Preparation method of penicillium group compounded cellulose synergistic degradation compound enzyme

A technology of synergistic degradation and cellulose, applied in the field of microorganisms, to improve the degradation efficiency, reduce the amount of added enzymes, and improve the efficiency of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of compound enzyme combination preparation with synergistic cellulose degradation

[0027] A method for preparing a compound enzyme of penicillium flora to synergistically degrade cellulose, comprising the following steps:

[0028] 1. Medium:

[0029] PDA liquid medium: Weigh 200g of peeled potatoes, add water to boil, filter through gauze to obtain potato juice, then add 20g of glucose, dissolve and add water to 1L, pH value is natural, sterilized at 115°C for 30min, and made into grade one Seed medium.

[0030] Solid-state fermentation medium: composed of 5g rice straw and 10.5mL nutrient salt solution, the composition of nutrient salt solution is: each liter of nutrient salt solution contains (NH 4 ) 2 SO 4 10.0g, KH 2 PO 4 4.0g, MgSO 4 ·7H 2 O 0.5g, CaCl 22H 2 O 0.5g, the balance is 1000mL water. The initial pH was adjusted to 6 (adjusted with 1M NaOH), and sterilized at 115°C for 30 minutes to make a solid-state fermentation medi...

Embodiment 2

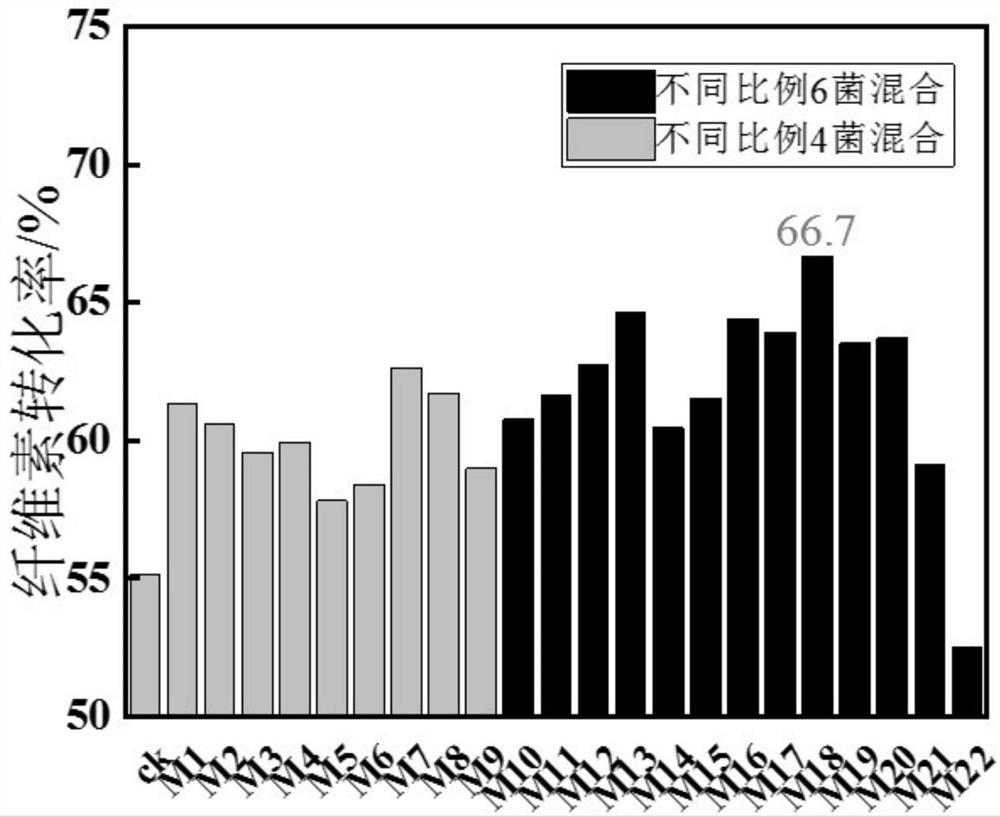

[0045] Example 2: Compound enzyme combination preparation applied to enzymatic hydrolysis of poplar wood cellulose

[0046] 1. Reaction substrate: crush poplar to 60 mesh, dry at 105°C to constant weight, accurately weigh (10g) poplar into a pressure bottle, first add 0.5% v / v sulfuric acid solution to make the solid-liquid ratio 1 :20(g:L), use a sterilizer for 1 hour at 121°C. After the pretreatment, use a G3 sand core funnel to separate the mixture from solid to liquid, then wash the residue with deionized water to a neutral pH value, and dry it in an oven at 105°C to constant weight; then weigh the acid pretreated bottom Add 2% w / v sodium hydroxide solution to make the solid-to-liquid ratio 1:20 (g:L), and use a sterilizing pot to treat at 121°C for 1h. After pretreatment, use G3 sand core funnel to separate the mixture from solid to liquid, then wash the residue with deionized water to a neutral pH value, place it in an oven at 105°C and dry it to constant weight, and fi...

Embodiment 3

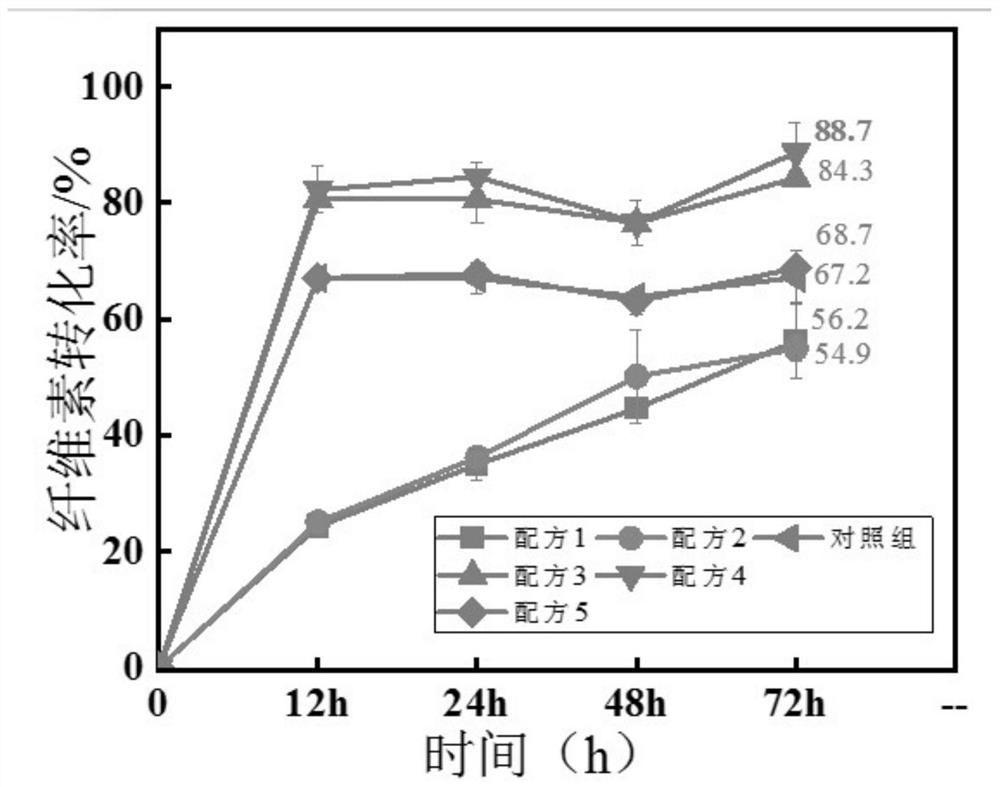

[0049] Embodiment 3: Comparison of different enzymolysis formulations

[0050] The poplar wood with acid-base composite pretreatment was prepared according to the method of Example 2.

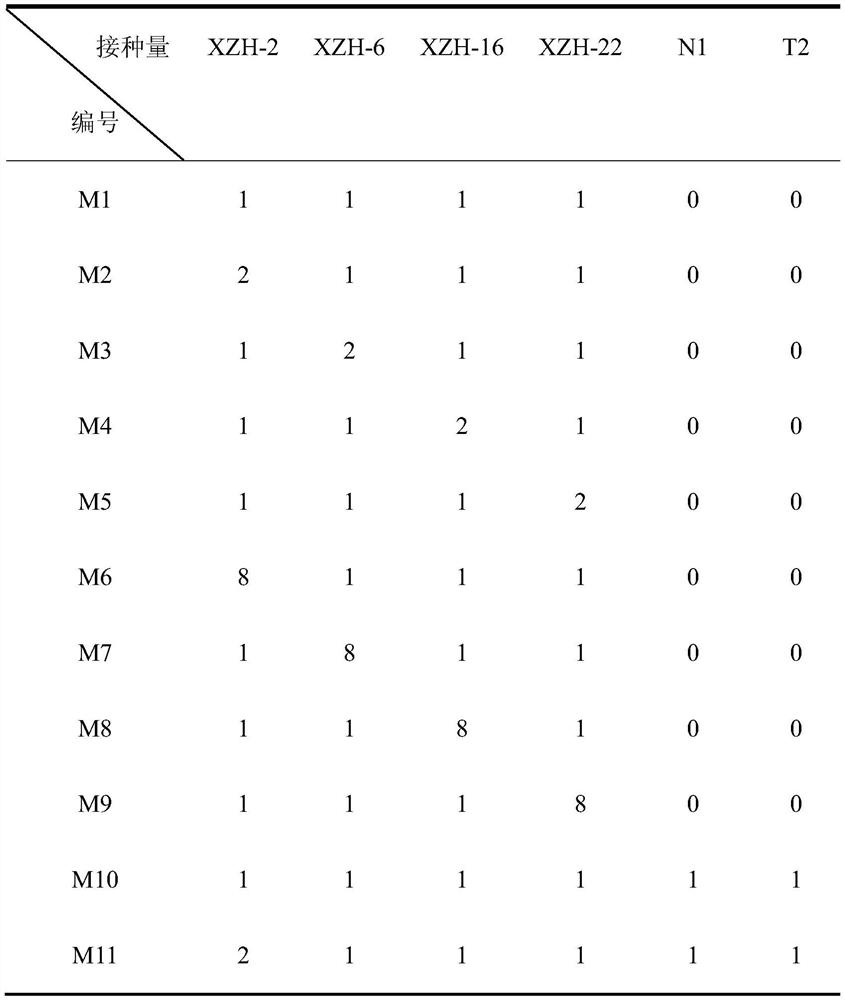

[0051] Take 0.1g poplar pretreated by acid-base compound, and carry out enzymatic hydrolysis in 5mL different solution formulation systems. Among them, formula 1: do not add CTec2 cellulase, M1 compound enzyme combination preparation, protein amount 40 mg, make up 5 mL with acetic acid-sodium acetate buffer solution with a concentration of 0.2M and pH=4.8; formula 2: do not add CTec2 cellulase , M18 compound enzyme combination preparation, the amount of protein is 40mg, supplement 5mL with acetic acid-sodium acetate buffer solution with a concentration of 0.2M and pH=4.8; formula 3: CTec2 cellulase 10FPU / g substrate, M1 compound enzyme combination preparation, protein Amount 40mg, make up 5mL with acetic acid-sodium acetate buffer solution with a concentration of 0.2M and pH=4.8; formula 4: CT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com