Polishing and cleaning device for mechanical part machining and working method of polishing and cleaning device

A technology for mechanical parts and cleaning devices, used in grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc. Efficiency, convenient centralized collection and treatment, and the effect of reducing the degree of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

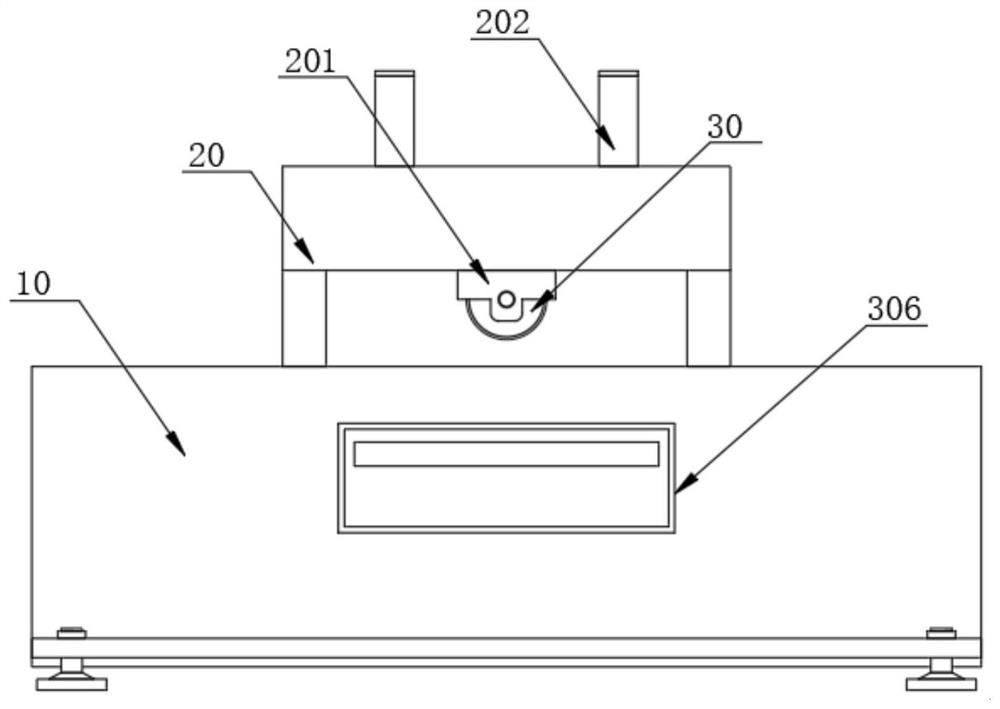

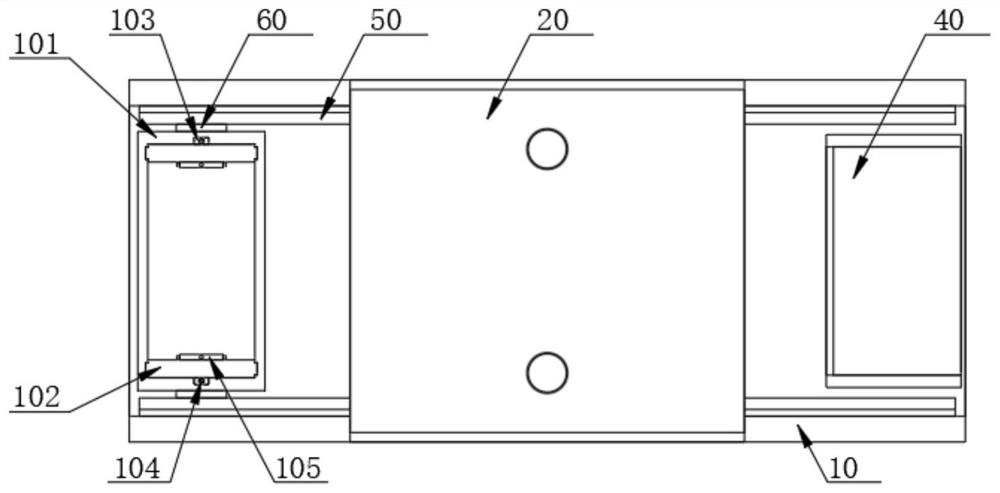

[0037] see Figure 1-8 As shown, a grinding and cleaning device for machining mechanical parts includes a frame 10 and an installation frame 20. The installation frame 20 is arranged on the top of the frame 10, and a grinding wheel 30 is arranged inside the installation frame 20. The top of the frame 10 is provided with a grinding wheel 30. The left side is provided with a fixing mechanism, and the right side of the top of the rack 10 is provided with a discharge rack 40, the front and rear of the inner wall of the rack 10 are provided with linear slide rails 50, and the opposite sides of the two linear slide rails 50 are slid A linear motor 60 is arranged, an adjustment mechanism is arranged above the inside of the mounting frame 20, and a recovery mechanism is arranged inside the frame 10 and located just below the installation frame 20;

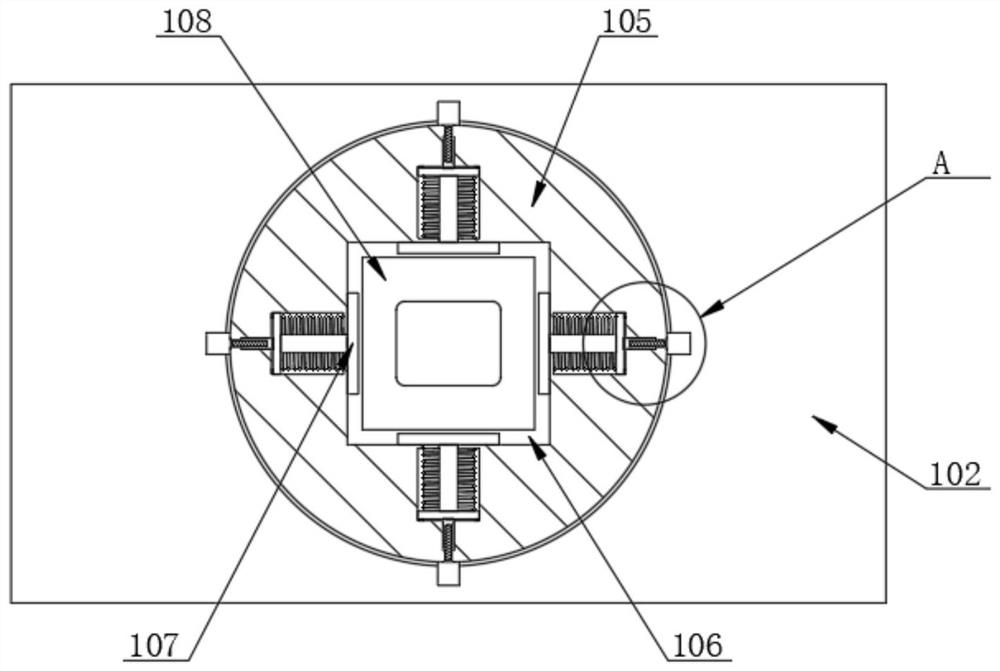

[0038] The fixing mechanism includes a fixing frame 101, and the front and rear sides of the fixing frame 101 are respectively fixedly co...

Embodiment 2

[0045] In the present invention, the telescopic assembly includes a movable rod 401, and one end of the movable rod 401 is fixedly connected to one side of the limit plate 107, the limit frame 105 is provided with a movable slot 402, and the inner of the movable slot 402 is slidably provided with a sliding plate 403 , one end of the movable rod 401 is fixedly connected with one side of the slide plate 403 , and the surface of the movable rod 401 is sleeved with a second spring 404 , a push rod 405 is slidably provided inside the limit frame 105 , and the inner screw connection of the push rod 405 There is a second screw 406, the peripheral surface of the limit frame 105 is provided with a second servo motor 407, and one end of the output shaft of the second servo motor 407 is fixedly connected with one end of the second screw 406 through a coupling;

[0046] Servo motor II 407 is used to drive the second screw 406 to rotate, and the second screw 406 makes one end of the push ro...

Embodiment 3

[0048] In the present invention, the inside of the movable frame 201 is also provided with air pumps 501, and two air pumps 501 are symmetrically arranged inside the installation frame 20, and both sides of the bottom of the movable frame 201 are provided with connecting grooves 502 which are matched with the connecting plate 303. And one end of the air outlets of the two air pumps 501 extends to the inside of the two connecting grooves 502 respectively. When the movable plate 301 is pushed up, the tops of the two connecting plates 303 are inserted into the inside of the two connecting grooves 502 respectively. When the parts are polished, air is blown into the air passages inside the two connecting plates 303 through the two air pumps 501, the air is blown on the surface of the mechanical parts, and the waste chips generated during the grinding process are blown into the blanking chute 305, It avoids the impact of grinding waste on grinding, and at the same time quickly collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com