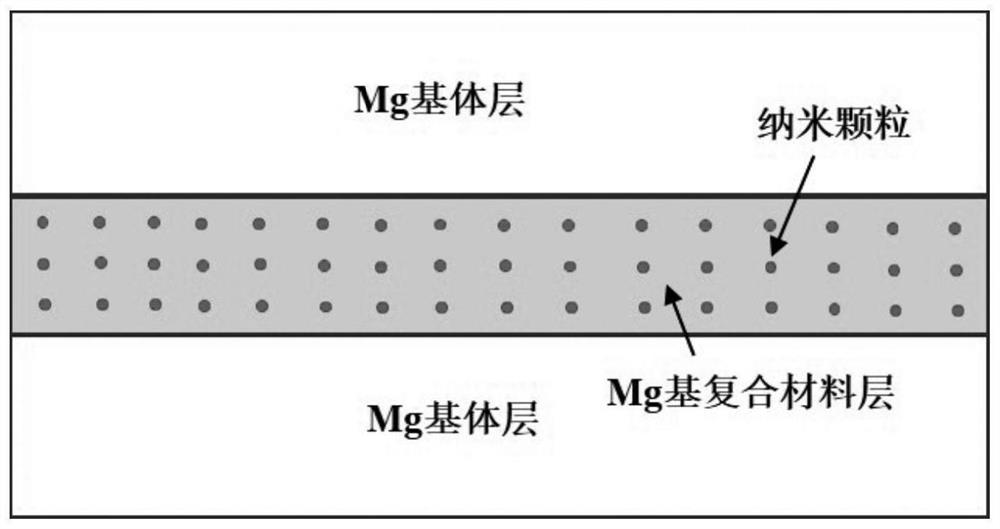

Layered magnesium-magnesium-based composite material plate as well as preparation method and application thereof

A composite material and layered technology, applied in metal rolling and other directions, can solve the problems of not constructing non-uniform magnesium-based composite materials, restricting the industrial application of magnesium-based composite material plates, and unable to solve the strength and toughness of composite materials, etc., to achieve Parameters can be adjusted arbitrarily to solve the effect of strength and ductility mismatch and stress concentration mitigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of a kind of layered magnesium-magnesium base composite plate of the present invention comprises the following steps:

[0049] S1. Put pure aluminum into a resistance furnace for heating and melting, and mix homogeneous potassium fluorotitanate K 2 TiF 6 and potassium fluoroborate KBF 4 Pour the powder into it, and cast it to obtain Al-TiB after fully reacting 2 Intermediate alloy block;

[0050] The melting temperature of pure aluminum is 800~1000℃, the atomic ratio of Ti and B in the mixed powder of potassium fluorotitanate and potassium fluoroborate is 1:2.2; the reaction time is 30~60min, Al-TiB 2 TiB in master alloy 2 The content is 5~15wt.%, TiB 2 The particle size is 50-300nm.

[0051] S2, pure Mg, pure Al, Zn ingot and the Al-TiB that step S1 makes 2 The intermediate alloy block is heated and melted under the protection of argon or JR2 covering agent, and is kept warm for a period of time, adding refining agent and vigorously stirre...

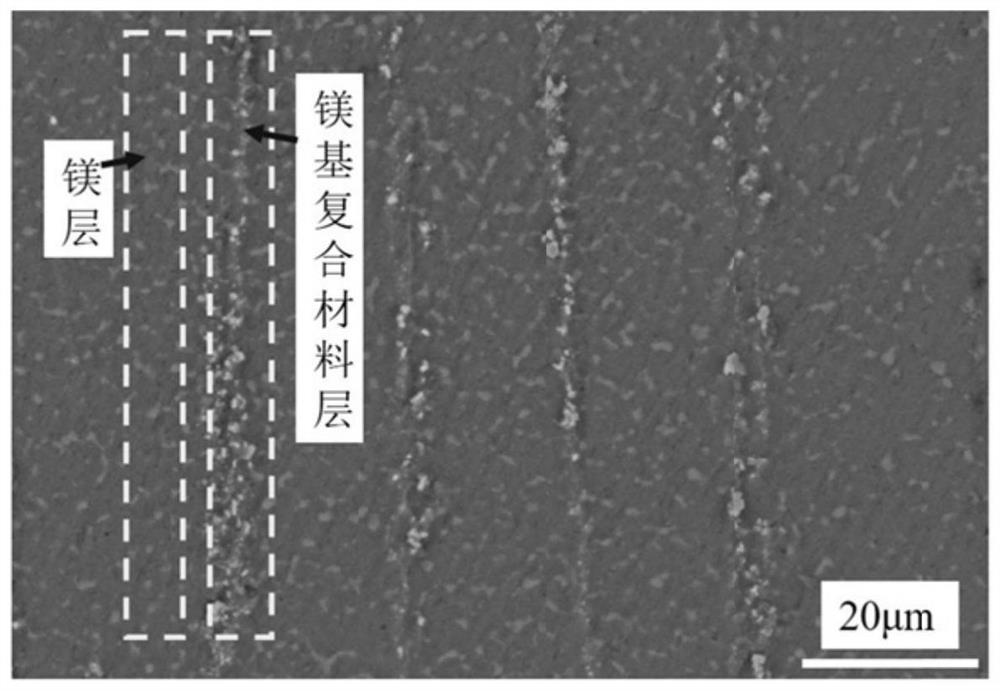

Embodiment 1

[0066] Pure aluminum is put into a resistance furnace and heated to 800°C to melt, and the evenly mixed potassium fluorotitanate K 2 TiF 6 and potassium fluoroborate KBF 4 Pour the powder (the atomic ratio of Ti to B is 1:2.2), fully react for 60 minutes and cast to obtain Al-TiB 2 Master Alloy Bulk, Al-TiB 2 TiB in master alloy 2 The content is 5wt.%, and the average size is 50nm. Pure Mg, pure Al, Zn ingots and Al-TiB 2 The master alloy block is heated to 700 ° C under the protection of argon to melt, and after 30 minutes of heat preservation, a refining agent (composition of 3536wt.% NaCl, 27wt.% CaF 2 , 38wt.% MgCl 2 ) vigorously stirred to remove surface scum, and the melt temperature was cast into a low-carbon steel mold preheated to 200°C at a temperature of 700°C to obtain an ingot.

[0067] The composite material ingot was subjected to solution treatment, the solution temperature was 380°C, and the holding time was 30h. Then perform multi-pass hot rolling, the...

Embodiment 2

[0071] Pure aluminum is put into a resistance furnace and heated to 850°C to melt, and the evenly mixed potassium fluorotitanate K 2 TiF 6 and potassium fluoroborate KBF 4 Pour the powder (the atomic ratio of Ti to B is 1:2.2), fully react for 40 minutes and cast to obtain Al-TiB 2 Master Alloy Bulk, Al-TiB 2 TiB in master alloy 2 Content at 10wt.%, size at

[0072] 120nm. Pure Mg, pure Al, Zn ingots and Al-TiB 2 The master alloy block is heated to 750°C under the protection of argon to melt, and after 10 minutes of heat preservation, a refining agent (composition of 32wt.% NaCl, 24wt.% CaF 2 , 44wt.% MgCl 2 ) vigorously stirred to remove surface scum, and the melt temperature was cast into a low-carbon steel mold preheated to 350°C at a temperature of 710°C to obtain an ingot.

[0073] The composite material ingot was subjected to solution treatment, the solution temperature was 390°C, and the holding time was 26h. Then perform multi-pass hot rolling, the annealing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com