Antibacterial lining aluminum plate applied to household appliances and preparation method of antibacterial lining aluminum plate

An aluminum plate and lining technology, which is applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., which can solve the problems of low bonding strength, single antibacterial function, and poor antibacterial durability of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

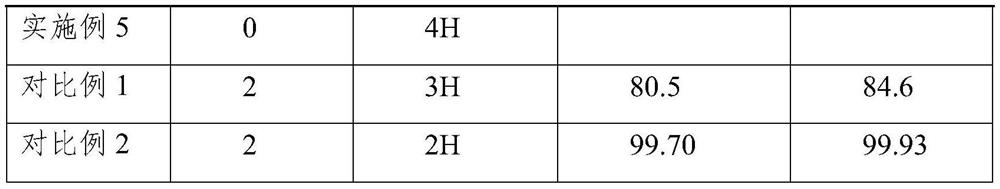

Examples

preparation example Construction

[0023] Preferably, the N-[4-(sulfonamide) phenyl]acrylamide / 3-allyl benzothiazolium bromide / N-trimethylolmethacrylamide / glycidyl methacrylate copolymer The preparation method of thing, comprises the steps:

[0024] Step S101, N-[4-(sulfonamide)phenyl]acrylamide, 3-allylbenzothiazolium bromide, N-trimethylolmethacrylamide, glycidyl methacrylate, initiator The agent is added to the high boiling point solvent, stirred and reacted at 50-65°C for 4-6 hours in an inert gas atmosphere, and then precipitated in water, then washed with ethanol for 3-6 times, and finally placed in vacuum drying Dry in oven at 85-95°C to constant weight;

[0025] Step S102, soak the polymer produced in step S101 in malic acid aqueous solution at 50-60°C for 18-24 hours, take it out, wash it with water for 3-6 times, and finally dry it in a vacuum drying oven at 85-95°C to constant weight.

[0026] Preferably, N-[4-(sulfonamide) phenyl] acrylamide, 3-allyl benzothiazolium bromide, N-trimethylol methacr...

Embodiment 1

[0038]This example provides a kind of antibacterial lining aluminum plate that is applied to household appliances, comprises aluminum plate and the antibacterial coating that is covered on the surface of aluminum plate; Described antibacterial coating comprises the following components by weight and is made: N-[4-( Sulfonamide) phenyl] acrylamide / 3-allyl benzothiazolium bromide / N-trimethylolmethacrylamide / glycidyl methacrylate copolymer 45 parts, 2,2-bis[4 -(4-aminophenoxy)phenyl]-1,1,1,3,3,3-hexafluoropropane 4 parts, dihydroxyaminoacetate aluminum 0.8 parts, filler 10 parts, dispersant 1 part, defoamer 0.5 parts of agent, 0.3 parts of leveling agent, and 40 parts of solvent; the thickness of the aluminum plate is not more than 1mm.

[0039] Preparation of the N-[4-(sulfonamide) phenyl]acrylamide / 3-allyl benzothiazolium bromide / N-trimethylolmethacrylamide / glycidyl methacrylate copolymer method, comprising the steps of:

[0040] Step S101, N-[4-(sulfonamide)phenyl]acrylamide...

Embodiment 2

[0047] This example provides an antibacterial lining aluminum plate applied to household appliances and a preparation method thereof, which is basically the same as in Example 1, except that the antibacterial coating includes the following components in parts by weight: N- [4-(sulfonamide)phenyl]acrylamide / 3-allylbenzothiazolium bromide / N-trimethylolmethacrylamide / glycidyl methacrylate copolymer 50 parts, 2,2 -4.5 parts of bis[4-(4-aminophenoxy)phenyl]-1,1,1,3,3,3-hexafluoropropane, 0.9 parts of dihydroxyaminoacetate aluminum, 12 parts of filler, 1.2 parts of dispersant parts, 0.7 parts of defoamer, 0.4 parts of leveling agent, and 43 parts of solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com