High-performance non-curing asphalt waterproof coating

A kind of asphalt waterproof coating, non-curing technology, applied in asphalt coating, fireproof coating, coating, etc., can solve the problems of poor product performance stability, large environmental pollution, high heating temperature, etc., achieve high product performance, simple and simple preparation method The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

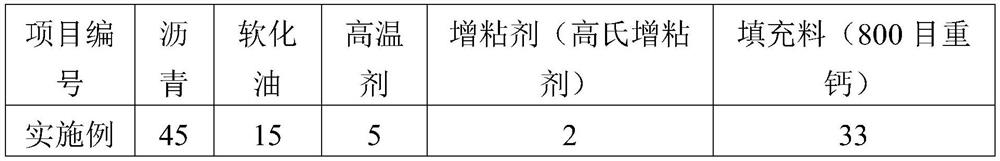

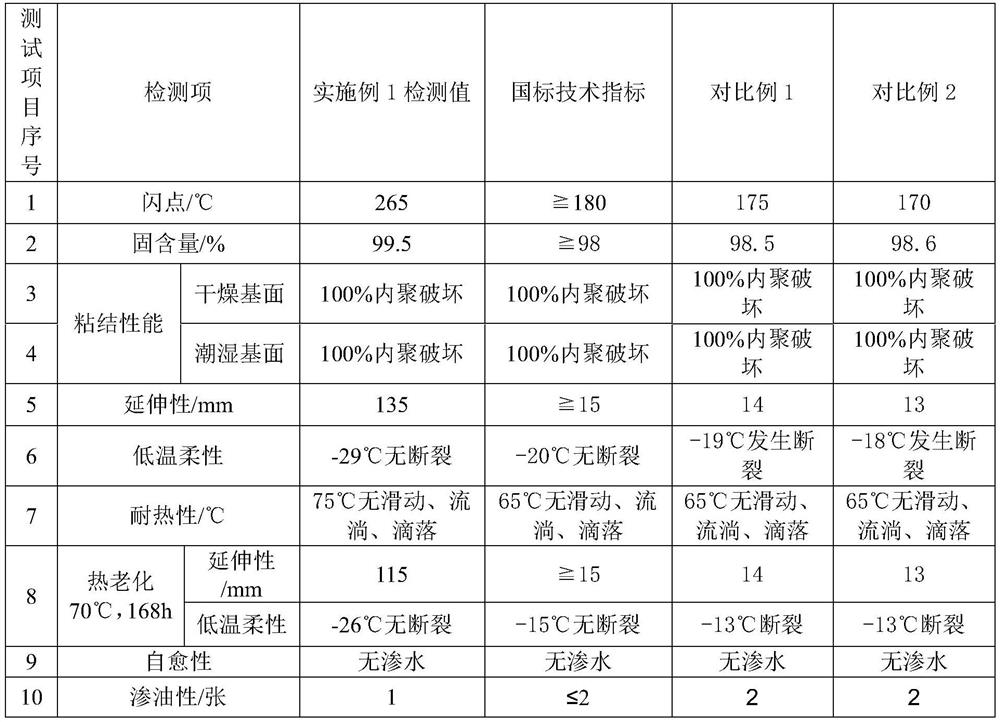

[0030] Each substance added in Examples 1 to 3 is added as shown in Table 1 below;

[0031] Table 1 (parts by weight)

[0032]

[0033]

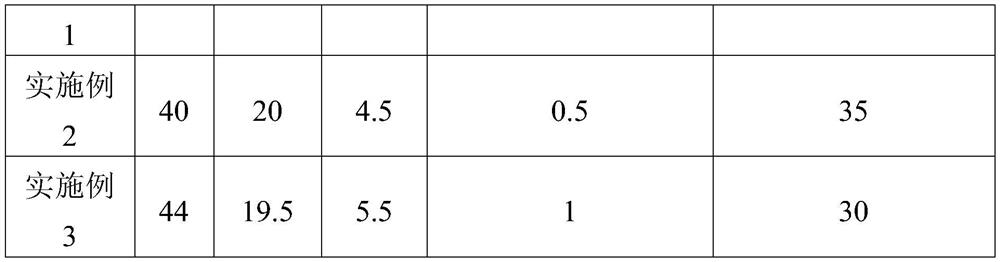

[0034] Table 2 (mass ratio)

[0035] Item Number thermoplastic styrene butadiene rubber powder polystyrene butadiene copolymer Example 1 1 0.6 Example 2 1 0.5 Example 3 1 1

[0036] Preparation method in embodiment 1~3 carries out according to the following steps:

[0037] 1. Calculated by 100 parts by weight: Weigh the asphalt and softened oil in turn, heat and melt, continue to heat to between 140°C and 150°C, and stir at 700rad / min for 15min;

[0038] 2. Slowly add the high-temperature agent, keep the temperature constant, stir at 700rad / min for 15min, then stir at 1000rad / min for 45min, observe whether the melting is complete, and proceed to the next step after no obvious particles

[0039] 3. Reduce the stirring to 700rad / min, add a thickener, and stir at 700rad / min for 30min;

[0040] 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com