitrification technology, applied in the field of flue gas purification, can solve the problems of damaging catalytic activity, affecting the implementation of technology industrialization, and carbon loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

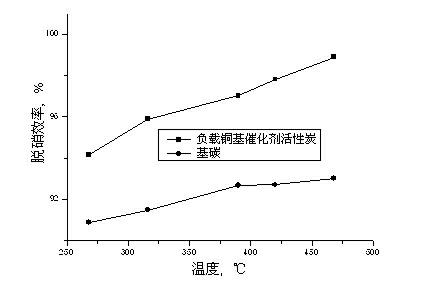

Embodiment 1

[0022] Example 1: Fully wash the activated carbon particles with deionized water to remove impurities on the surface, and then fully soak them in deionized water for 6 hours to remove impurity ions adsorbed by activated carbon; ② Weigh the corresponding mass of activated carbon 0.5% The copper oxide was loaded on activated carbon by equal volume impregnation method; ③. Vacuum dried at 100°C for 4h; ④. Continued to vacuum dry at 120°C for 5h;

Embodiment 2

[0023] Example 2: Fully wash the activated carbon particles with deionized water to remove impurities on the surface, and then fully soak them in deionized water for 2 hours to remove impurity ions adsorbed by activated carbon; ② Weigh the corresponding mass of activated carbon 1% The copper oxide was loaded on activated carbon by equal volume impregnation method; ③. Vacuum dried at 100°C for 4h; ④. Continued to vacuum dry at 120°C for 5h;

Embodiment 3

[0024] Example 3: Fully wash the activated carbon particles with deionized water to remove impurities on the surface, and then fully soak them in deionized water for 4 hours to remove impurity ions adsorbed by activated carbon; ②Weigh the corresponding mass of activated carbon 5% Manganese oxide was loaded on activated carbon by equal volume impregnation method; ③. Vacuum dried at 85°C for 4h; ④. Continued to vacuum dry at 110°C for 8h.

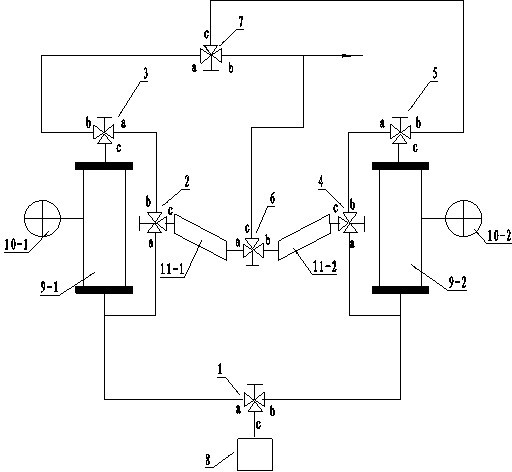

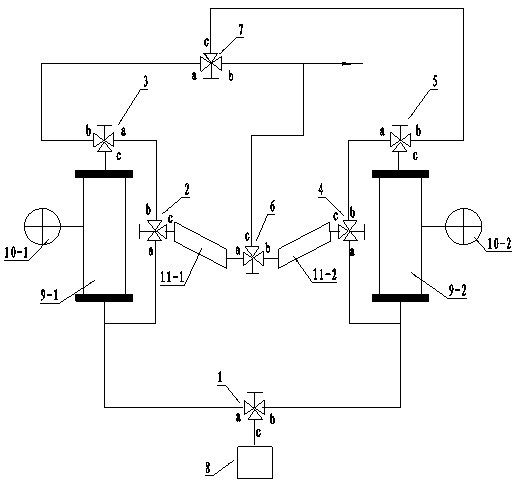

[0025] see figure 1 , The device for implementing the method of the present invention includes two activated carbon adsorption beds with microwave generators, two sulfur absorption pools, connecting pipelines and several three-way valves. The activated carbon particles of the above-mentioned examples of supported catalysts were placed in each adsorption bed. A first microwave generator 10-1 is provided next to the first adsorption bed 9-1, and a first sulfur recovery tank 11-1 is attached; a second microwave generator 10-2 is arranged nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com