A kind of Rayleigh scattering enhanced optical fiber and its preparation method

A technology of Rayleigh scattering and fabrication method, applied in cladding fiber, multi-layer core/cladding fiber, optics, etc., can solve the problems of enhanced fiber core scattering, limitation of measurable range, etc., to achieve low transmission loss, The effect of increasing Rayleigh scattering intensity, enhancing sensing accuracy and sensing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

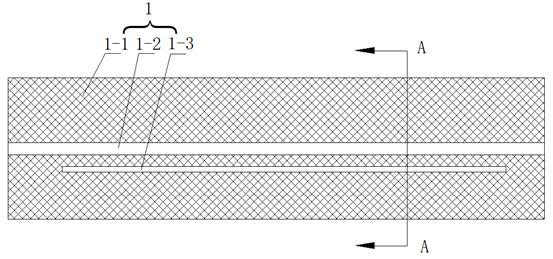

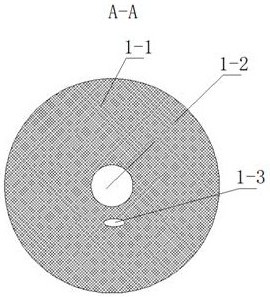

[0030] exist figure 1 , 2 Among them, a Rayleigh scattering-enhanced optical fiber in this embodiment has a waveguide 1-3 written on the cladding 1-1 of the single-core optical fiber 1 along the direction of the center line, and the waveguide 1-3 is parallel to the core 1-2. The distance between the waveguide 1-3 and the fiber core 1-2 is 6 μm, and the length of the waveguide 1-3 is 2 cm.

[0031] The manufacturing method of the Rayleigh scattering enhanced optical fiber of this embodiment consists of the following steps:

[0032] S1. Optical fiber pretreatment

[0033] First take a section of single-core optical fiber 1, clean the pre-prepared part of the optical fiber with alcohol, and use a fusion splicer to weld one end of the optical fiber to the jumper head of the single-mode optical fiber;

[0034] S2. Fiber Placement

[0035] Place the cleaned single-core optical fiber in step S1 on a glass slide, immerse the prepared part of the single-core optical fiber with a re...

Embodiment 2

[0044] In this embodiment, a Rayleigh scattering-enhanced optical fiber has a waveguide 1-3 written on the cladding 1-1 of the single-core optical fiber 1 along the direction of the center line, and the waveguide 1-3 is parallel to the core 1-2. The distance between the waveguide 1-3 and the fiber core 1-2 is 1.5 μm, and the length of the waveguide 1-3 is 2 cm.

[0045] In the manufacturing method of the Rayleigh scattering-enhanced optical fiber of this embodiment, steps S1 and S2 are the same as in embodiment 1. After the single-core optical fiber 1 is placed in step S3, the processing parameters are set in the software of the three-dimensional translation stage, that is, the pre-processed The length of the cladding waveguide is set to 2cm, the power of the femtosecond laser is set to 0.8μW, the repetition frequency is set to 200Hz, the wavelength of the femtosecond laser is 800nm, and the pulse width is 50fs. Adjust the focus position of the femtosecond laser so that the dia...

Embodiment 3

[0047] In this embodiment, a Rayleigh scattering-enhanced optical fiber has a waveguide 1-3 written on the cladding 1-1 of the single-core optical fiber 1 along the direction of the center line, and the waveguide 1-3 is parallel to the core 1-2. The distance between the waveguide 1-3 and the fiber core 1-2 is 10 μm, and the length of the waveguide 1-3 is 2 cm.

[0048] In the manufacturing method of the Rayleigh scattering enhanced optical fiber of this embodiment, steps S1 and S2 are the same as in embodiment 1. After the single-core optical fiber is placed in step S3, the processing parameters are set in the software of the three-dimensional translation stage, that is, the pre-processed package The length of the layer waveguide is set to 2cm, the power of the femtosecond laser is set to 2μW, the repetition rate is set to 500Hz, the wavelength of the femtosecond laser is 800nm, and the pulse width is 50fs. Adjust the focus position of the femtosecond laser so that the diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com