Semiconductor structure and forming method thereof

A semiconductor and gate structure technology, applied in the field of semiconductor structure and its formation, can solve problems such as poor device performance, achieve the effects of ensuring dimensional stability, simplifying the process, and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Currently formed devices still suffer from poor performance. The reasons for the poor performance of the device are analyzed in conjunction with a method of forming a semiconductor structure.

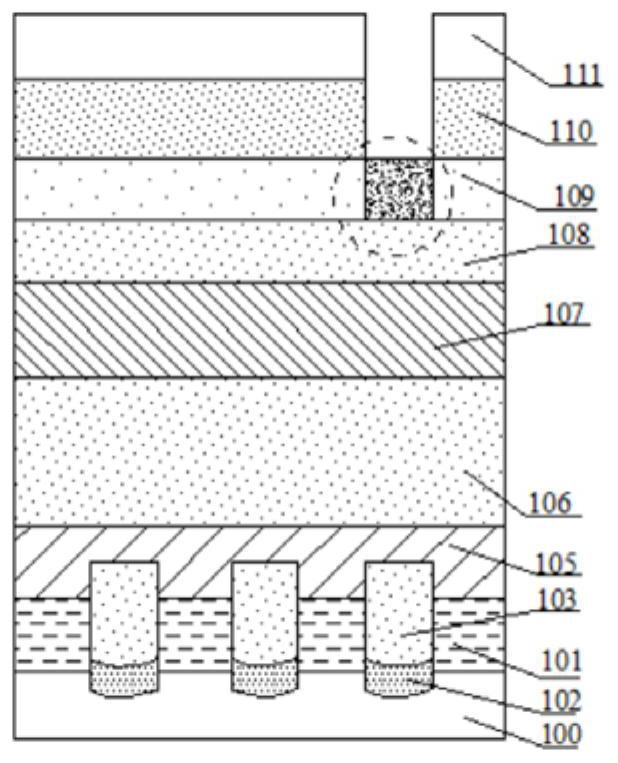

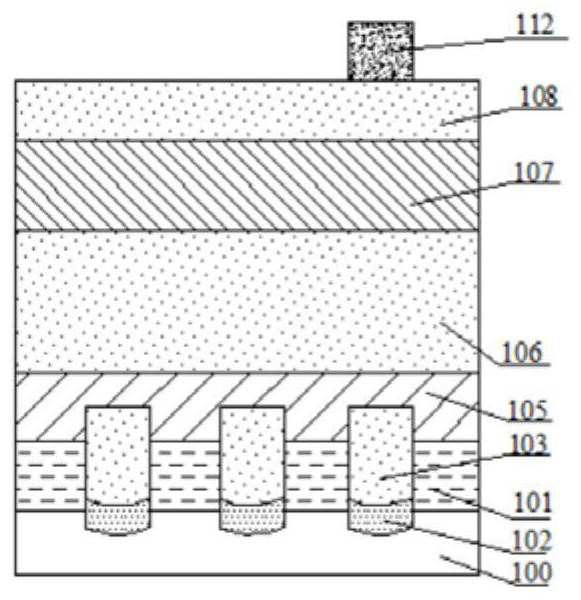

[0020] Figure 1 to Figure 9 , is a structural schematic diagram corresponding to each step in a method for forming a semiconductor structure.

[0021] like figure 1 As shown, a substrate is provided, and the substrate includes a substrate 100, a gate structure 101 on the substrate 100, a source-drain doped layer 102 on both sides of the gate structure 101, and a 101 on both sides and covering the interlayer dielectric layer 103 of the source-drain doped layer 102; on the gate structure 101 and the interlayer dielectric layer 103, a dielectric layer 106, a mask layer 107, a dielectric layer 108, and Graphic definition layer 109 . Form a first anti-reflection material layer (not shown) on the pattern definition layer 109; form a first photoresist layer 111 on the first anti-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com