Organosilicon modified hydroxyl polyacrylate dispersion and preparation method and application thereof

A hydroxy polyacrylate and organosilicon technology, applied in the field of coatings, can solve the problems of poor milky white appearance, small molecular weight, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

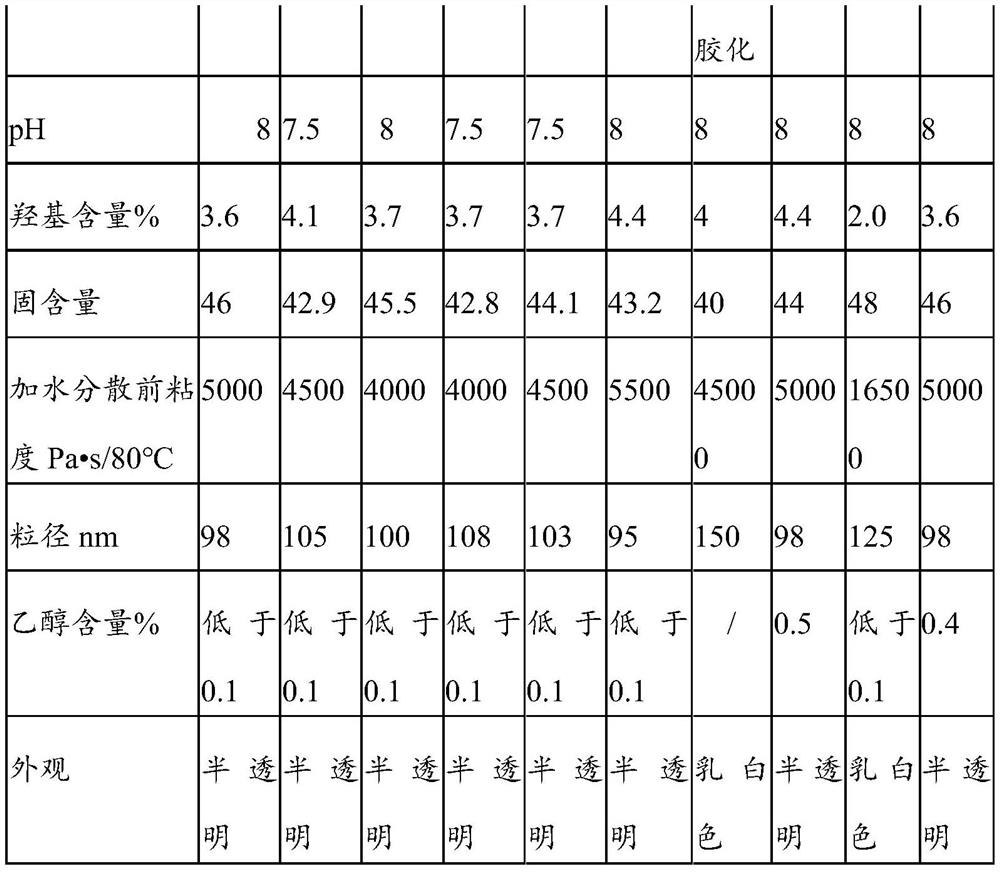

Examples

Embodiment 1

[0083] In this example, a silicone-modified hydroxyl polyacrylate dispersion was prepared:

[0084] S1. In parts by mass, 12.7 parts of acrylic acid, 9 parts of methyl methacrylate, 20 parts of styrene, 8.7 parts of butyl acrylate, 19 parts of hydroxyethyl methacrylate and 1.5 parts of di-tert-amyl peroxide Mix evenly to form a monomer mixture for subsequent use;

[0085] S2. Add 30 parts of glycidyl tert-carbonate monomer and 3.4 parts of β-(3,4-epoxycyclohexyl) ethyl Trimethoxysilane, mix and stir and heat. When the temperature reaches 145°C, start to drop the monomer mixture obtained in step S1. After 4 hours, stir and keep warm for 30 minutes. Cool down to 80°C and add 9.4 parts of isophorone. Diisocyanate, NCO / OH is 0.29:1, react for 20 minutes, use di-n-butylamine titration test - after the NCO content is 1.5%, the test viscosity is 5000mPa·s (80°C), add 3.4 parts of triethylamine, and stir for 5 minutes Add 10 parts of deionized water, react for 10 minutes, then add 1...

Embodiment 2

[0088] This embodiment has prepared a kind of waterborne two-component polyurethane coating:

[0089] Add 62 parts of the silicone-modified hydroxy polyacrylate dispersion in Example 1 into the stirring tank, and the rotation speed is 700 rpm, and pre- After mixing, add to the emulsion, add 0.2 part of defoamer, 0.8 part of thickener, 0.2 part of wetting agent, 0.3 part of neutralizing agent in sequence, disperse for 10-30 minutes, and filter out the material to obtain the main agent of water-based two-component polyurethane coating .

[0090] During construction, add 22.8 parts of water-based polyisocyanate curing agent to 100 parts of the main agent of the above-mentioned water-based two-component polyurethane coating, and stir for 5-8 minutes to obtain the water-based two-component polyurethane coating.

[0091] The molar ratio of NCO groups in the curing agent to OH groups in the main agent is 1.8:1.

[0092] The defoamer is TEGO-800;

[0093] The thickener is RM-8W;

...

Embodiment 3

[0098] In this example, a silicone-modified hydroxyl polyacrylate dispersion was prepared:

[0099] S1. In parts by mass, 15 parts of methacrylic acid, 15 parts of methyl methacrylate, 15.1 parts of styrene, 6 parts of butyl acrylate, 20 parts of hydroxyethyl acrylate, 2 parts of di-tert-amyl peroxide Mix evenly to form a monomer mixture for subsequent use;

[0100] S2. Add 30 parts of 4-tert-butyl glycidyl benzoate monomer and 2.8 parts of γ-glycidyl ether propyl trimethoxy in a four-necked flask equipped with a thermometer, condenser tube, stirring paddle and constant pressure dropping funnel base silane, mixed and stirred and heated. When the temperature reached 140°C, the monomer mixture obtained in step S1 was added dropwise. After 4.5 hours, the drop was completed. Isocyanate, NCO / OH is 0.23:1, react for 20min, use di-n-butylamine titration test-after the NCO content is 1.3%, the test viscosity is 4500mPa·s (80°C), add 3.2 parts of triethylamine, stir for 3min and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com