Device and method for preparing micro powder by atomizing molten metal through ultrasonic standing wave array

A molten metal, ultrasonic standing wave technology, applied in the field of metal atomization micropowder preparation, can solve the problems of incomplete powder atomization, low energy utilization rate, low atomization efficiency, etc., and achieve high atomization efficiency and energy utilization rate , The effect of complete atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

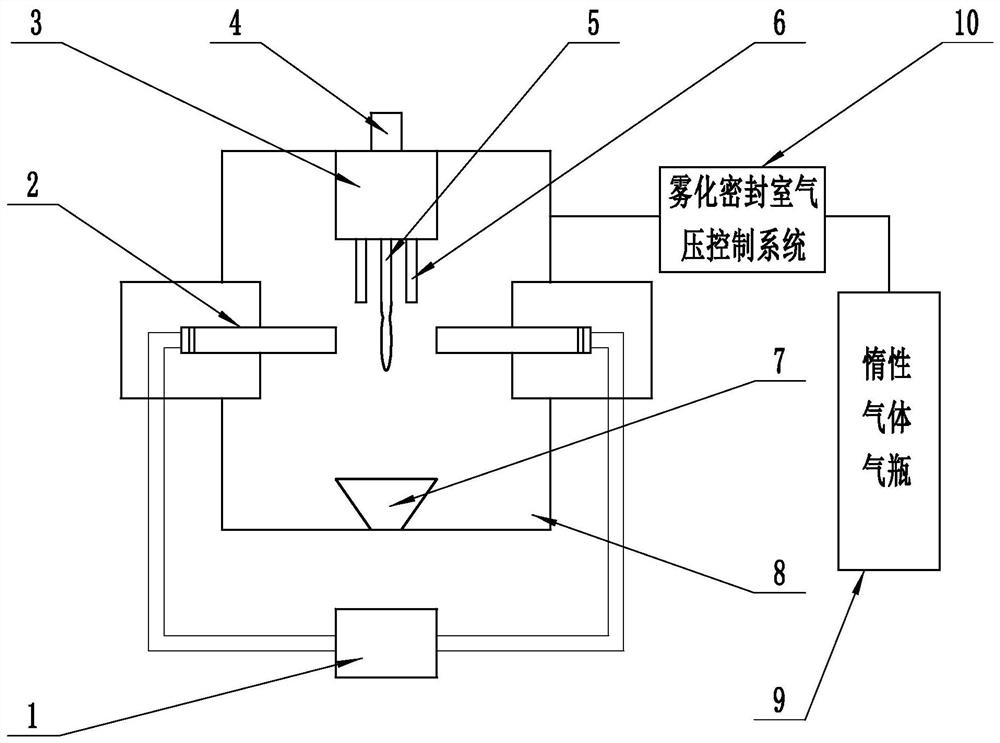

[0023] Specific implementation mode one: as Figure 1-Figure 3 As shown, this embodiment discloses a device for atomizing molten metal with an ultrasonic standing wave array for micropowder preparation, including an ultrasonic power supply 1, a high-temperature furnace 3, a discharge delivery pipe 5, a gas barrier nozzle 6, a powder collection box 7, The atomization sealing chamber 8, the inert gas cylinder 9, the atomization sealing chamber air pressure control system 10 and two groups of ultrasonic transducers 2; the two groups of ultrasonic transducers 2 are horizontally sealed through the side of the atomization sealing chamber 8 The wall is arranged in the atomization sealing chamber 8, and the high-temperature melting furnace 3 is fixed on the top cover in the atomization sealing chamber 8 (the atomization sealing chamber 8 includes a top cover and a chamber sealed with the top cover), and the high-temperature melting furnace 3 The top of the furnace communicates with th...

specific Embodiment approach 2

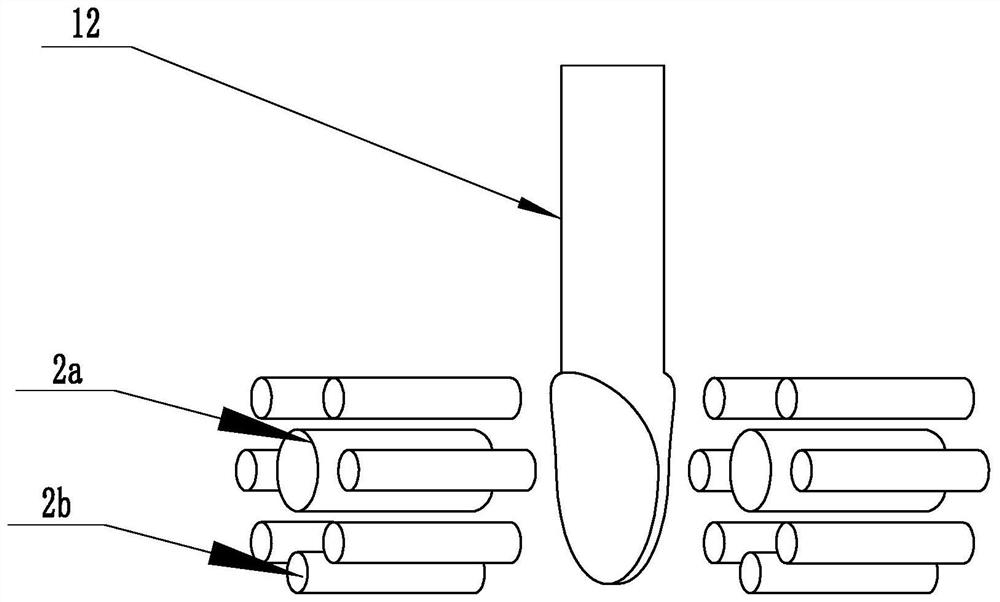

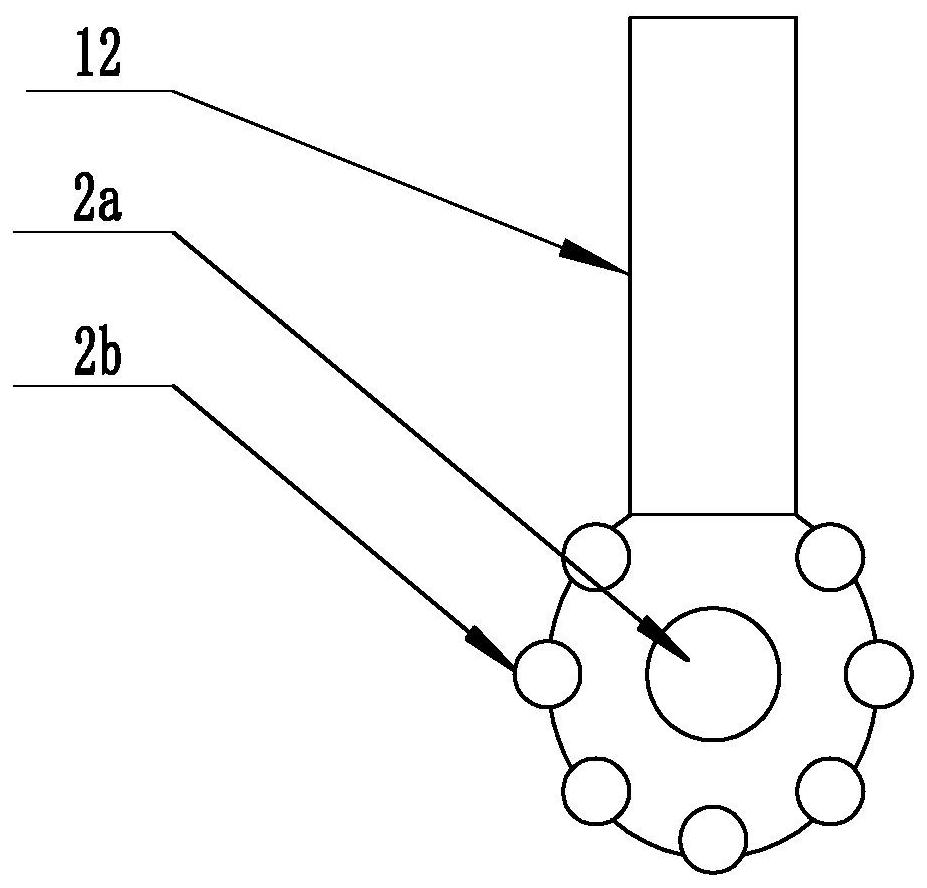

[0025] Specific implementation mode two: as Figure 1-Figure 3 As shown, this embodiment is a further description of specific embodiment 1. The main ultrasonic transducers 2a of the two groups of ultrasonic transducers 2 are located below the discharge conveying pipe 5, and the main ultrasonic transducers 2 of the two groups of ultrasonic transducers The axis of the ultrasonic transducer 2a intersects the axis of the discharge conveying pipe 5 (the ultrasonic standing waves generated by the two sets of ultrasonic transducers 2 are used to flatten the molten metal flow 12 flowing out of the discharge conveying pipe 5 to form a flat sheet , and breaks at the edges).

specific Embodiment approach 3

[0026] Specific implementation mode three: as figure 1 , figure 2 As shown, this embodiment is a further description of the specific embodiment 1. The installation axes of the auxiliary ultrasonic transducers 2b corresponding to each two of the two groups of ultrasonic transducers 2 are the same as those used by the main ultrasonic transducers. The edge of the molten metal flow 12 flattened by the sound field generated by the energy device 2a intersects (further applying sound pressure to the edge of the molten metal flow 12 to further atomize it into tiny droplets).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com