Efficient preparation method of sulfur halide compound solid electrolyte

A solid electrolyte and compound technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of insoluble raw materials, long reaction time, low output, etc. The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

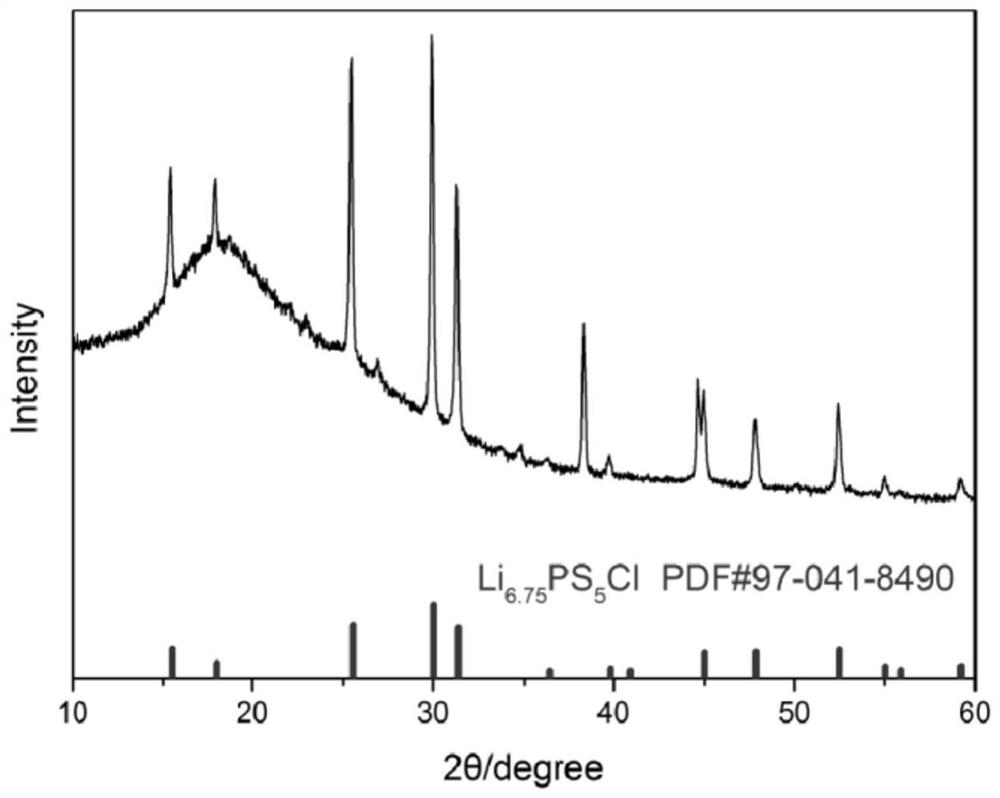

Embodiment 1

[0027] Weigh Li according to the stoichiometric ratio of 5:1:2 2 S, P 2 S 5 and LiCl, then Li 2 S, P 2 S 5 The mass ratio of the total mass of LiCl and the grinding medium is 1:3, and an appropriate amount of ethyl propionate is weighed, and it is successively packed into a zirconia vacuum ball mill jar, and simultaneously, zirconia ball milling beads are added at a ball-to-material ratio of 40:1. And fill it with argon gas of 0.15Mpa to carry out ball milling for 4 hours at a speed of 400r / min. Thereafter, the ball milling tank was evacuated and heated to 120° C. for a second ball milling for 8 hours at a rotational speed of 800 r / min. Thereafter, the ball mill jar was cooled and filled with 0.15Mpa argon to perform ball milling three times for 2 hours at a rotational speed of 300r / min. After the ball milling, the solid electrolyte precursor slurry was dried under the protection of an inert atmosphere at a temperature of 150° C. for 40 h. The dried solid electrolyte pr...

Embodiment 2

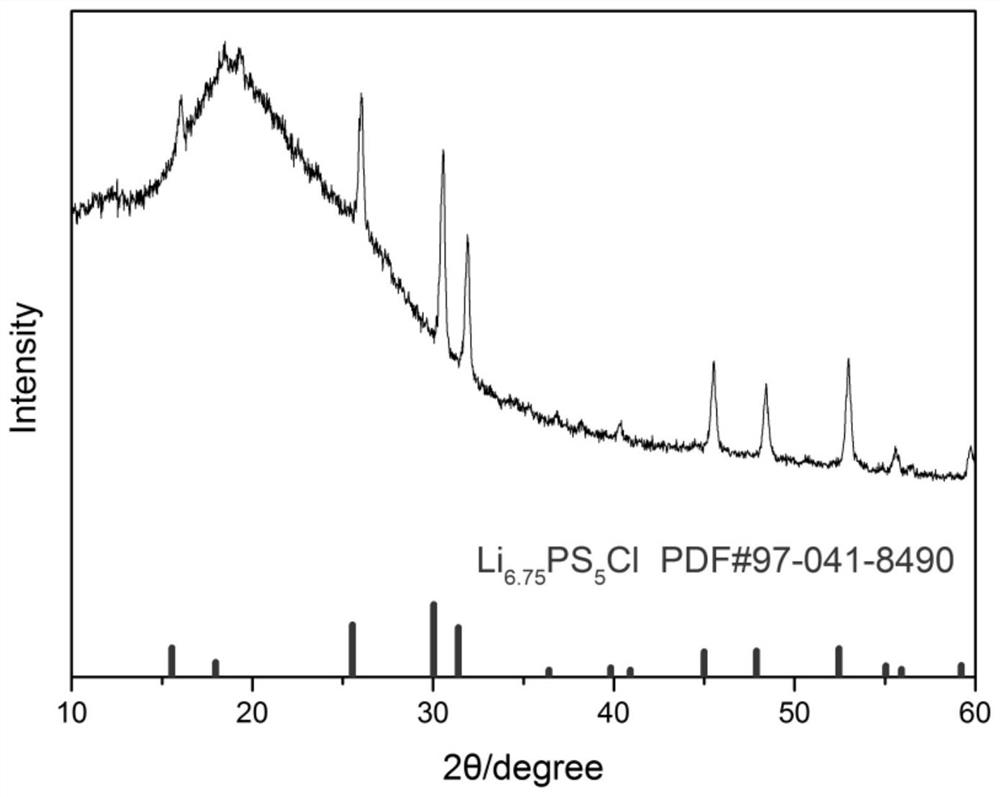

[0029] Weigh Li according to the stoichiometric ratio of 5:1:0.8:1.2 2 S, P 2 S 5 , LiCl and LiBr, then press Li 2 S, P 2 S 5 The mass ratio of the total mass of LiCl and LiBr to the grinding medium is 1:3. Weigh an appropriate amount of propylene oxide, put it into a zirconia vacuum ball milling tank in turn, and add zirconia ball milling beads at a ball-to-material ratio of 40:1 , and filled with argon gas of 0.15Mpa to carry out a ball milling, the time is 4h, the rotating speed is 400r / min. Thereafter, vacuumize the ball mill jar and heat it to 150° C. for a second ball mill for 8 hours at a rotational speed of 800 r / min. Thereafter, the ball mill jar was cooled and filled with 0.15Mpa argon to perform ball milling three times for 2 hours at a rotational speed of 300r / min. After the ball milling, the solid electrolyte precursor slurry was dried under the protection of an inert atmosphere at a temperature of 150° C. for 48 h. The dried solid electrolyte precursor was...

Embodiment 3

[0031] Weigh Li according to the stoichiometric ratio of 4.5:1:1.5:1 2 S, P 2 S 5 , LiCl and LiI, then press Li 2 S, P 2 S 5The mass ratio of the total mass of LiCl and LiI to the grinding medium is 1:4. Weigh an appropriate amount of octamethylcyclotetrasiloxane, and put it into a zirconia vacuum ball mill jar in turn, and press the ball-to-material ratio of 40:1 Add zirconia ball milling beads, and fill with argon gas of 0.15Mpa to carry out ball milling for 4 hours at a speed of 400r / min. Thereafter, vacuumize the ball mill jar and heat it to 150° C. for a second ball mill for 12 hours at a rotational speed of 800 r / min. Thereafter, the ball mill jar was cooled and filled with 0.15Mpa argon to perform ball milling three times for 2 hours at a rotational speed of 300r / min. After the ball milling, the solid electrolyte precursor slurry was dried under the protection of an inert atmosphere at a temperature of 150° C. for 36 h. The dried solid electrolyte precursor was s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com