Polymer composite microsphere as well as preparation method and application thereof

A technology of composite microspheres and macromolecules, which is applied in the directions of non-active ingredients of macromolecular compounds, medical preparations of non-active ingredients, and medical preparations containing active ingredients, etc. Problems such as poor batch stability and uncontrollable degradation behavior of microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

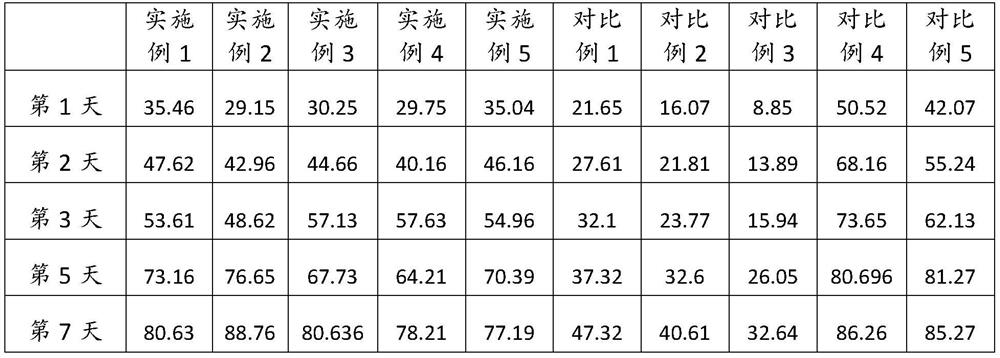

Examples

Embodiment 1

[0072] In this embodiment, a polymer composite microsphere is prepared, and the specific process is as follows:

[0073] D1. Mix 100mg of naringin with 4mL of an aqueous solution containing 100mg / mL of polyethyleneimine, and stir at 20000rpm for 8min;

[0074] Continue to stir at 3000 rpm for 2 hours at 60°C under nitrogen protection to carry out the wrapping reaction;

[0075] After the reaction was completed, the mixture was centrifugally washed with deionized water for 5 times (the mass volume ratio of each cleaning solid to deionized water was 1:200g / ml), freeze-dried for 48 hours to obtain drug granules;

[0076] D2. Dissolve 2 g of polylactic acid-glycolic acid copolymer (molecular weight is about 30,000 Daltons) in 10 mL of dichloromethane, then add 4,000 mg of the drug granules obtained in step D1, and then stir at 10,000 rpm for 5 min;

[0077] D3. The mixture obtained in step D2 was poured into 300 mL of an aqueous solution containing 1% polyvinyl alcohol 1799, stir...

Embodiment 2

[0080] In this embodiment, a polymer composite microsphere is prepared, and the specific process is as follows:

[0081] D1. 100mg melatonin was mixed with 4.5mL aqueous solution containing 200mg / mL carboxymethyl chitosan, stirred at 12000rpm for 10min;

[0082] Pour it into a 1mol / L sodium hydroxide solution at 95°C under nitrogen protection, and continue to stir at 2500rpm for 4h;

[0083] After the reaction, centrifuge and wash 7 times with deionized water (the mass volume ratio of solid to deionized water is 1:150g / ml), and freeze-dry for 48 hours to obtain drug particles;

[0084] D2. Dissolve 3.6g of poly 3-hydroxybutyrate-co-3-hydroxyvalerate (molecular weight is about 150,000 Daltons) in 10mL of tetrahydrofuran, then add 800mg of the drug granules obtained in step D1, and stir at 18000rpm 2min;

[0085] D3. Pour the mixture obtained in step D2 into 400 mL of an aqueous solution containing 0.8% polyvinyl alcohol 1788, continue stirring at 1500 rpm for 15 h, and then c...

Embodiment 3

[0088] In this embodiment, a polymer composite microsphere is prepared, and the specific process is as follows:

[0089] D1. Mix 100mg of resveratrol with 10mL of an aqueous solution containing 70mg / mL of polyethyleneimine, and stir at 18000rpm for 15min;

[0090] 60°C, under the protection of nitrogen, continue to stir at 4000rpm for 1h to carry out the coating reaction;

[0091] After the reaction, centrifuge and wash the solid with deionized water (the mass volume ratio of solid to deionized water is 1:250g / ml) and freeze-dry the obtained solid for 8 times for 48 hours to obtain drug granules;

[0092] D2. Dissolve 1.4g of polylactic acid (molecular weight is about 3,000 Daltons) in 10mL of dichloromethane, then add 600mg of the drug granules obtained in step D1, and then stir at 12000rpm for 8min;

[0093] D3. Pour the mixture obtained in step D2 into 200 mL of an aqueous solution containing 1.5% methylcellulose, continue stirring at 1000 rpm for 18 hours, and then centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com