Grain depot humidity control method and its ventilating system

A ventilation system and humidity control technology, which is applied in ventilation systems, air humidification systems, space heating and ventilation, etc., can solve the problems of no humidity detection system, etc., and achieve the effects of improving grain storage conditions, ensuring safety, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

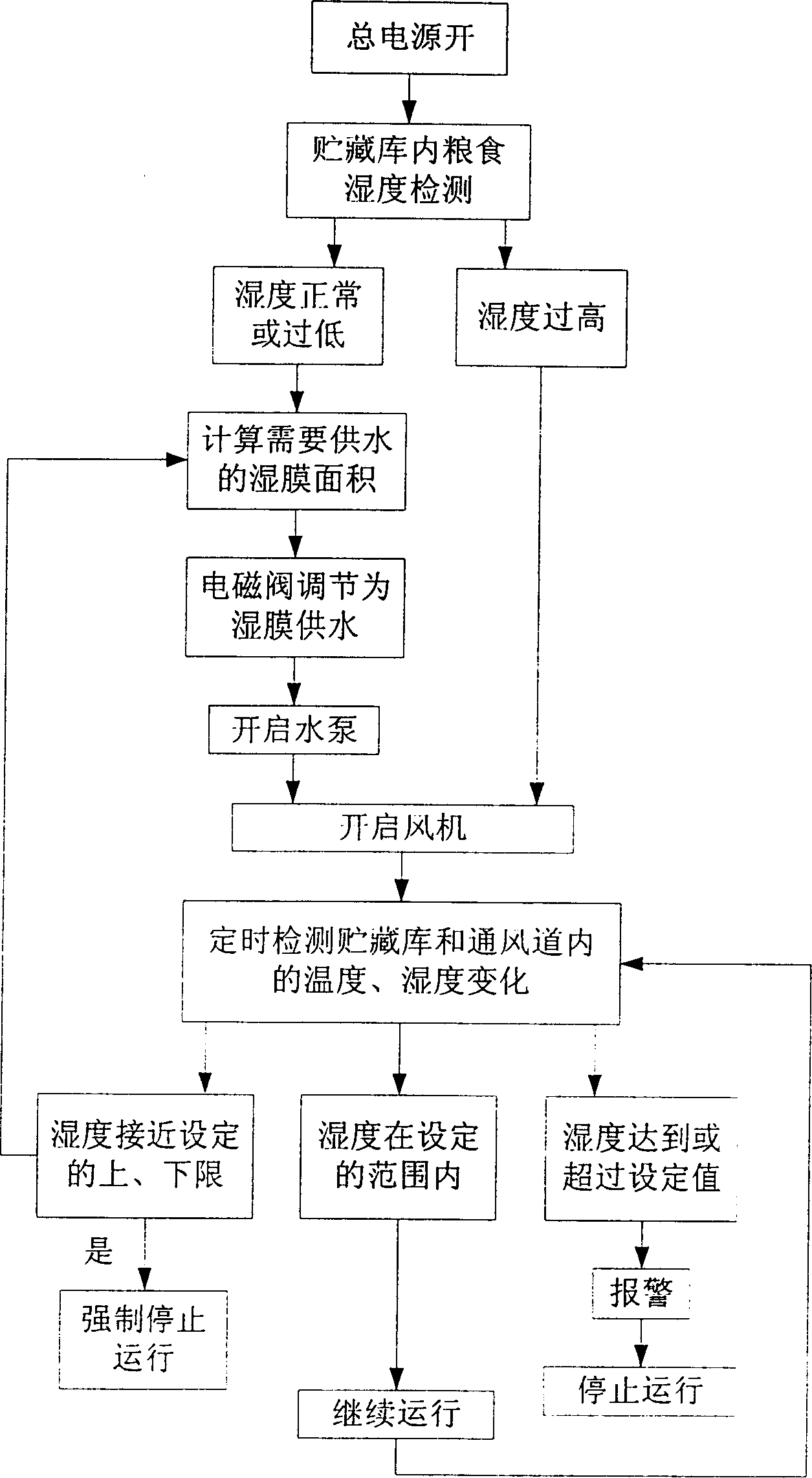

[0034] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

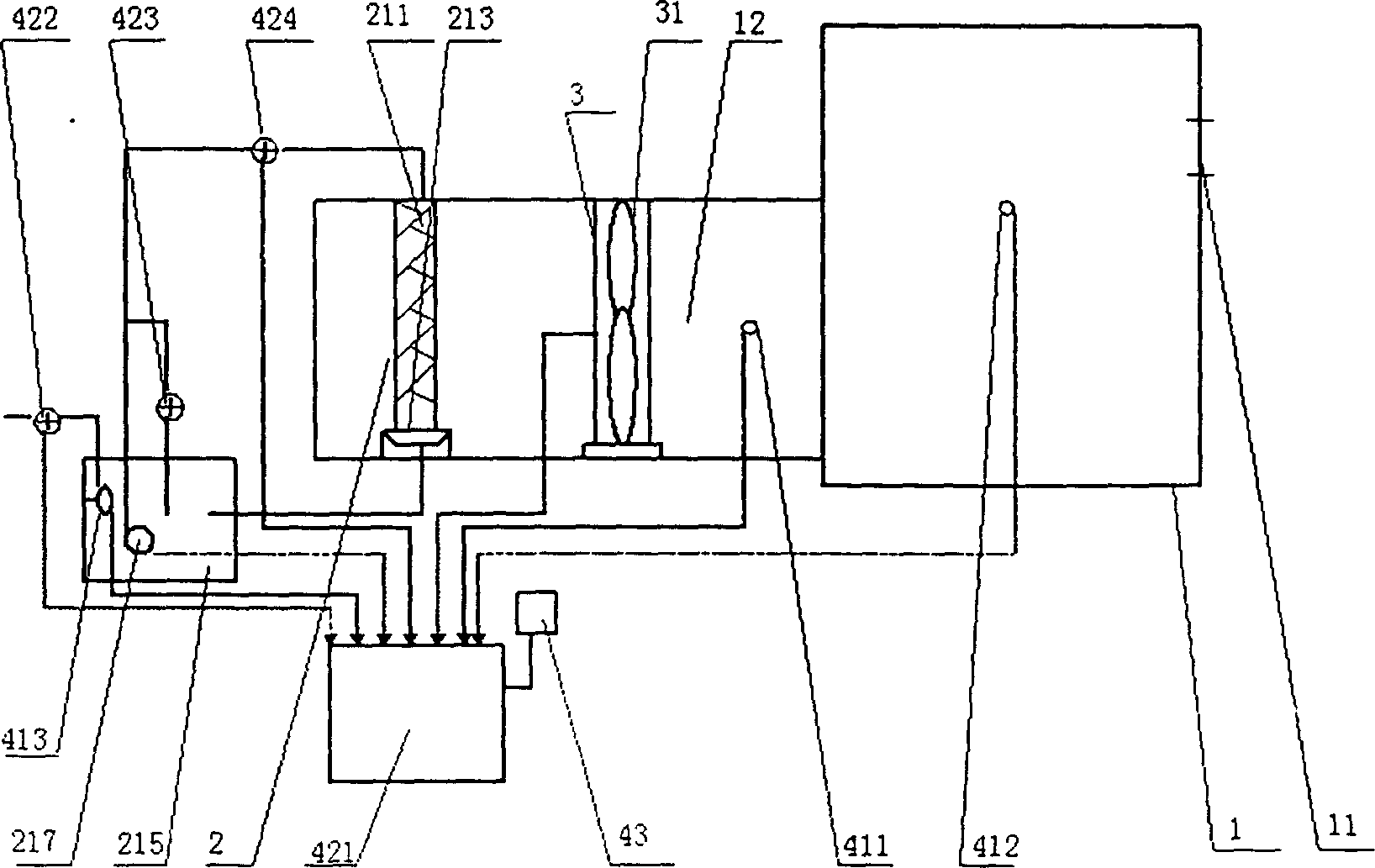

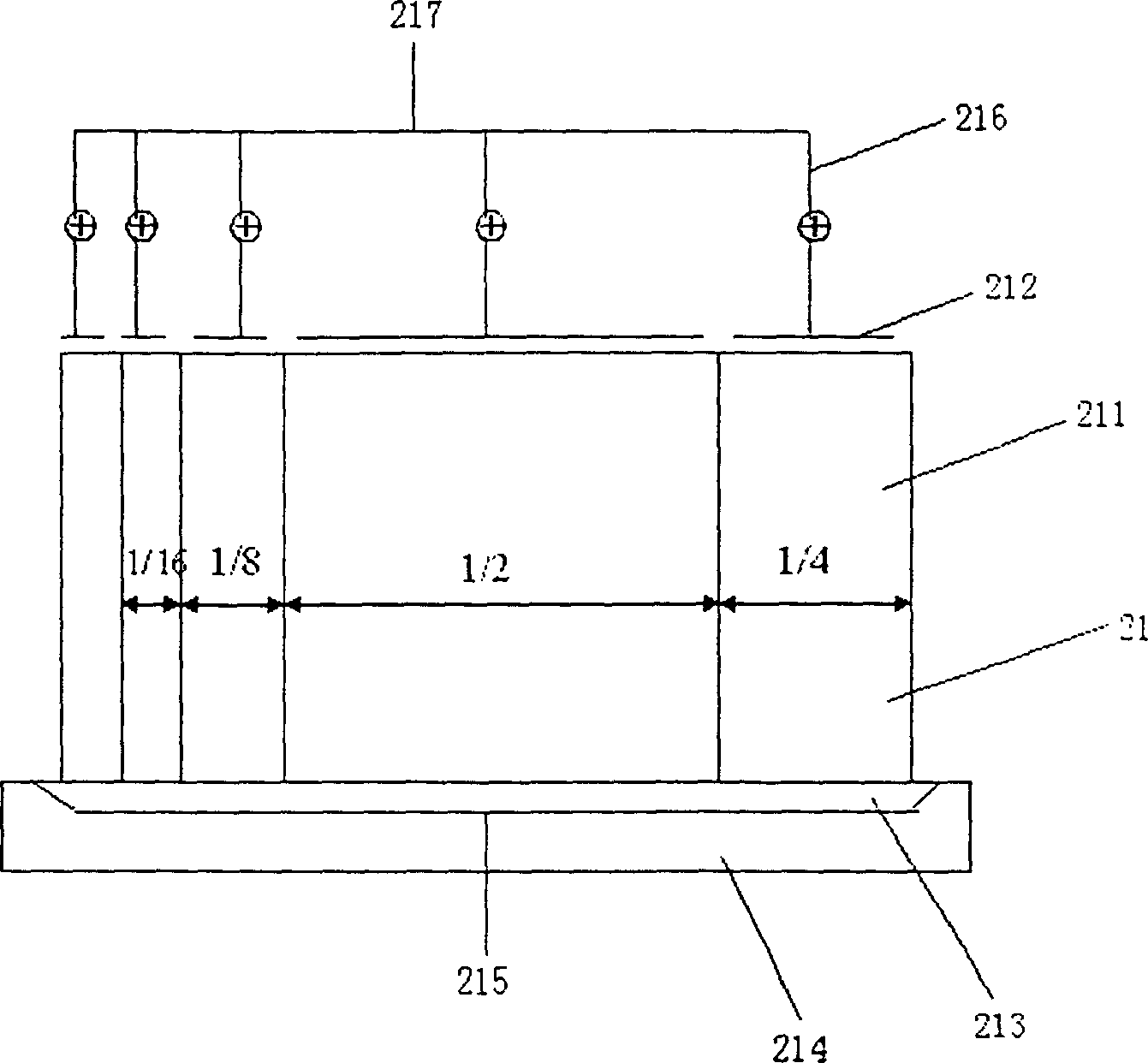

[0035] like figure 1 As shown, it is a schematic structural diagram of the wet film ventilation, moisturizing and cooling system of the present invention. from figure 1 It can be seen that the system is mainly composed of a storage room 1, a wet film module 2 and a ventilation module 3. The storage room 1 is provided with an exhaust port 11 and a ventilation channel 12. The wet film module 2 and the ventilation module 3 are arranged along the direction of entering the storage room 1. The second time is arranged in the ventilation duct 12 , and the air humidified and cooled by the wet film module 2 enters the storage room 1 through the ventilation module 3 , and is discharged through the exhaust port 11 after heat exchange.

[0036] The wet film module 2 is further provided with a detection control mechanism 4 , whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com